Warehouse Inventory Management

Sean, Industry Editor

Sep 28, 2024

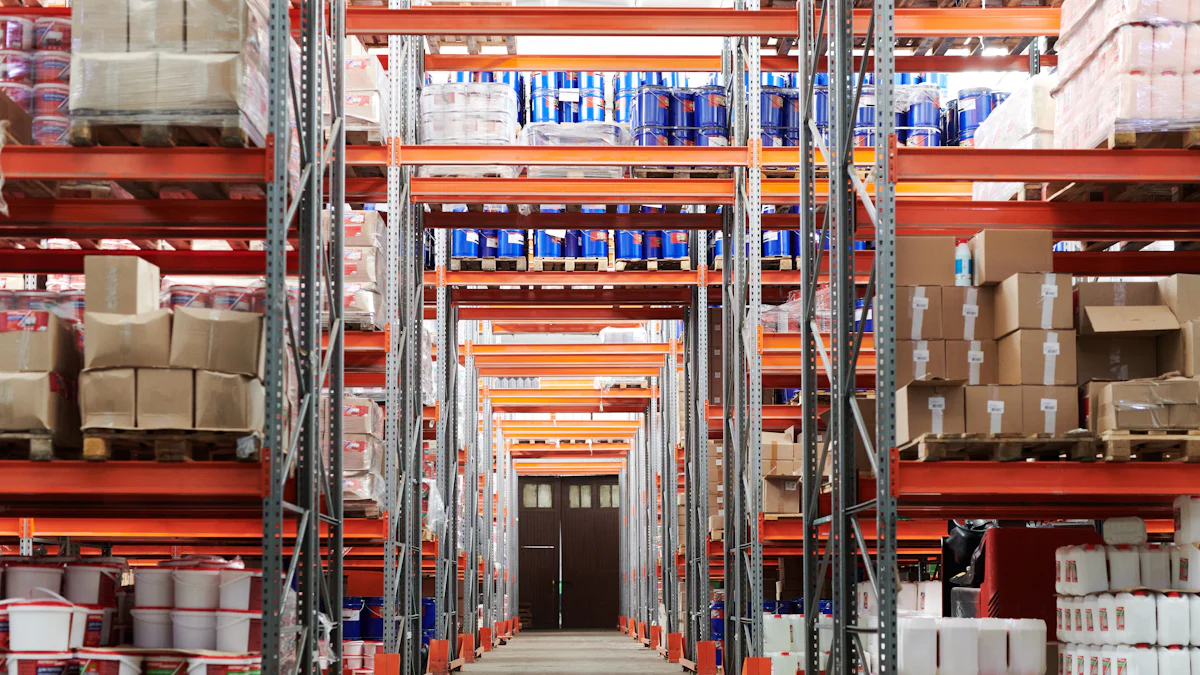

Warehouse Inventory Management involves receiving, storing, and tracking inventory within a warehouse. This process ensures optimal inventory levels, which prevents overspending on storage and minimizes losses. Businesses benefit from efficient inventory management by reducing costs and improving cash flow. Meeting customer demands with timely deliveries enhances satisfaction. Warehouse Inventory Management plays a crucial role in business operations by forecasting sales trends and streamlining processes. Effective management leads to lower costs and improved resource utilization.

Understanding Warehouse Inventory Management

Definition and Scope of Warehouse Inventory Management

Warehouse Inventory Management involves several key activities. Businesses receive goods into the warehouse. Staff members store these goods in designated areas. Tracking inventory levels occurs regularly. Managers oversee the movement of goods within the warehouse.

Key Components

Several components make up Warehouse Inventory Management. Receiving involves checking goods upon arrival. Storing requires placing goods in appropriate locations. Picking involves selecting items for orders. Packing ensures items are ready for shipping. Shipping involves sending goods to customers.

Objectives

Warehouse Inventory Management aims to achieve specific objectives. Businesses strive to maintain optimal inventory levels. Managers aim to reduce storage costs. Efficient processes help meet customer demands. Timely deliveries enhance customer satisfaction. Effective management improves cash flow.

Inventory vs. Stock

Inventory and stock often seem similar. However, differences exist between the two terms.

Differences

Inventory includes all goods within a warehouse. Stock refers to items available for sale. Inventory encompasses raw materials, work-in-progress, and finished goods. Stock focuses on products ready for customers.

Similarities

Inventory and stock share common traits. Both involve tracking quantities. Businesses manage both to meet customer needs. Accurate records ensure efficient operations. Proper management prevents shortages and excesses.

Importance of Warehouse Inventory Management

Operational Efficiency

Warehouse Inventory Management plays a vital role in enhancing operational efficiency. Businesses must focus on streamlining processes to achieve this goal.

Streamlining Processes

Efficient processes ensure smooth operations within the warehouse. Managers should implement strategies that optimize workflow. Best Buy's ship-from-store strategy serves as an example. This approach reduced delivery times and improved inventory turnover. Businesses can adopt similar strategies to enhance efficiency.

Reducing Waste

Reducing waste is crucial for cost savings. Effective management minimizes excess inventory. Turvo's approach highlights efficient stock rotation and storage methods. Real-time visibility into inventory levels prevents overstocking. Businesses benefit from decreased holding costs and improved cash flow.

Customer Satisfaction

Meeting customer expectations is essential for business success. Warehouse Inventory Management directly impacts customer satisfaction.

Meeting Demand

Businesses must maintain optimal inventory levels to meet demand. Proper management ensures products are always available. Customers receive their desired items without delay. This approach prevents lost sales and enhances customer loyalty.

Timely Deliveries

Timely deliveries are crucial for customer satisfaction. Efficient inventory management supports prompt shipping. Best Buy's strategy demonstrated improved delivery times. Businesses can achieve similar results with effective management. Customers appreciate timely service, leading to repeat business.

Methods of Warehouse Inventory Management

Just-In-Time (JIT)

The Just-In-Time method focuses on reducing inventory levels by receiving goods only as needed. This approach minimizes waste and enhances efficiency.

Advantages

-

Cost Savings: JIT reduces holding costs by minimizing excess inventory.

-

Improved Cash Flow: Businesses maintain optimal cash flow with fewer resources tied up in stock.

-

Increased Efficiency: Streamlined operations lead to faster response times to market demands.

Disadvantages

-

Supply Chain Risks: Any disruption can lead to stockouts due to minimal buffer stock.

-

High Dependence on Suppliers: Reliable suppliers are crucial for timely deliveries.

-

Limited Flexibility: Rapid changes in demand may challenge the system's responsiveness.

ABC Analysis

ABC Analysis classifies inventory items based on their importance and contribution to sales. This method helps prioritize resources and manage inventory effectively.

Classification

-

Category A: High-value items with significant impact on sales. These require close monitoring.

-

Category B: Moderate-value items with average sales impact. Regular review is necessary.

-

Category C: Low-value items with minimal sales impact. Less frequent checks suffice.

Implementation

-

Resource Allocation: Allocate more resources to manage Category A items.

-

Inventory Levels: Adjust inventory levels based on classification to optimize storage.

-

Focus on Key Items: Prioritize efforts on items that contribute most to revenue.

Warehouse Inventory Management benefits greatly from these methods. Businesses achieve improved efficiency, cost savings, and enhanced customer satisfaction through strategic implementation.

Warehouse Inventory Management Systems

Manual Systems

Manual systems rely on traditional methods. Employees use pen and paper to track inventory. Small businesses often find this approach viable.

Pros

-

Low Cost: Manual systems require minimal investment.

-

Simplicity: Employees can easily understand and implement these systems.

-

Flexibility: Businesses can adapt manual processes to specific needs.

Cons

-

Time-Consuming: Manual tracking takes significant time and effort.

-

Error-Prone: Human errors can lead to inaccuracies.

-

Limited Scalability: Growth becomes challenging with manual systems.

Automated Systems

Automated systems use advanced technology. Businesses employ tools like RFID tags, sensors, and drones. These systems offer real-time tracking and management.

Features

-

Real-Time Data: Automated systems provide instant updates on inventory levels.

-

Advanced Tracking: Technologies like RFID improve accuracy.

-

Integration: Systems integrate with other business operations for seamless management.

Benefits

-

Increased Efficiency: Automation reduces manual labor and speeds up processes.

-

Improved Accuracy: Real-time data minimizes discrepancies and stockouts.

-

Scalability: Businesses can easily expand operations with automated solutions.

Warehouse Inventory Management benefits greatly from these systems. Automated solutions enhance efficiency and accuracy. Businesses achieve better control over inventory and meet customer demands effectively.

Challenges in Warehouse Inventory Management

Warehouse Inventory Management faces several challenges that can disrupt operations and affect business performance. Understanding these challenges helps businesses implement effective solutions.

Common Issues

Overstocking

Overstocking occurs when inventory levels exceed demand. Businesses often increase order sizes to take advantage of supplier discounts. However, this strategy can lead to high holding costs. Excess inventory ties up capital and increases storage expenses. Overstocking also risks product obsolescence, leading to potential losses.

Stockouts

Stockouts happen when inventory levels fall below demand. This issue leads to lost sales and dissatisfied customers. Stockouts occur due to inaccurate demand forecasting or delayed replenishment. Businesses must address stockouts promptly to maintain customer trust and avoid revenue loss.

Solutions

Technology Integration

Technology integration offers a powerful solution to inventory challenges. Inventory tracking systems like RFID technology provide real-time visibility into stock levels. These systems improve accuracy and reduce discrepancies. Businesses can make informed decisions to rectify stock imbalances quickly. Target's investment in technology helped the company adapt to changing consumer behaviors. The robust system allowed Target to avoid significant stockouts during the pandemic.

Staff Training

Staff training plays a crucial role in effective Warehouse Inventory Management. Employees need proper training to handle inventory accurately. Training programs should focus on inventory counting and data entry skills. Well-trained staff can minimize errors and improve inventory accuracy. Businesses benefit from reduced discrepancies and enhanced operational efficiency.

Benefits of Effective Warehouse Inventory Management

Cost Savings

Reduced Holding Costs

Effective Warehouse Inventory Management reduces holding costs significantly. Businesses optimize storage space by maintaining optimal inventory levels. Overstocking leads to increased expenses. Proper management prevents this issue. Efficient systems ensure goods move quickly through the warehouse. This approach minimizes the need for excessive storage.

Improved Cash Flow

Businesses experience improved cash flow with effective inventory management. Resources remain available for other investments. Companies avoid tying up capital in unsold stock. Timely replenishment and accurate demand forecasting contribute to financial stability. Businesses can allocate funds more strategically.

Enhanced Productivity

Efficient Resource Utilization

Warehouse Inventory Management enhances resource utilization. Employees work more efficiently with streamlined processes. Automated systems reduce manual labor. Staff focus on tasks that add value. Efficient workflows lead to higher productivity levels. Businesses achieve more with fewer resources.

Better Decision Making

Accurate data supports better decision making. Managers access real-time information about inventory levels. This insight allows for informed choices. Businesses respond quickly to market changes. Improved decision making leads to increased competitiveness. Companies stay ahead by adapting strategies based on reliable data.

Future Trends in Warehouse Inventory Management

Technological Advancements

AI and Machine Learning

AI and Machine Learning transform Warehouse Inventory Management. These technologies predict demand patterns. Businesses optimize stock levels with accurate forecasts. AI analyzes large data sets quickly. Machine Learning improves decision-making processes. Companies enhance efficiency by automating routine tasks.

IoT and Automation

IoT and Automation revolutionize inventory tracking. Sensors provide real-time updates on stock levels. Automated systems streamline warehouse operations. Drones and robots assist in moving goods efficiently. Businesses reduce human error with these technologies. IoT devices ensure seamless integration across supply chains.

Sustainability Practices

Eco-friendly Solutions

Eco-friendly solutions gain importance in Warehouse Inventory Management. Businesses adopt sustainable packaging materials. Energy-efficient lighting reduces operational costs. Solar panels power warehouses, decreasing carbon footprints. Companies prioritize green practices to meet environmental standards.

Waste Reduction

Waste reduction remains a key focus for businesses. Efficient inventory management minimizes excess stock. Companies implement recycling programs for unused materials. Real-time data helps avoid overproduction. Businesses achieve cost savings through reduced waste.

Effective Warehouse Inventory Management is crucial for achieving operational excellence. Businesses must maintain optimal inventory levels to meet customer demands and reduce costs. Efficient management minimizes holding expenses and enhances cash flow. Implementing strategies discussed in this blog helps businesses stay competitive. Companies should focus on streamlining processes and integrating technology. These actions lead to improved productivity and customer satisfaction. Adopting these practices ensures businesses remain agile in a dynamic market environment.

FAQ

Warehouse inventory management involves receiving, storing, and tracking goods within a warehouse. Managers oversee the movement of inventory to maintain optimal levels.

Effective management ensures businesses meet customer demands. Proper inventory levels prevent stockouts and overstocking. Companies save costs and improve cash flow.

Inventory management covers all goods in a warehouse. Stock management focuses on items available for sale. Inventory includes raw materials and finished goods. Stock pertains to products ready for customers.

Overstocking and stockouts pose significant challenges. Overstocking ties up capital and increases storage costs. Stockouts lead to lost sales and dissatisfied customers.

Technology provides real-time visibility into inventory levels. Systems like RFID reduce discrepancies and improve accuracy. Businesses make informed decisions quickly.

Just-In-Time (JIT) and ABC Analysis enhance efficiency. JIT minimizes waste by receiving goods as needed. ABC Analysis prioritizes resources based on item importance.

Automated systems increase efficiency and accuracy. Real-time data updates improve decision-making. Businesses scale operations easily with automation.

Effective management reduces holding costs and improves cash flow. Companies optimize storage space and avoid tying up capital in unsold stock.

AI and Machine Learning predict demand patterns. IoT and Automation streamline operations. Businesses adopt eco-friendly solutions to reduce waste.

Continue Reading About Warehouse Inventory Management

2025 Best Data Integration Solutions and Selection Guide

Explore top data integration solutions for 2025, enhancing data management and operational efficiency with leading platforms like Fivetran and Talend.

Howard

Dec 19, 2024

Best Data Integration Platforms to Use in 2025

Explore the best data integration platforms for 2025, including cloud-based, on-premises, and hybrid solutions. Learn about key features, benefits, and top players.

Howard

Jun 20, 2024

Best Data Integration Vendors for Seamless Workflows

Discover the top 20 data integration vendors of 2025 for seamless workflows. Compare tools like Talend, AWS Glue, and Fivetran to optimize your data processes.

Howard

Jan 22, 2025

Customer Data Integration: A Comprehensive Guide

Master customer data integration to enhance business operations by combining data from multiple sources for a comprehensive customer view.

Howard

Sep 07, 2024

Data Validation Techniques: Secrets to Achieving Precision and Accuracy

Master data validation techniques from manual to machine learning methods. Ensure data quality with our practical steps.

Howard

Aug 06, 2024

Best Data Management Tools of 2025

Explore the best data management tools of 2025, including FineDataLink, Talend, and Snowflake. Learn about their features, pros, cons, and ideal use cases.

Howard

Aug 04, 2024