Supply Chain Execution involves managing the flow of goods from procurement to delivery. This process plays a crucial role in business success. Companies with efficient supply chains often see significant revenue growth. In fact, 79% of high-performing supply chains achieve above-average revenue growth. Understanding this concept is vital for gaining a competitive edge. A well-executed supply chain can enhance customer satisfaction and reduce costs, making it an essential focus for any business.

Understanding Supply Chain Execution

Definition and Scope of Supply Chain Execution

Supply Chain Execution involves the practical implementation of supply chain activities. You manage the flow of goods from procurement to delivery. This process includes several key components:

Key Components

- Procurement: Acquiring raw materials or products.

- Production: Transforming materials into finished goods.

- Warehousing: Storing products until they are needed.

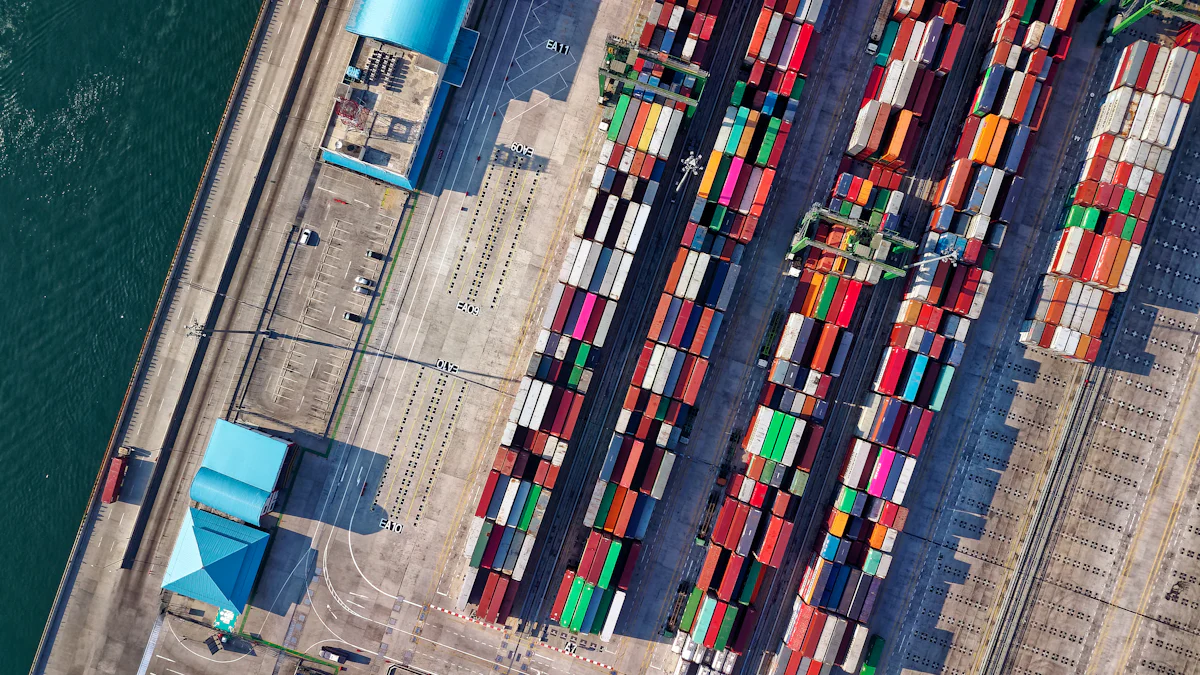

- Transportation: Moving goods to their final destination.

These components work together to ensure products reach customers efficiently.

Differences from Supply Chain Management

While Supply Chain Management focuses on planning and strategy, Supply Chain Execution emphasizes action. You put plans into practice, ensuring that operations run smoothly. Execution deals with the day-to-day activities that keep the supply chain moving.

Historical Context of Supply Chain Execution

Understanding the history of Supply Chain Execution helps you appreciate its evolution.

Evolution Over Time

In the 1960s to 1980s, supply chains became more efficient through computerization. Automation and analytics improved processes. The 1980s saw a transformation with personal computing. New technologies like flexible spreadsheets and map-based interfaces enhanced logistics.

Technological Advancements

The term 'Supply Chain Management' was coined in 1983. This era brought innovations like air freight optimization and ERP systems. These advancements revolutionized how you manage supply chains, making them more effective and responsive.

Core Elements of Supply Chain Execution

Inventory Management

Effective inventory management is crucial in Supply Chain Execution. You need to balance supply and demand to avoid excess inventory or stockouts.

Techniques and Tools

- Just-in-Time (JIT) Inventory: This technique minimizes inventory levels by receiving goods only as needed for production. It reduces storage costs and waste.

- ABC Analysis: Categorize inventory into three classes (A, B, C) based on importance. Focus more on A items, which are high-value products.

- Inventory Control Tools: Use software to track inventory levels, orders, and deliveries. These tools help you achieve a leaner inventory model, saving money.

Challenges and Solutions

Managing inventory comes with challenges like the bullwhip effect, where small changes in demand cause large fluctuations in supply. To tackle this:

- Incorporate Supply Chain Planning Inputs: Align supply with demand forecasts to prevent excess inventory and stockouts.

- Case Study: A company faced high storage costs due to overstocking. By implementing JIT and using inventory control tools, they achieved a leaner model and reduced costs.

Order Fulfillment

Order fulfillment is another vital part of Supply Chain Execution. It ensures that customers receive their products on time.

Process Overview

- Order Processing: Capture and confirm customer orders.

- Picking and Packing: Select and package the products for shipment.

- Shipping: Deliver the products to the customer’s location.

Best Practices

- Automate Processes: Use technology to streamline order processing and reduce errors.

- Optimize Warehouse Layout: Arrange products efficiently to speed up picking and packing.

- Monitor Performance: Track key metrics like delivery times and accuracy to improve service levels.

By focusing on these core elements, you enhance your Supply Chain Execution, leading to cost savings and improved customer satisfaction.

Types of Supply Chain Execution Software

In the realm of Supply Chain Execution, software plays a pivotal role in streamlining operations. Two primary types of software systems are essential: Warehouse Management Systems (WMS) and Transportation Management Systems (TMS). These tools help you manage and optimize the flow of goods efficiently.

Warehouse Management Systems (WMS)

Warehouse Management Systems are crucial for managing warehouse operations. They ensure that your inventory is stored, tracked, and moved efficiently.

Features and Benefits

- Space Allocation: WMS software helps you allocate space effectively, ensuring optimal use of your warehouse.

- Resource Management: It automates the allocation of human resources, enhancing productivity.

- Real-time Information: Instantly relay information to colleagues, improving communication and decision-making.

- Special Services: Manage packaging, white-labeling, and backorder processing to enhance customer satisfaction.

These features lead to better organization and efficiency within your warehouse, ultimately improving your Supply Chain Execution.

Implementation Considerations

When implementing a WMS, consider the following:

- Integration: Ensure it integrates seamlessly with existing systems.

- Scalability: Choose a system that can grow with your business needs.

- User Training: Provide adequate training to staff for smooth adoption.

A well-implemented WMS can transform your warehouse operations, making them more efficient and responsive.

Transportation Management Systems (TMS)

Transportation Management Systems focus on optimizing the movement of goods from one location to another. They are vital for effective Supply Chain Execution.

Key Functions

- Route Optimization: TMS software helps you plan the most efficient routes, reducing transportation costs.

- Freight Tracking: Monitor shipments in real-time, ensuring timely deliveries.

- Document Management: Handle all necessary documentation digitally, streamlining processes.

These functions enhance your ability to manage transportation logistics effectively.

Integration with Other Systems

Integrating TMS with other systems, such as WMS, offers several advantages:

- Improved Scheduling: Optimize the scheduling of trucks, drivers, and warehouse staff.

- Enhanced Visibility: Gain better insight into warehouse and transportation processes.

- Reduced Manual Entry: Minimize errors by automating data sharing between systems.

By integrating TMS and WMS, you create a cohesive system that enhances overall Supply Chain Execution. This integration leads to faster delivery windows and reduced costs, providing a competitive edge.

Benefits of Effective Supply Chain Execution

Effective Supply Chain Execution offers numerous advantages that can transform your business operations. By focusing on key areas, you can achieve significant improvements in both cost efficiency and customer satisfaction.

Cost Reduction

Supply Chain Execution plays a vital role in reducing costs. Here’s how you can leverage it:

Strategies for Efficiency

- Optimize Resource Utilization: Use advanced solutions to manage resources effectively. This reduces labor requirements and lowers error rates.

- Implement Data-Driven Systems: Utilize data and proper management systems to streamline operations. This approach cuts unnecessary expenses and enhances overall efficiency.

- Enhance Logistics Operations: Focus on optimizing dock scheduling and yard control. These improvements lead to substantial cost savings.

By adopting these strategies, you can minimize waste and maximize productivity.

Case Studies

Consider companies that have successfully implemented these strategies:

- JDA Manufacturing Planning: This software increased production efficiency and reduced inventory levels. The result was a notable decrease in operational costs.

- C3 Solutions: By optimizing logistics operations, they achieved significant cost reductions. Their approach also boosted customer satisfaction.

These examples illustrate how effective Supply Chain Execution can lead to financial benefits.

Enhanced Customer Satisfaction

Improving Supply Chain Execution not only reduces costs but also enhances customer satisfaction. Here’s how it impacts service levels:

Impact on Service Levels

- Timely Deliveries: Efficient execution ensures products reach customers on time. This reliability builds trust and loyalty.

- Accurate Order Fulfillment: By minimizing errors, you enhance the accuracy of deliveries. Customers appreciate receiving the correct products promptly.

- Improved Communication: Real-time information sharing keeps customers informed. This transparency enhances their experience.

These factors contribute to a positive customer relationship, driving repeat business.

Real-world Examples

- Companies Utilizing Data: Businesses that use data-driven systems see improvements in customer satisfaction. They achieve this by aligning supply with demand more effectively.

- Advanced Solutions: Firms implementing advanced solutions report higher customer satisfaction. These tools optimize logistics, ensuring smooth and efficient operations.

By focusing on these elements, you can elevate your service levels and foster customer loyalty.

Challenges in Supply Chain Execution

Navigating Supply Chain Execution presents several challenges that can impact your business operations. Understanding these obstacles helps you develop strategies to overcome them.

Common Obstacles

Supply Chain Disruptions

Supply chain disruptions can significantly affect your operations. Factors like supply restrictions, labor shortages, and unexpected demand fluctuations create hurdles. According to the McKinsey Global Institute, these disruptions have historically led to substantial financial losses. Modern customers expect transparency and adaptability in supply chains. You must be prepared to address these expectations to maintain trust and efficiency.

Managing Complexity

Managing the complexity of Supply Chain Execution involves coordinating multiple components. From procurement to delivery, each step requires precise management. The intricate nature of these processes can lead to inefficiencies if not handled properly. You need to streamline operations to ensure smooth execution.

Overcoming Challenges

Innovative Solutions

To tackle these challenges, you can adopt innovative solutions. Kristin Smith, President of Fernish, highlights the importance of evolving collaboration with partners. By adding alternative products and adjusting sourcing plans, you can enhance flexibility. Offering backordered products and improving customer interaction also contribute to a more resilient supply chain.

Industry Trends

Staying informed about industry trends is crucial. Companies that leverage data and local suppliers often see improved profits and customer satisfaction. Embracing technology and modern management systems can help you stay ahead. These tools enable you to optimize resources and respond swiftly to changes.

By understanding and addressing these challenges, you can enhance your Supply Chain Execution. This approach not only improves efficiency but also strengthens customer relationships.

Practical Tips for Improving Supply Chain Execution

Enhancing your Supply Chain Execution can significantly boost your business efficiency and customer satisfaction. Here are some practical tips to help you achieve this.

Leveraging Technology

Technology plays a pivotal role in optimizing Supply Chain Execution. By adopting the right tools, you can streamline operations and improve decision-making.

Automation and AI

- Implement Automation: Automation reduces manual tasks, minimizing errors and increasing efficiency. Automated systems handle repetitive tasks like order processing and inventory management, freeing up your workforce for more strategic activities.

- Utilize AI for Predictive Analytics: AI provides insights into demand forecasting and inventory optimization. By analyzing historical data, AI predicts future trends, helping you make informed decisions. This proactive approach reduces stockouts and overstock situations.

"Adopting real-time technologies like advanced analytics and AI to automate supply chain risk management is crucial. It also promotes greater resilience, transparency, and the capacity to act swiftly and cooperatively."

Data Analytics

- Leverage Data for Insights: Data analytics offers a comprehensive view of your supply chain. By analyzing data from various sources, you identify bottlenecks and areas for improvement. This insight allows you to optimize processes and enhance efficiency.

- Monitor Key Performance Indicators (KPIs): Track KPIs such as delivery times, order accuracy, and inventory turnover. Regular monitoring helps you assess performance and make necessary adjustments to improve Supply Chain Execution.

Collaboration and Communication

Effective collaboration and communication are essential for seamless Supply Chain Execution. Building strong relationships with partners and maintaining clear communication channels can lead to better outcomes.

Building Strong Partnerships

- Foster Collaborative Relationships: Work closely with suppliers, manufacturers, and logistics providers. Strong partnerships ensure smooth operations and timely deliveries. Regular meetings and open communication foster trust and cooperation.

- Engage in Joint Planning: Collaborate with partners on demand forecasting and inventory planning. Joint efforts lead to more accurate predictions and efficient resource allocation, enhancing overall Supply Chain Execution.

Effective Communication Strategies

- Establish Clear Communication Channels: Use technology to facilitate communication across the supply chain. Tools like instant messaging and video conferencing enable real-time information sharing, reducing delays and misunderstandings.

- Provide Regular Updates: Keep all stakeholders informed about changes and developments. Regular updates ensure everyone is aligned and working towards common goals, improving coordination and execution.

By implementing these practical tips, you can unlock the full potential of your Supply Chain Execution process. This not only enhances operational efficiency but also delivers exceptional customer experiences. Mastering Supply Chain Execution is critical for staying ahead in today's competitive business environment.

Future of Supply Chain Execution

Emerging Trends of Supply Chain Execution

Sustainability Initiatives

Sustainability is becoming a cornerstone of modern supply chain execution. You can see companies increasingly adopting eco-friendly practices to minimize their environmental impact. This shift is not just about reducing carbon footprints; it also involves using sustainable materials and optimizing logistics to cut down on emissions. By integrating sustainability into your supply chain, you not only contribute to environmental conservation but also enhance your brand's reputation. Customers today prefer businesses that prioritize sustainability, making it a crucial aspect of future supply chain strategies.

Digital Transformation

Digital transformation is reshaping how supply chains operate. Technologies like machine learning, blockchain, and augmented reality are revolutionizing traditional processes. You can leverage these tools to enhance efficiency, visibility, and responsiveness in your supply chain. For instance, blockchain ensures transparency and traceability, while machine learning optimizes inventory management by predicting demand patterns. By embracing digital transformation, you position your business to meet the evolving demands of the global marketplace.

"Technological advances are catalyzing the digitalization of supply chain management, changing how products and services are made and delivered." - BSR

Predictions and Insights

Expert Opinions

Experts predict that the future of supply chain execution will be heavily influenced by technology and sustainability. They emphasize the need for businesses to adopt higher-value strategies that cater to the needs of customers, employees, and society. By focusing on digital transformation and sustainability, you can maintain a competitive edge in the rapidly evolving market.

"Global supply chain leaders must adopt higher-value supply chain strategies to meet the needs of customers, employees, shareholders, and society." - Tredence

Long-term Implications

The long-term implications of these trends are profound. As you integrate advanced technologies and sustainable practices, your supply chain becomes more resilient and adaptable. This adaptability is crucial in navigating the complexities of the global market. Moreover, by prioritizing sustainability, you align your business with the growing consumer demand for environmentally responsible practices. These changes not only enhance operational efficiency but also ensure long-term success and growth.

By staying informed about these emerging trends and predictions, you can effectively prepare for the future of supply chain execution. This proactive approach ensures that your business remains competitive and responsive to the ever-changing market dynamics.

Supply chain execution plays a pivotal role in enhancing operational efficiency and customer satisfaction. By focusing on effective execution strategies, you can reduce costs and improve service delivery. A well-optimized supply chain allows your business to adapt swiftly to market changes, ensuring agility and flexibility. As the landscape continues to evolve, embracing new technologies and sustainable practices will unlock future potential. Prioritizing supply chain execution not only strengthens your operations but also positions your business for long-term success.

FAQ

Supply Chain Execution involves managing the flow of goods from procurement to delivery. You focus on the practical implementation of supply chain activities, ensuring products reach customers efficiently.

Supply Chain Management focuses on planning and strategy. In contrast, Supply Chain Execution emphasizes action. You put plans into practice, handling day-to-day operations to keep the supply chain moving smoothly.

Effective Supply Chain Execution enhances customer satisfaction by ensuring timely and accurate deliveries. It also reduces costs, making it a critical area for business success.

Procurement: Acquiring raw materials or products.

Production: Transforming materials into finished goods.

Warehousing: Storing products until needed.

Transportation: Moving goods to their final destination.

Technology streamlines operations through automation and data analytics. You can use tools like Warehouse Management Systems (WMS) and Transportation Management Systems (TMS) to optimize inventory and logistics.

Common challenges include supply chain disruptions and managing complexity. You need to address these by adopting innovative solutions and staying informed about industry trends.

Dealing with stockouts requires effective inventory management. Techniques like Just-in-Time (JIT) inventory and data-driven forecasting help you align supply with demand.

Key skills include problem-solving, communication, and analytical thinking. You should also have knowledge of supply chain technologies and strategies to add value to your team.

Continue Reading About Supply Chain Execution

Augmented Analytics: Unlock the Core Concepts & Benefits!

Discover augmented analytics—where AI and ML automate data prep and insights, revolutionizing decision-making for smarter, faster business strategies!

Lewis

Mar 04, 2025

Essential Guide to Supplier Data Management Best Practices

Master supplier data management with best practices to enhance relationships, boost efficiency, and secure data using advanced tools like FineDataLink.

Howard

Nov 04, 2024

Empower Your Business: Best Financial Reporting Tools 2025

Discover the best financial reporting tools in 2025 for streamlined processes and accurate insights. Empower your business with advanced solutions!

Lewis

Jun 15, 2024

Data Analysis vs Data Analytics: What’s the Real Difference?

Data Analysis vs Data Analytics: What’s the Difference? Discover How One Interprets History While the Other Shapes Tomorrow. Explore Here!

Lewis

Mar 10, 2025

Best Data Integration Vendors for Seamless Workflows

Discover the top 20 data integration vendors of 2025 for seamless workflows. Compare tools like Talend, AWS Glue, and Fivetran to optimize your data processes.

Howard

Jan 22, 2025

How Data Management Consultants Boost Operational Efficiency

Boost operational efficiency with data management consultants. Enhance decision-making, streamline processes, and achieve cost savings with expert strategies.

Howard

Nov 29, 2024