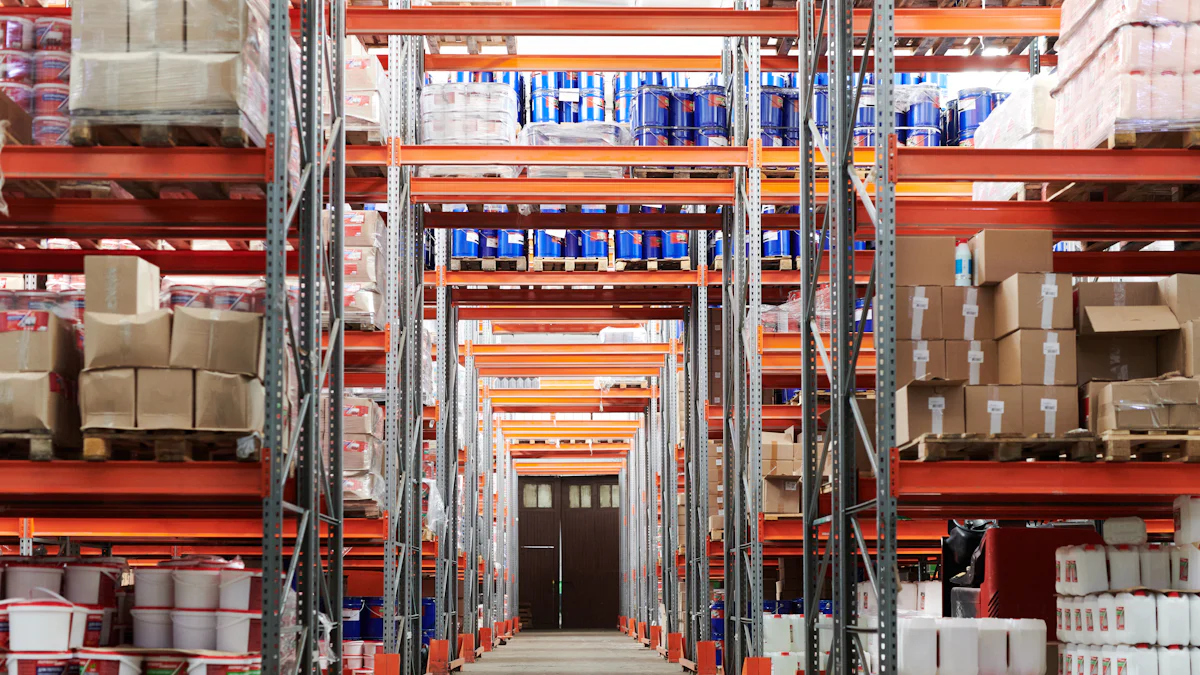

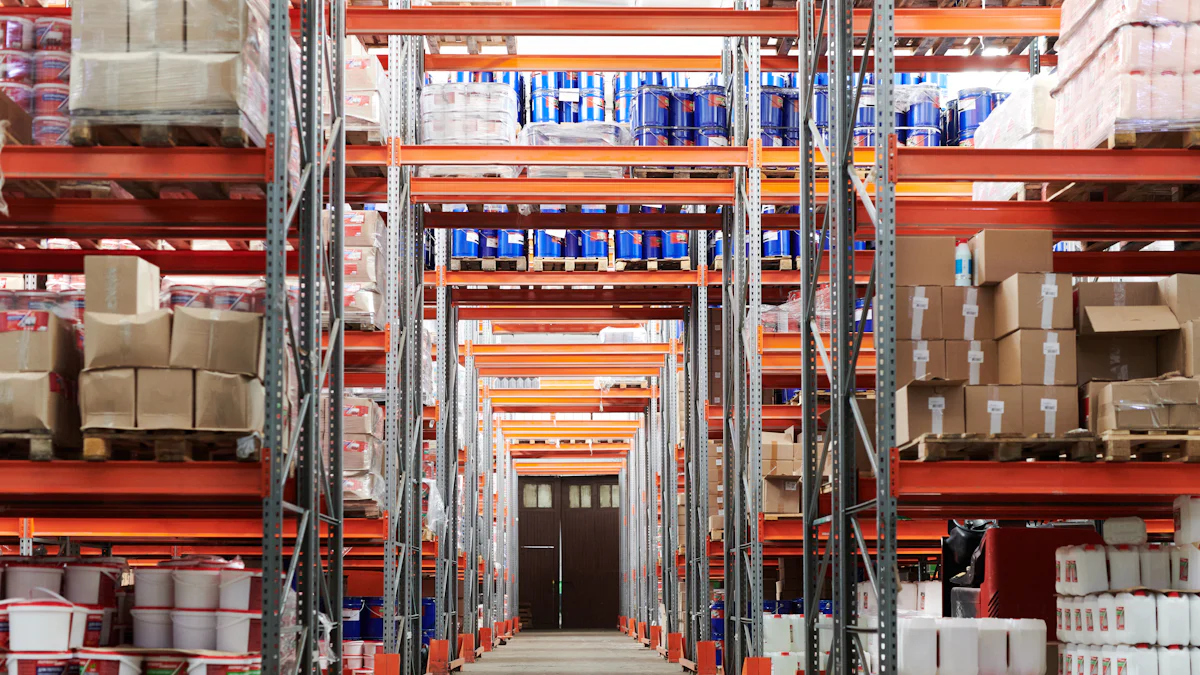

Warehouse operations involve activities like receiving, storing, picking, packing, and shipping products. These operations play a crucial role in the supply chain by ensuring efficient inventory management. Effective warehouse operations prevent stockouts and reduce supply chain disruptions. Automated storage systems enhance efficiency by optimizing space and reducing accidents. Understanding these operations is vital for improving business growth and customer satisfaction.

Understanding Warehouse Operations

Definition and Scope of Warehouse Operations

Warehouse operations encompass a range of activities essential for managing inventory efficiently. These activities ensure that goods move seamlessly through the supply chain.

Key Functions

Warehouse operations perform several key functions:

-

Receiving: Accepting goods from suppliers.

-

Storing: Organizing products in designated areas.

-

Picking: Selecting items for customer orders.

-

Packing: Preparing goods for shipment.

-

Shipping: Dispatching products to customers.

Each function contributes to the overall efficiency of the warehouse.

Core Activities

Core activities in warehouse operations include:

-

Inventory Management: Monitoring stock levels to prevent shortages.

-

Quality Control: Inspecting goods for damage or defects.

-

Order Processing: Managing customer orders from receipt to delivery.

These activities ensure accuracy and timeliness in fulfilling customer demands.

Historical Context of Warehouse Operations

Warehouse operations have evolved significantly over time, adapting to changes in technology and business needs.

Evolution Over Time

Warehouses have existed since ancient times. Early warehouses stored surplus goods for trade. The Industrial Revolution brought significant changes. Factories required efficient storage solutions. Modern warehouses now use advanced systems to manage inventory.

Technological Advancements

Technological advancements have transformed warehouse operations. Automated systems streamline processes. Robotics enhance picking and packing efficiency. Technology reduces human error and increases productivity.

"Technology is best when it brings people together." — Matt Mullenweg

Understanding these historical contexts helps in appreciating the current state of warehouse operations.

Key Components of Warehouse Operations

Warehouse operations consist of several key components that ensure the smooth functioning of a warehouse. These components include inventory management and order fulfillment, each playing a critical role in maintaining efficiency and accuracy.

Inventory Management

Inventory management is a fundamental aspect of warehouse operations. It involves overseeing and controlling stock levels to meet customer demands without overstocking or understocking.

Stock Control

Stock control ensures that the right amount of inventory is available at all times. Warehouse operations use various techniques to manage stock effectively. Public warehouses often employ a warehouse management system (WMS) for this purpose. This system provides real-time data on inventory levels, helping to prevent shortages or excesses. Private warehouses, on the other hand, may use an inventory management system tailored to their specific needs. Both systems aim to optimize stock levels and reduce holding costs.

Demand Forecasting

Demand forecasting predicts future customer demand to maintain optimal inventory levels. Accurate forecasting is crucial in warehouse operations. It helps in planning stock replenishments and avoiding stockouts. Techniques such as trend analysis and historical data evaluation assist in making informed predictions. Effective demand forecasting leads to improved customer satisfaction and reduced operational costs.

Order Fulfillment

Order fulfillment is another vital component of warehouse operations. It encompasses the entire process from receiving customer orders to delivering products.

Picking and Packing

Picking involves selecting the correct items from storage to fulfill customer orders. Efficient picking processes are essential in warehouse operations to minimize errors and speed up order processing. Packing follows picking, where items are securely packaged for shipment. Proper packing ensures that products reach customers in good condition, enhancing customer satisfaction.

Shipping Processes

Shipping processes involve dispatching packed goods to customers. Warehouse operations must ensure timely and accurate shipments. This involves coordinating with carriers, preparing shipping documents, and tracking deliveries. Efficient shipping processes contribute to overall customer satisfaction and business success.

Warehouse operations rely on these key components to function effectively. Each component plays a distinct role in ensuring that goods move efficiently through the supply chain. By focusing on inventory management and order fulfillment, warehouse operations can achieve high levels of efficiency and accuracy.

Types of Warehouse Operations

Warehouse operations can be categorized into different types based on ownership and management. Understanding these types helps businesses choose the most suitable option for their needs.

Public Warehousing

Public warehousing involves facilities owned by third parties. These warehouses provide storage and related services to multiple clients.

Advantages

Public warehouses offer several advantages:

-

Flexibility: Companies can adjust space usage according to demand fluctuations.

-

Cost-Effectiveness: Businesses avoid the high costs of owning and maintaining a warehouse.

-

Expertise: Professional management ensures efficient warehouse operations.

Public warehousing suits companies with variable storage needs or limited resources.

Disadvantages

Public warehousing also has some disadvantages:

-

Limited Control: Companies may have less control over warehouse operations and processes.

-

Potential Delays: Shared facilities might lead to scheduling conflicts and delays.

-

Customization Limitations: Specific requirements may not be easily accommodated.

Businesses must weigh these factors when considering public warehousing.

Private Warehousing

Private warehousing refers to facilities owned and operated by a single company. This type of warehouse serves the specific needs of the owner.

Benefits

Private warehousing provides several benefits:

-

Complete Control: Companies have full control over warehouse operations and customization.

-

Tailored Solutions: Facilities can be designed to meet specific business needs.

-

Branding Opportunities: Warehouses can reflect the company's brand and values.

Private warehousing is ideal for businesses with stable demand and specific operational requirements.

Limitations

Private warehousing also presents limitations:

-

High Costs: Ownership involves significant investment in construction and maintenance.

-

Inflexibility: Adapting to changes in demand can be challenging.

-

Resource Intensive: Managing warehouse operations requires dedicated resources and expertise.

Companies must evaluate these aspects when opting for private warehousing.

Case Study: When to Opt for Private or Public Warehousing

A study analyzed the choice between public and private warehouses. The study highlighted that public warehousing benefits smaller companies with fluctuating storage needs. Private warehousing suits larger businesses with stable demand and specific operational needs. This comparison helps companies determine the best option based on size, nature of business, and available resources.

Processes Involved in Warehouse Operations

Warehouse operations encompass various processes that ensure the efficient handling of goods. Each process plays a vital role in maintaining the flow of inventory and optimizing warehouse efficiency.

Receiving Goods

Receiving goods is a critical step in warehouse operations. This process involves several key activities to ensure accuracy and quality.

Inspection

Inspection ensures that received goods meet quality standards. Warehouse staff check for damages and verify quantities. Accurate inspection prevents future discrepancies and maintains customer satisfaction.

Documentation

Documentation records all received items. Warehouse operations rely on accurate records to track inventory levels. Proper documentation supports inventory management and order fulfillment processes.

Storage Solutions

Storage solutions are essential for effective warehouse operations. These solutions maximize space utilization and enhance accessibility.

Racking Systems

Racking systems organize products within the warehouse. Different types of racks accommodate various product sizes and weights. Proper racking enhances retrieval efficiency and reduces handling time.

Space Optimization

Space optimization involves strategic placement of goods. Efficient use of space increases storage capacity. Automated systems contribute to space optimization by reducing accidents and improving accessibility.

"Warehouse storage solutions are essential for the supply chain process." — Meteorspace, 2024

Warehouse operations benefit from well-planned storage solutions. Selecting the right system ensures cost-effectiveness and operational success.

Importance of Efficient Warehouse Operations

Efficient warehouse operations hold significant importance in the logistics and supply chain industry. These operations contribute to cost reduction and enhance customer satisfaction. Businesses must focus on optimizing warehouse operations to achieve these benefits.

Cost Reduction

Warehouse operations play a crucial role in reducing costs. Effective management of resources and processes leads to significant savings for businesses.

Minimizing Waste

Minimizing waste stands as a primary objective in warehouse operations. Proper inventory management reduces excess stock and prevents spoilage. Efficient storage solutions decrease damage to goods. Streamlined processes ensure that resources are used optimally. Businesses benefit from reduced operational costs through waste minimization.

Streamlining Processes

Streamlining processes enhances the efficiency of warehouse operations. Automation and technology improve workflow and reduce manual labor. Efficient picking and packing systems speed up order fulfillment. Warehouse operations become more productive with streamlined processes. Cost savings result from increased efficiency and reduced labor expenses.

Customer Satisfaction

Customer satisfaction is a key outcome of efficient warehouse operations. Timely deliveries and accurate orders contribute to positive customer experiences.

Timely Deliveries

Timely deliveries are essential for maintaining customer satisfaction. Efficient warehouse operations ensure that products reach customers on schedule. Proper coordination of shipping processes prevents delays. Businesses gain a competitive edge by meeting delivery deadlines consistently. Timely deliveries enhance customer loyalty and trust.

Accurate Orders

Accurate orders are vital for customer satisfaction in warehouse operations. Proper picking and packing processes ensure that customers receive the correct items. Quality control measures prevent errors in order fulfillment. Businesses build a reputation for reliability through accurate orders. Customer satisfaction increases when expectations are met consistently.

Warehouse operations significantly impact cost reduction and customer satisfaction. Businesses must prioritize efficiency in these operations to achieve success. Proper management of resources and processes leads to improved outcomes in the supply chain.

Challenges in Warehouse Operations

Warehouse operations face numerous challenges that impact efficiency and productivity. These challenges require strategic solutions to ensure smooth functioning.

Labor Shortages

Labor shortages present a significant challenge in warehouse operations. The demand for efficient order fulfillment increases, yet the workforce remains insufficient.

Impact on Efficiency

Labor shortages directly affect the efficiency of warehouse operations. Insufficient staff leads to delays in receiving, picking, and shipping processes. Reduced manpower results in slower order processing times. Warehouses struggle to meet customer demands promptly. This inefficiency impacts overall business performance and customer satisfaction.

Solutions and Strategies

Solutions exist to address labor shortages in warehouse operations. Automation offers a viable option to reduce dependency on human labor. Automated systems enhance picking and packing processes. Robotics improve accuracy and speed in warehouse tasks. Cross-training employees increases workforce flexibility. Staff can perform multiple roles, reducing the impact of absences. Competitive wages and benefits attract and retain skilled workers. Improved working conditions enhance employee satisfaction and retention.

"The labor shortage is a harsh reality impacting businesses across industries." — Unknown, Warehouse Management Expert

Technological Integration

Technological integration poses challenges in warehouse operations. Implementing new technologies requires careful planning and execution.

Implementation Barriers

Several barriers hinder the implementation of technology in warehouse operations. High initial costs deter investment in advanced systems. Complex integration processes require technical expertise. Resistance to change exists among employees accustomed to traditional methods. Training staff on new technologies demands time and resources. Compatibility issues arise with existing systems and infrastructure.

Overcoming Challenges

Overcoming technological integration challenges involves strategic approaches. Gradual implementation allows for smoother transitions. Pilot programs test new technologies before full-scale adoption. Training programs equip employees with necessary skills. Collaboration with technology providers ensures seamless integration. Regular maintenance and updates enhance system performance.

"Learn how to optimize your warehouse processes in order to operate more efficiently." — Unknown, Warehouse Management Expert

Warehouse operations must address these challenges to maintain efficiency. Labor shortages and technological integration require proactive solutions. By implementing strategic measures, warehouses can overcome obstacles and achieve operational success.

Future Trends in Warehouse Operations

Automation and Robotics

Emerging Technologies

Automation and robotics are transforming warehouse operations. New technologies include automated guided vehicles (AGVs) and robotic arms. These innovations enhance efficiency by performing repetitive tasks. Automated systems connect with warehouse management systems for real-time tracking. This integration provides insights into inventory levels and product flow.

Benefits and Drawbacks

Automation reduces labor dependency and increases accuracy. Robots handle tasks like picking and packing, minimizing errors. Automated systems improve speed in order fulfillment. However, high initial costs can deter investment. Training staff to operate new technologies requires time and resources. Some employees may resist changes due to unfamiliarity with technology.

Sustainability Practices

Eco-friendly Solutions

Sustainability practices focus on reducing environmental impact. Warehouses adopt eco-friendly solutions such as energy-efficient lighting. Solar panels provide renewable energy sources. Green packaging materials reduce waste and pollution. Sustainable practices align with global efforts to combat climate change.

Long-term Impact

Eco-friendly solutions offer long-term benefits. Reduced energy consumption lowers operational costs. Sustainable practices enhance brand reputation and customer trust. Companies contribute to environmental conservation. Long-term sustainability leads to a healthier planet and improved business outcomes.

The Interconnected Nature of Warehouse Operations

How Each Activity Affects Overall Performance

Warehouse operations consist of interconnected activities. Each activity impacts the overall performance of the warehouse. Efficient execution of these activities ensures smooth operations and optimal productivity.

Receiving to Shipping

Receiving initiates the warehouse process. Accurate receiving prevents errors in inventory management. Inspection and documentation ensure quality and quantity. Proper receiving sets the stage for subsequent activities.

Storage follows receiving. Effective storage solutions maximize space utilization. Racking systems organize products for easy retrieval. Space optimization enhances accessibility and reduces handling time.

Picking and packing prepare orders for shipment. Accurate picking minimizes errors in order fulfillment. Efficient packing ensures product safety during transit. These activities maintain customer satisfaction through timely deliveries.

Shipping concludes the warehouse process. Timely shipping ensures products reach customers on schedule. Coordination with carriers prevents delays. Accurate shipping maintains customer trust and loyalty.

"Warehouse storage solutions are essential for the supply chain process." — Meteorspace, 2024

Impact on Supply Chain Efficiency

Warehouse operations directly affect supply chain efficiency. Efficient operations reduce lead times and improve service levels. Proper inventory management prevents stockouts and excesses. Streamlined processes enhance order accuracy and speed.

Automation plays a crucial role in enhancing efficiency. Automated systems reduce labor dependency and increase accuracy. Robotics perform repetitive tasks, minimizing errors. Technology integration provides real-time insights into inventory levels.

Labor shortages pose challenges to efficiency. Automation mitigates the impact of labor shortages. Cross-training employees increases workforce flexibility. Competitive wages attract and retain skilled workers.

Selecting the right warehouse storage system optimizes inventory movement. Efficient storage reduces operational costs and enhances productivity. Well-planned warehouse operations contribute to overall supply chain success.

Warehouse operations hold significant importance in ensuring efficient inventory management and customer satisfaction. Continuous improvement remains essential for addressing challenges like labor shortages. Businesses must focus on optimizing processes to retain top talent and reduce turnover. Adapting to future trends, such as automation and sustainability, will enhance operational success. Embracing these advancements ensures warehouses meet evolving demands and maintain a competitive edge in the logistics industry.

FAQ

Warehouse operations include receiving, storing, picking, packing, and shipping products. These activities ensure efficient inventory management and order fulfillment.

Inventory management prevents stockouts and reduces supply chain disruptions. Proper management ensures that goods are available when needed, enhancing customer satisfaction.

Labor shortages lead to delays in receiving, picking, and shipping processes. Insufficient staff affects efficiency and can reduce overall productivity.

Automation and robotics help manage labor shortages by reducing dependency on human labor. Cross-training employees increases flexibility, while competitive wages attract skilled workers.

Technology streamlines processes and reduces human error. Automated systems and robotics improve efficiency in picking and packing tasks.

Public warehousing offers flexibility and cost-effectiveness. Companies can adjust space usage according to demand and avoid high ownership costs.

High initial costs and complex integration processes pose challenges. Training staff and ensuring compatibility with existing systems require careful planning.

Sustainable practices reduce environmental impact and operational costs. Eco-friendly solutions enhance brand reputation and contribute to long-term success.

Continue Reading About Warehouse Operations

2025 Best Data Integration Solutions and Selection Guide

Explore top data integration solutions for 2025, enhancing data management and operational efficiency with leading platforms like Fivetran and Talend.

Howard

Dec 19, 2024

10 Game-Changing Project Management Reporting Types!

Unlock project success with 10 must-know reporting types! Track progress, manage risks, and stay on budget like a pro.

Lewis

Mar 03, 2025

Which Data Analysis Projects Work Best for Beginners?

Ready to shine in 2025? Discover easy data analysis projects to boost your portfolio, learn data cleaning, visualization, and tackle real-world challenges!

Lewis

Mar 10, 2025

50+ Must-Have Business Tools for Small Businesses to Succeed in 2025

Discover 50+ essential business tools for small businesses in 2025. Boost productivity, streamline operations, and achieve success with the right tools.

Lewis

Mar 13, 2025

Business Data Analyst vs Business Analyst Key Differences Explained

Compare business data analyst vs business analyst roles, focusing on key differences, responsibilities, skills, and career paths to guide your career choice.

Lewis

Mar 11, 2025

Creating an Excel Dashboard: Easy Steps for Beginners

Learn to create Excel dashboards with templates for easy data visualization and analysis. Perfect for beginners seeking efficient insights.

Lewis

Nov 05, 2024