Product Lifecycle Management

Sean, Industry Editor

Apr 25, 2025

Product Lifecycle Management (PLM) is a strategic approach that helps you oversee every phase of a product's journey, from its initial idea to its eventual retirement. This method ensures smooth coordination across design, development, production, and disposal, creating a unified process.

Companies adopting PLM systems often experience remarkable improvements. For instance:

- Integrated PLM systems can boost product quality and speed to market by up to 30%.

- The PLM market is projected to grow from USD 34.17 billion in 2024 to USD 77.67 billion by 2035, reflecting its increasing value.

By optimizing workflows, PLM empowers you to enhance product quality and significantly reduce production delays.

Key Takeaways

- Product Lifecycle Management (PLM) helps manage a product's stages better.

- Using PLM can make products reach the market 30% faster.

- PLM keeps all data in one place, improving quality and rules.

- It helps teams work together, reducing mistakes and delays.

- Tools like FineDataLink make PLM smoother with real-time updates.

Understanding Product Lifecycle Management

Definition and Purpose of PLM

Product lifecycle management (PLM) serves as a comprehensive framework to oversee a product's journey from its initial concept to its retirement. It ensures that every stage of the lifecycle is managed efficiently, enabling you to streamline processes and make informed decisions. By adopting PLM, you can align your strategies with the product's lifecycle stage, whether it involves innovation during development or optimization during maturity. PLM software plays a pivotal role in this process. It helps you manage data, track progress, and ensure collaboration across teams.

Key Stages of the Product Lifecycle

Understanding the key stages of a product's lifecycle is essential for effective management. Each stage presents unique challenges and opportunities that require specific strategies. The lifecycle typically includes the following stages:

- Concept and Development: This stage involves brainstorming ideas, conducting market research, and creating prototypes. It sets the foundation for the product's success.

- Introduction: Here, you launch the product into the market. Marketing efforts and customer feedback play a crucial role in shaping its trajectory.

- Growth: During this phase, the product gains traction, and demand increases. You focus on scaling production and optimizing processes.

- Maturity: At this stage, the product reaches peak market penetration. Strategies shift towards maintaining market share and managing competition.

- Decline: Eventually, the product's demand decreases. You may decide to phase it out or innovate to extend its lifecycle.

These stages align with the data lifecycle, which includes data generation, collection, processing, storage, management, analysis, visualization, and interpretation. By understanding these phases, you can streamline processes, gain insights into customer behavior, and enhance product quality.

Why PLM is Crucial for Modern Businesses

In today's competitive landscape, PLM has become indispensable for businesses aiming to stay ahead. It offers several benefits that directly impact your organization's efficiency and profitability. For instance, PLM software can:

- Reduce cycle time from concept to delivery, enhancing efficiency in product development.

- Streamline process tracking and approvals, minimizing delays and improving workflow.

- Save costs by referring to historical product lifecycles, eliminating redundant activities.

- Link design activities to manufacturing and ERP systems, improving visibility and coordination.

- Monitor corrective actions for each item, ensuring quality control and accountability.

These features not only improve operational efficiency but also help you adapt to market changes swiftly. Research shows that businesses using PLM software experience a 25% uplift in win rates, a 25% reduction in time to market, and a 15% increase in key metrics for novice manufacturers.

Core Components of Product Lifecycle Management

Product Data Management (PDM)

Product Data Management (PDM) is the backbone of product lifecycle management. It focuses on organizing, storing, and managing product-information throughout the product lifecycle. By centralizing data, PDM ensures that all stakeholders have access to accurate and up-to-date information, reducing errors and improving decision-making.

PDM systems enhance data accuracy and operational efficiency. For example, studies show that implementing PDM can lead to significant improvements:

By leveraging PDM, you can streamline product lifecycle processes, ensuring that product-information is consistent and accessible across teams. This not only improves collaboration but also reduces the time spent searching for data, allowing you to focus on innovation and efficiency.

Product Design and Development

The product design and development phase is where ideas transform into tangible products. This stage involves creating prototypes, testing designs, and refining features to meet customer needs. A robust product development process ensures that your product aligns with market demands while maintaining high quality.

PLM systems play a crucial role in enhancing this phase. They enable seamless data sharing, co-engineering, and networking, which significantly reduce the time to market. Here are some key benefits of integrating PLM into the product design and development process:

| Benefit | Description | | --- | --- | | Reduction of time to market | Data sharing, co-engineering, and networking significantly decrease the time required to bring a product to market. | | Increase in quality | Adhering to standards and sharing information ensures that all design stages are properly followed, enhancing product quality. | | Cost reduction | PLM integration allows for early detection of design issues, minimizing wasted time and reducing costs through real-time data access. | | Management optimization | Effective information sharing and structured processes lead to improved project management and reporting. | | Acceleration of innovation | PLM facilitates controlled innovation by formalizing customer requirements and integrating digital simulations, aligning product launches with market needs. |

By adopting PLM tools, you can optimize the product development process, ensuring that your product meets customer expectations while minimizing costs and delays.

Supply Chain Collaboration

Supply chain collaboration is a critical component of product lifecycle management. It ensures that all stakeholders, including suppliers, manufacturers, and customers, work together seamlessly. PLM software acts as a centralized hub for product-information, enhancing visibility and communication across the supply chain.

With PLM, you can reduce miscommunication and errors caused by disconnected systems. Real-time communication allows suppliers to contribute during the design phase, manufacturers to adjust production schedules based on demand, and customers to provide feedback that shapes product development. This collaborative approach not only improves efficiency but also ensures that your product aligns with market needs.

For example, integrating PLM into supply chain collaboration enables you to:

- Share product-information with stakeholders in real-time.

- Adjust production schedules dynamically to meet changing demands.

- Incorporate customer feedback into the product development process.

By fostering collaboration, PLM helps you build a more agile and responsive supply chain, ensuring that your product reaches the market faster and with higher quality.

Product Testing and Quality Assurance

Product testing and quality assurance are essential steps in the product lifecycle. These processes ensure that your product meets the required standards and satisfies customer expectations. By identifying potential issues early, you can avoid costly recalls and maintain your brand's reputation.

Testing involves evaluating the product's performance, durability, and safety. For example, you might conduct stress tests to determine how well the product withstands extreme conditions. Quality assurance, on the other hand, focuses on maintaining consistent standards throughout the lifecycle. This includes monitoring production processes and verifying that each unit meets the desired specifications.

PLM tools play a significant role in streamlining these activities. They facilitate automatic quality checks at various stages, ensuring that your product adheres to industry-specific safety standards and environmental regulations. This reduces the risk of non-compliance and enhances customer trust. Additionally, PLM systems allow you to document testing results and quality metrics, making it easier to address compliance inquiries from regulators.

To maximize the effectiveness of testing and quality assurance, you should establish clear performance indicators. These metrics help you measure the success of your efforts and identify areas for improvement. For instance, tracking defect rates and customer feedback can provide valuable insights into the product's performance.

By integrating testing and quality assurance into your PLM strategy, you can deliver high-quality products that meet market demands while minimizing risks and costs.

End-of-Life Management

End-of-life management is the final stage of the product lifecycle. It involves phasing out a product while ensuring compliance with regulations and minimizing environmental impact. Proper planning during this stage can help you reduce costs and maintain customer satisfaction.

One of the key aspects of end-of-life management is document management. Organizing compliance records and product-related documents ensures that you can address regulatory inquiries efficiently. For example, you might need to provide evidence that the product was discontinued in accordance with environmental laws. PLM tools simplify this process by centralizing all relevant information, making it easily accessible when needed.

Another critical component is adhering to safety standards and environmental regulations. PLM systems facilitate this by automating quality checks and ensuring that your product meets the necessary requirements throughout its lifecycle. This not only helps you avoid legal issues but also demonstrates your commitment to sustainability.

To implement effective end-of-life management, you should assess your organization's needs and existing processes. Establishing key performance indicators (KPIs) allows you to measure the success of your strategy and identify areas for improvement. For example, tracking the efficiency of recycling programs or the cost of product disposal can provide valuable insights.

By incorporating end-of-life management into your PLM framework, you can ensure a smooth transition for discontinued products while maintaining compliance and reducing environmental impact.

Benefits of Product Lifecycle Management

Enhancing Team Collaboration

Product lifecycle management fosters stronger collaboration among teams by centralizing product-related information. When everyone accesses the same data, communication improves, and misunderstandings decrease. You can streamline processes and ensure that all stakeholders work toward shared goals.

Reducing Time-to-Market

Reducing time-to-market is a critical advantage of product lifecycle management. PLM strategies optimize design and production processes, enabling you to launch products faster. For example, a leading consumer electronics company reduced its product development cycle by 30% using agile and digital tools. Similarly, manufacturers have reported up to a 25% decrease in development cycles by leveraging PLM systems.

With PLM, you can automate workflows, eliminate redundant tasks, and focus on innovation. Real-time data sharing ensures that teams address issues promptly, preventing delays. By accelerating your product's journey from concept to market, you gain a competitive edge and meet customer demands more effectively.

Improving Product Quality and Compliance

PLM enhances product quality and ensures compliance with regulatory standards. Establishing a centralized repository for compliance data creates a single source of truth, making it easier to track and verify adherence. Automated compliance checkers further streamline processes by identifying potential issues at each lifecycle stage.

You can also maintain detailed audit trails to document compliance efforts. These records prove invaluable during audits and help you address regulatory inquiries efficiently. Collaboration between teams allows you to leverage compliance knowledge throughout product development, ensuring that your product meets industry standards.

Integrating risk management processes into PLM minimizes compliance risks from the start. This proactive approach not only improves product quality but also builds customer trust. By adopting PLM, you deliver products that meet expectations while adhering to legal and environmental requirements.

Cost Savings Through Efficient Resource Management

Efficient resource management plays a vital role in reducing costs throughout the product lifecycle. By optimizing how you allocate resources, you can eliminate waste and improve productivity. Product lifecycle management (PLM) systems provide tools to help you achieve this goal. These systems centralize data, enabling you to track resource usage and identify areas for improvement.

PLM allows you to streamline workflows and automate repetitive tasks. For example, you can use PLM software to monitor material consumption during production. This helps you avoid overstocking or underutilizing resources. Additionally, PLM systems provide insights into historical data, allowing you to forecast demand and plan accordingly. Accurate forecasting reduces the risk of excess inventory and minimizes storage costs.

Real-World Applications of PLM with FanRuan

FanRuan demonstrates how PLM can transform businesses across industries. Its FineDataLink platform integrates seamlessly with PLM systems, enabling you to manage data effectively. This integration enhances collaboration, accelerates workflows, and improves decision-making.

FineDataLink supports real-time data synchronization, ensuring that your product-related information remains accurate and up-to-date. For example, manufacturers can use FineDataLink to monitor production schedules and adjust them based on demand. This reduces downtime and ensures efficient resource utilization.

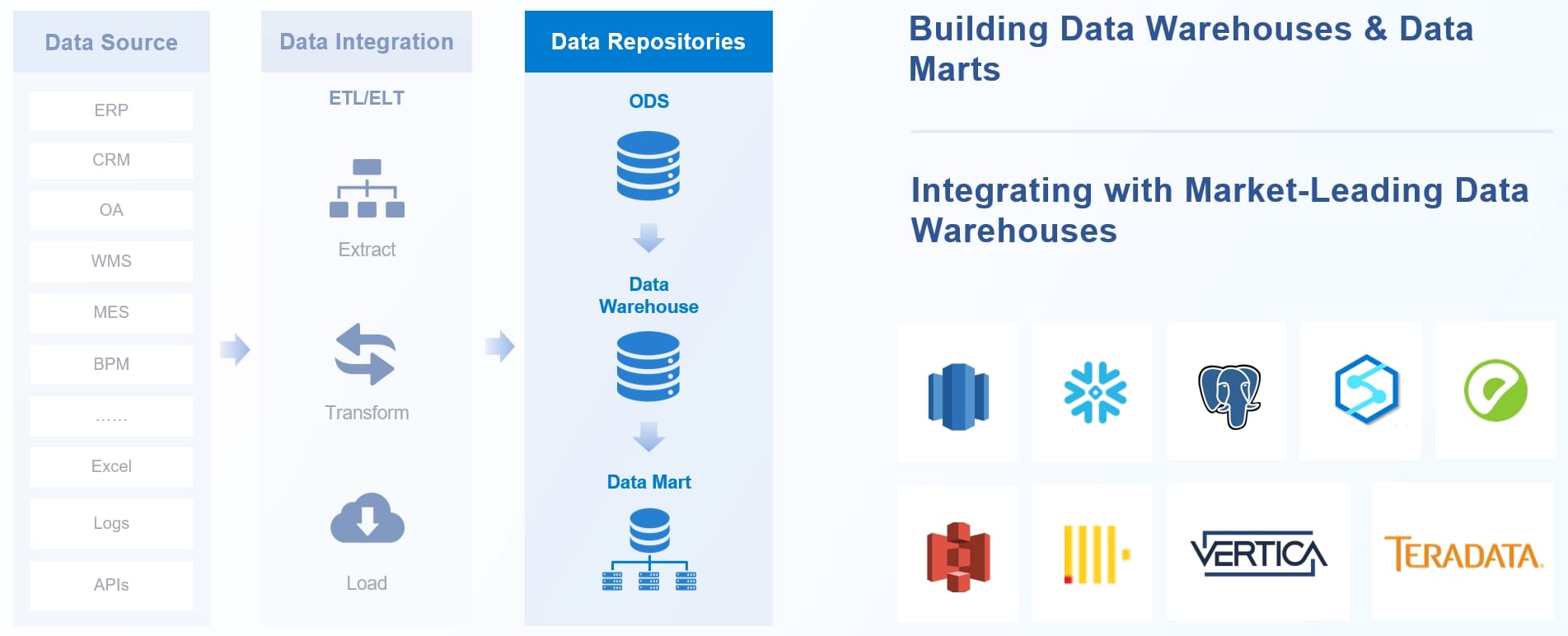

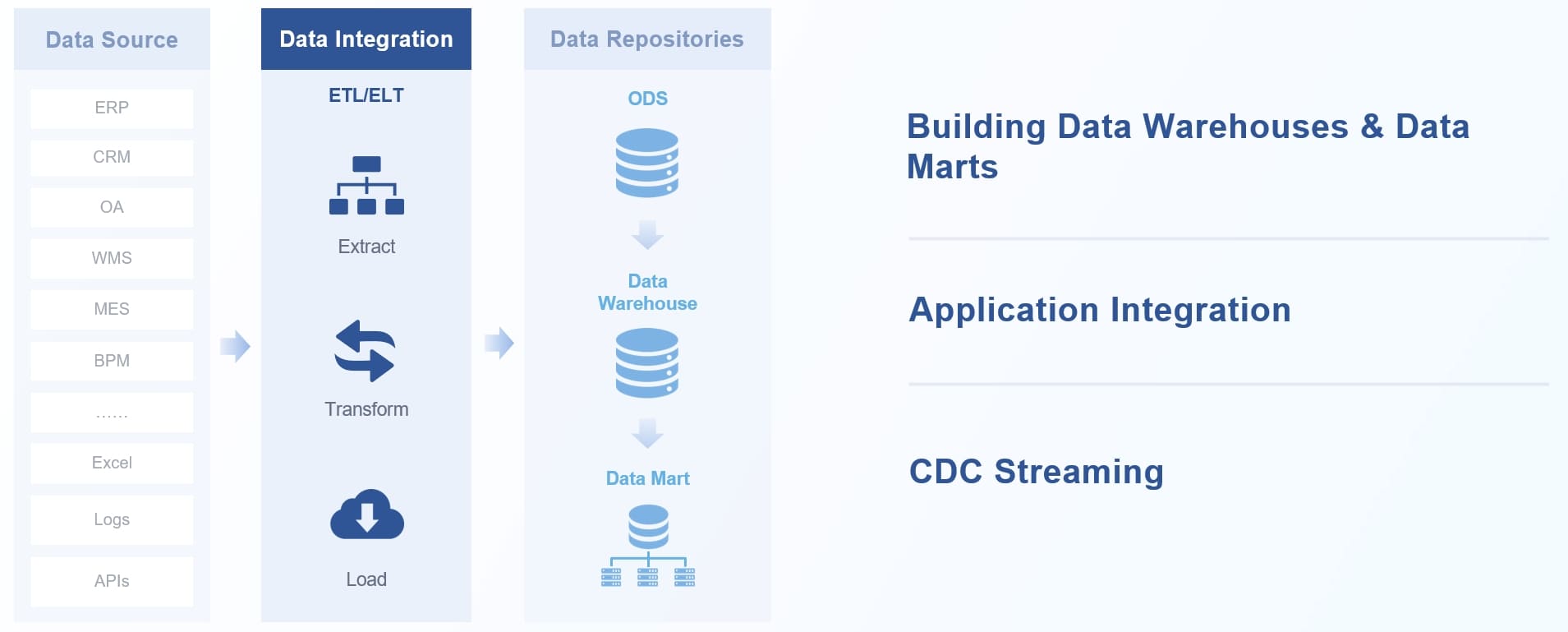

The platform's ETL/ELT capabilities simplify data preprocessing, making it easier to analyze trends and forecast market needs. By leveraging these insights, you can optimize product design and development processes. FineDataLink also offers API integration, allowing you to connect PLM systems with other tools. This creates a unified environment where data flows seamlessly between departments.

FanRuan's solutions have benefited companies like A.O. Smith and Red Bull. These organizations have used FineDataLink to enhance safety management, streamline manufacturing, and improve data governance. By adopting FanRuan's tools, you can unlock the full potential of PLM and drive business success.

FineDataLink empowers you to build a high-quality data layer for PLM. This ensures that your product lifecycle processes remain efficient, cost-effective, and aligned with market demands.

How FineDataLink Supports Product Lifecycle Management

Real-Time Data Synchronization for PLM

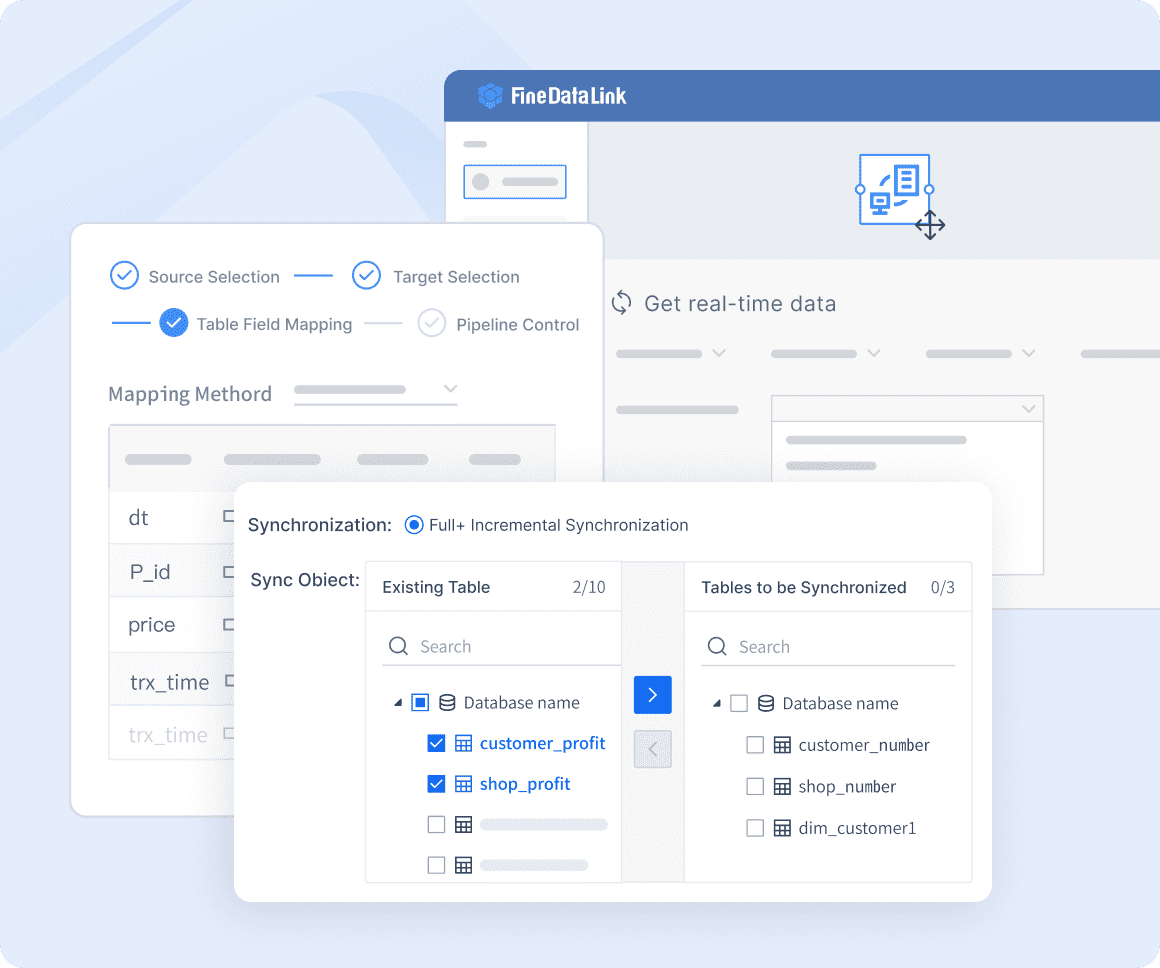

Real-time data synchronization ensures that your product-related information stays accurate and up-to-date across all systems. FineDataLink excels in this area by enabling you to synchronize data across multiple tables with minimal latency, often measured in milliseconds. This capability proves invaluable for tasks like database migration, real-time reporting, and building a live data warehouse.

For example, when managing a product's lifecycle, you can use FineDataLink to monitor production schedules and adjust them dynamically based on demand. This reduces downtime and ensures that resources are allocated efficiently. Real-time synchronization also enhances collaboration by providing all stakeholders with immediate access to the latest data. This level of connectivity helps you make faster, more informed decisions, keeping your product lifecycle on track.

Advanced ETL/ELT Capabilities in PLM Processes

FineDataLink simplifies complex data transformation tasks through its advanced ETL (Extract, Transform, Load) and ELT (Extract, Load, Transform) capabilities. These features allow you to preprocess data efficiently, ensuring that it is ready for analysis and decision-making.

For instance, you can use FineDataLink to clean and structure raw data from various sources, making it easier to identify trends and forecast market needs. This is particularly useful during the design and development phases of the product lifecycle, where accurate data plays a critical role in shaping strategies. By automating these processes, FineDataLink reduces manual effort and minimizes errors, allowing you to focus on innovation and quality improvement.

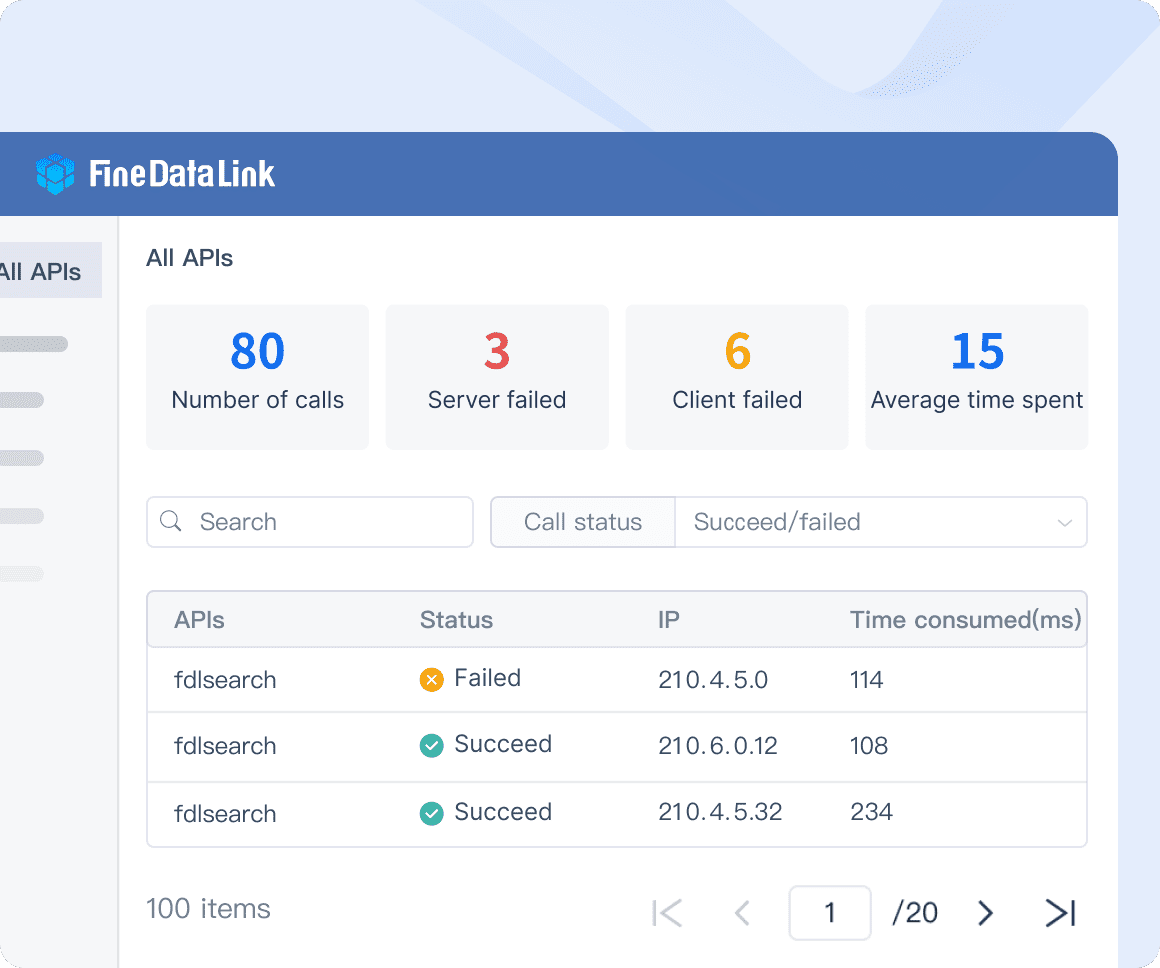

API Integration for Seamless Data Flow in PLM

API integration is essential for creating a unified environment where data flows seamlessly between systems. FineDataLink offers a low-code platform that allows you to develop and launch APIs in just five minutes. This feature enables you to connect PLM systems with other tools, such as ERP or CRM platforms, without extensive coding.

Several real-world examples highlight the effectiveness of API integration. The Icertis platform, for instance, uses over 200 APIs to facilitate data flow between contract management and other systems. Daimler successfully integrated Icertis' software with SAP and Microsoft technologies, achieving seamless data flow and operational efficiency. Gartner also recognized Icertis' API-first approach as a key differentiator in complex projects.

With FineDataLink, you can achieve similar results by streamlining communication between your PLM system and other enterprise applications. This integration enhances visibility, reduces miscommunication, and ensures that all teams work with consistent, up-to-date information.

Building a High-Quality Data Layer for PLM with FineDataLink

A high-quality data layer forms the foundation of effective Product Lifecycle Management (PLM). It ensures that your product-related data remains accurate, accessible, and actionable throughout the lifecycle. FineDataLink empowers you to build this essential layer with its advanced data integration capabilities.

FineDataLink centralizes data from multiple sources, creating a unified repository. This eliminates data silos and ensures that all teams work with consistent information. For example, you can integrate data from design, manufacturing, and supply chain systems into a single platform. This approach improves collaboration and decision-making across departments.

Tip: A centralized data layer reduces errors caused by outdated or inconsistent information, saving you time and resources.

Real-time data synchronization is another key feature of FineDataLink. It allows you to update and share data instantly across systems. For instance, if a design change occurs, the updated information becomes immediately available to manufacturing teams. This minimizes delays and ensures that your product development stays on track.

FineDataLink also simplifies data transformation with its ETL/ELT capabilities. You can preprocess raw data, making it ready for analysis and reporting. This helps you identify trends, forecast market needs, and optimize your product strategies. Additionally, the platform’s low-code API integration enables seamless communication between PLM and other enterprise systems.

By leveraging FineDataLink, you can create a robust data layer that supports every stage of the product lifecycle. This ensures that your PLM processes remain efficient, accurate, and aligned with your business goals.

Building a high-quality data layer with FineDataLink not only enhances operational efficiency but also gives you a competitive edge in today’s fast-paced market.

Product lifecycle management helps you oversee every stage of a product's journey, from concept to retirement. It ensures efficiency, quality, and collaboration across teams. The core components, such as product data management and supply chain collaboration, streamline processes and improve decision-making. Tools like FineDataLink enhance these processes by centralizing data, enabling real-time synchronization, and simplifying integration. By adopting PLM and leveraging FineDataLink, you can optimize workflows, reduce costs, and deliver high-quality products that meet market demands.

FAQ

PLM helps you manage a product's journey from concept to retirement. It ensures efficiency, improves collaboration, and enhances product quality. By centralizing data and streamlining processes, PLM enables you to make informed decisions and adapt to market demands effectively.

PLM centralizes product-related data, ensuring everyone accesses the same information. This reduces miscommunication and enhances teamwork. You can align efforts across departments, streamline workflows, and achieve shared goals more efficiently.

Yes, PLM optimizes resource allocation and eliminates redundant tasks. By automating workflows and improving data accuracy, you can minimize waste and avoid costly errors. Historical data within PLM also helps you forecast demand and plan resources effectively.

Real-time data synchronization ensures that all stakeholders work with the latest information. It reduces delays, enhances decision-making, and improves responsiveness to market changes. Tools like FineDataLink enable you to synchronize data instantly, keeping your processes efficient and accurate.

FineDataLink enhances PLM by centralizing data, enabling real-time synchronization, and simplifying integration with other systems. Its ETL/ELT capabilities streamline data preprocessing, while its low-code API integration ensures seamless communication between tools. These features improve efficiency and decision-making throughout the product lifecycle.