If you want to stay competitive in manufacturing, you need the best manufacturing management software. Leading solutions like FanRuan’s FineReport, NetSuite, SAP S/4HANA, and Epicor Kinetic stand out in 2025. You see these solutions driving efficiency, real-time data access, and seamless integration.

- By 2025, 76% of manufacturers have started smart manufacturing initiatives.

- 98% of global manufacturers now begin their digital transformation journey.

These manufacturing management software solutions help you optimize workflows, automate processes, and improve decision-making. Choosing the right management platform ensures your operations align with digital transformation and future trends.

Top Solutions

Manufacturing Management Software

You have many choices when it comes to manufacturing management software in 2025. Leading companies like FanRuan, Siemens, ABB, SAP, NetSuite, Epicor Kinetic, and Dassault Systems continue to shape the market. These solutions help you manage complex manufacturing operations, streamline production, and improve decision-making.

Industry analysts project that Siemens and ABB will maintain strong positions with their manufacturing operations management software, especially in the automotive segment. North America leads in technology adoption, while Asia-Pacific shows the fastest growth.

Here is a quick comparison of top players:

| Company | Strengths & Focus Areas | Regional Insights |

|---|---|---|

| FanRuan (FineReport) | Advanced analytics, smart factory dashboards, mobile BI, easy integration | Strong in Asia-Pacific, expanding globally |

| Siemens | MES, MOM, cloud-based solutions, industry-specific expertise | US leads, Asia-Pacific growing |

| ABB | MOM, cloud, strong in North America and Europe | Growth in Asia-Pacific |

| SAP S/4HANA | ERP, MOM, strategic partnerships, technology integration | Global presence |

| NetSuite | Cloud ERP, scalable for small and medium manufacturers | Global reach |

| Epicor Kinetic | Cloud ERP, manufacturing analytics, flexible deployment | Strong in US and Europe |

| Dassault Systems | MOM, industry-specific solutions | Active globally |

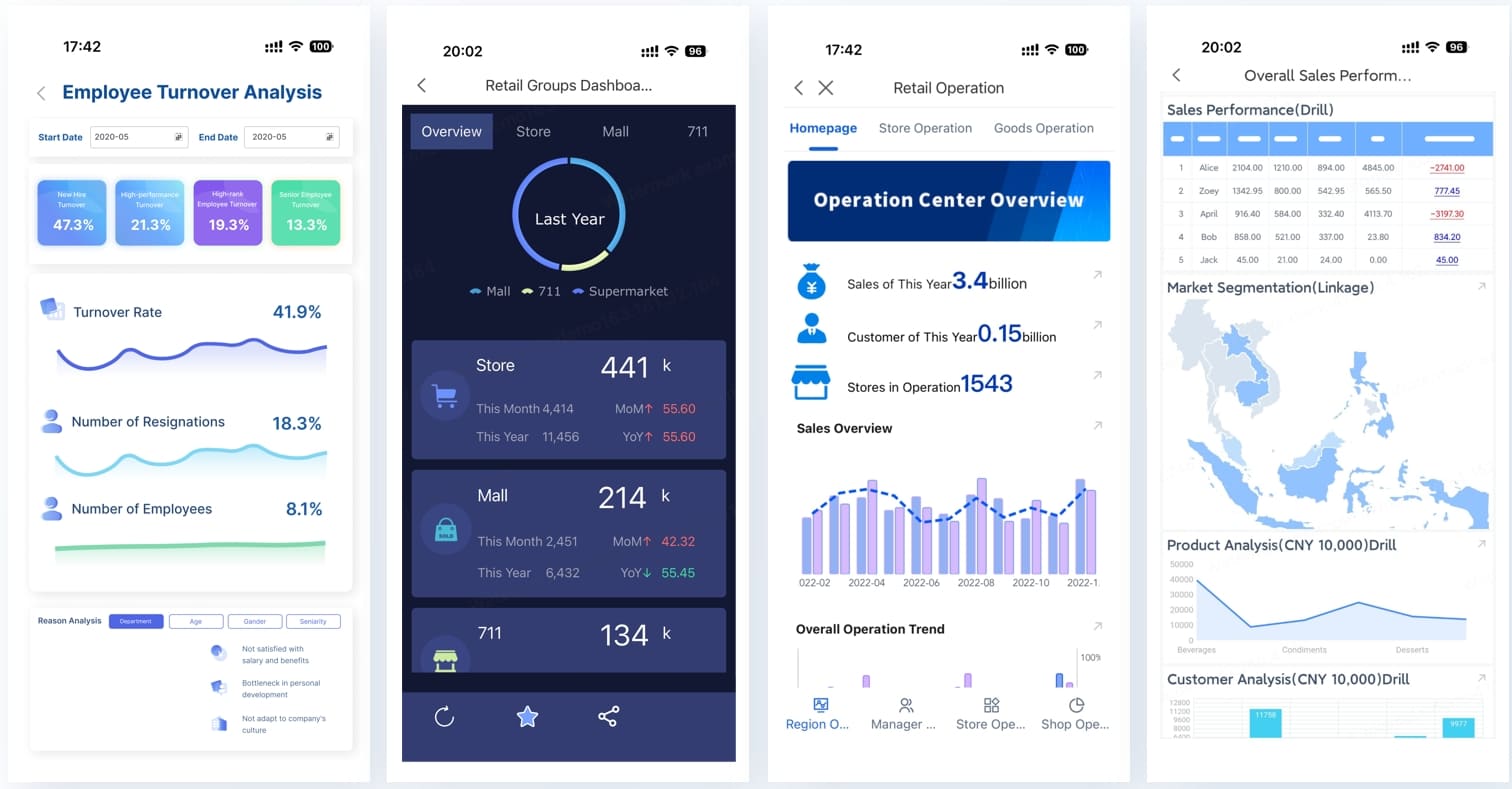

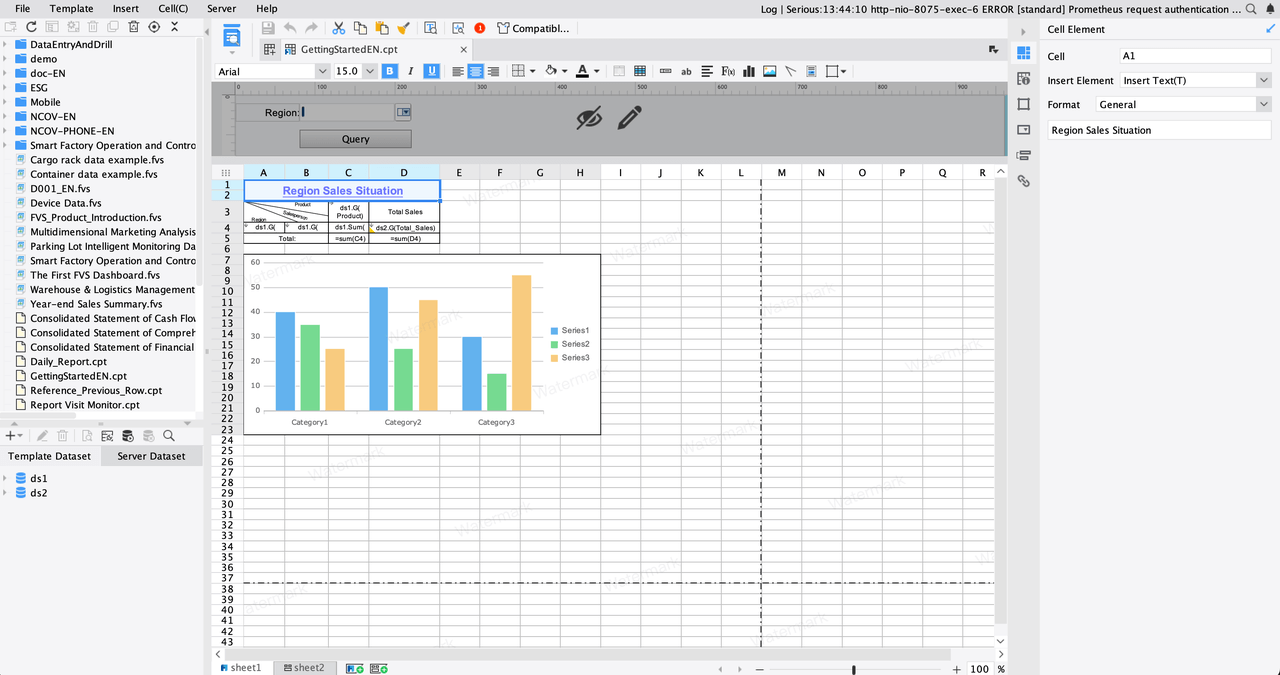

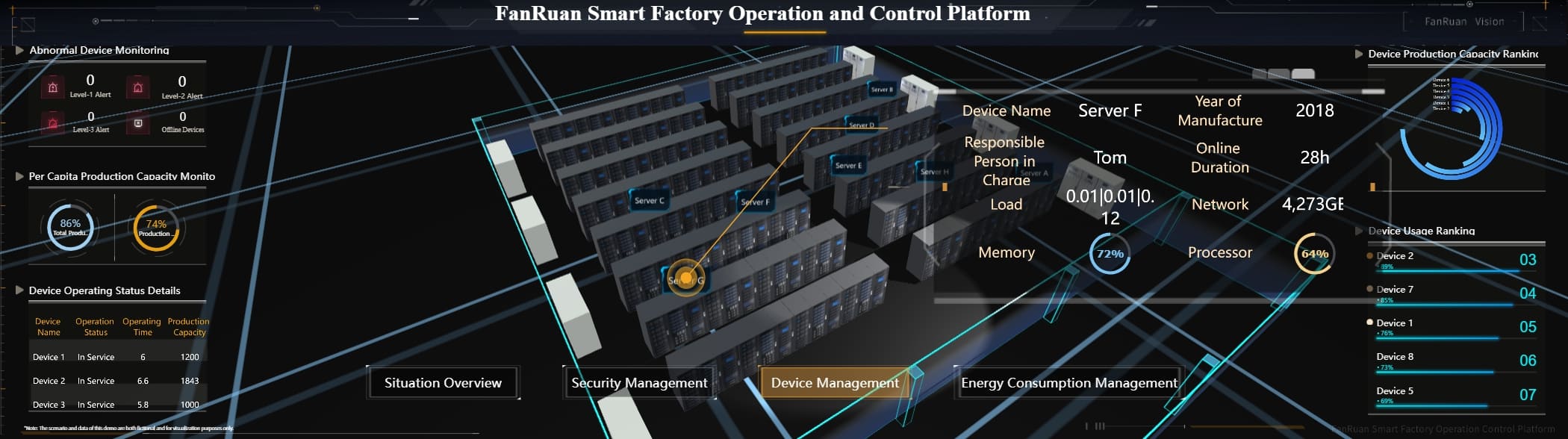

FanRuan’s FineReport stands out for its user-friendly drag-and-drop report design, strong BI reporting, and mobile dashboards. You can quickly build custom dashboards to monitor key performance indicators across your production lines. FineReport specializes in funnel analysis, competitive intelligence, and communication management, making it ideal for manufacturers who need deep analytic insights and streamlined communication.

You will find that these solutions address common challenges in manufacturing. They integrate with ERP and MES systems to avoid data silos. Automated inventory tracking and built-in quality control workflows help you reduce manual work and errors. Visual production floor planning and digital twins give you a real-time view of your operations. AI-driven scheduling predicts delays and automatically adjusts production schedules, helping you minimize downtime and keep production on track.

Manufacturing ERP Software

Manufacturing ERP software forms the backbone of modern production management. You can use ERP to centralize data from all departments, including supply chain, inventory, production, and finance. Top ERP solutions like SAP S/4HANA, NetSuite, Epicor Kinetic, and Microsoft Dynamics 365 offer cloud-based ERP options that support real-time data access and analytics.

ERP systems help you improve operational efficiency and resource utilization. You can enhance production planning, supply chain management, and decision-making with real-time data. ERP reduces inventory and labor costs, giving you better control over resources. You also gain improved demand planning and customer service.

ERP software integrates data from all company functions, providing a comprehensive view of your organization. You can track supply, scheduling, inventory, and other critical information, harmonizing operations and procedures. This integration supports better production planning and resource management, especially for small and medium-sized manufacturers.

Cloud-based ERP platforms offer scalability and flexibility. You can adapt to growing data volumes and evolving business needs. Automation features in ERP reduce manual tasks and improve decision-making. For example, ERP integration can automate field data entry, reducing invoicing time from weeks to hours. ERP-CRM integration automates sales quoting, eliminating manual re-entry and errors.

You benefit from unified analytics and real-time visibility. Integration with IoT and AI supports predictive maintenance and smart manufacturing. ERP helps you optimize production, reduce waste, and improve productivity.

CMMS Overview

A CMMS, or computerized maintenance management system, is essential for keeping your equipment running smoothly. You use CMMS to schedule preventive maintenance, track repairs, and manage spare parts inventory. Leading CMMS solutions include IBM Maximo, Fiix, UpKeep, and eMaint. Many ERP vendors, such as SAP and Oracle, also offer integrated CMMS modules.

You can connect your CMMS with ERP and MES systems to create a unified view of your manufacturing operations. This integration helps you avoid data silos and ensures that maintenance activities align with production schedules. Automated workflows in CMMS reduce manual data entry and errors. You can digitize repetitive tasks and embed AI, machine learning, and IoT to optimize production and improve decision-making.

CMMS solutions help you minimize downtime by enabling preventive maintenance and predictive maintenance. You can track equipment performance in real time, identify issues before they cause failures, and schedule repairs efficiently. This approach reduces unplanned downtime and extends equipment life.

You also benefit from collaboration tools in CMMS that enable real-time updates and communication across teams. Security and compliance features protect sensitive data through encryption, access controls, and audits.

With a modern CMMS, you can achieve faster time to market, optimized inventory management, enhanced compliance, and reduced operational costs. You keep your production lines running efficiently and support continuous improvement in your manufacturing environment.

Features of Manufacturing Management Software

Integration

You need seamless integration to maximize the value of your manufacturing management software. Integration with ERP, CMMS, and cloud platforms connects your manufacturing operations, production data, and business processes. You can link eCommerce channels and POS systems for real-time stock updates, which prevents overselling and improves customer satisfaction. Connecting with accounting software like QuickBooks, Sage 50, Xero, and Shopify supports financial management alongside manufacturing. Warehouse management systems and manufacturing execution systems facilitate automated purchase order management and real-time inventory tracking across multiple locations. Batch and lot tracking enhance traceability and accuracy in inventory management.

- Integration reduces manual errors and optimizes supply chain and production planning.

- You benefit from data-driven decision-making and flexible deployment.

- Advanced integration models show that transferring labor and increasing technological inputs lead to higher industrial chain output growth rates.

FanRuan’s FineReport offers open APIs and supports integration with ERP, MES, and CMMS, making it easy to connect your systems and scale as your manufacturing needs grow.

Real-Time Data

Real-time data is essential for modern manufacturing. You gain real-time visibility into production activities, equipment status, and operational KPIs. This immediate access helps you detect issues early, coordinate teams, and make confident decisions quickly. Manufacturers using real-time monitoring report up to a 20% increase in production efficiency and significant reductions in downtime.

- Real-time data provides a transparent view of operations, helping you identify bottlenecks and predict preventive maintenance needs.

- You can respond dynamically to production challenges and optimize resource use.

- Mobile dashboards in FineReport deliver real-time insights into production status, performance metrics, and operational data from operators, machines, and devices.

- You track work orders, batches, and units, monitor cycle times, output, first pass yield, uptime, and quality indicators.

- Mobile accessibility allows you to input data, upload photos, and monitor operations anywhere on the factory floor.

- Dashboards aggregate data into customizable views, helping you prioritize improvement projects and streamline communication.

Automation

Automation transforms your manufacturing operations. You automate repetitive tasks, reduce manual data entry, and improve production efficiency. ERP and CMMS systems support automated workflows for preventive maintenance, inventory management, and production scheduling.

- Automation enables predictive maintenance, reducing downtime and extending equipment life.

- You benefit from streamlined communication and faster response to issues.

- Cloud-based ERP and CMMS platforms offer scalable automation, adapting to your evolving manufacturing needs.

- Automated alerts and AI-powered analyses in dashboards help you address problems before they impact production.

- Automation supports continuous improvement and helps you maintain competitiveness in the manufacturing industry.

Tip: When you choose manufacturing management software with strong integration, real-time visibility, and automation, you unlock the full benefits of digital transformation. You optimize production, reduce downtime, and improve decision-making across your manufacturing operations.

Comparison

Strengths

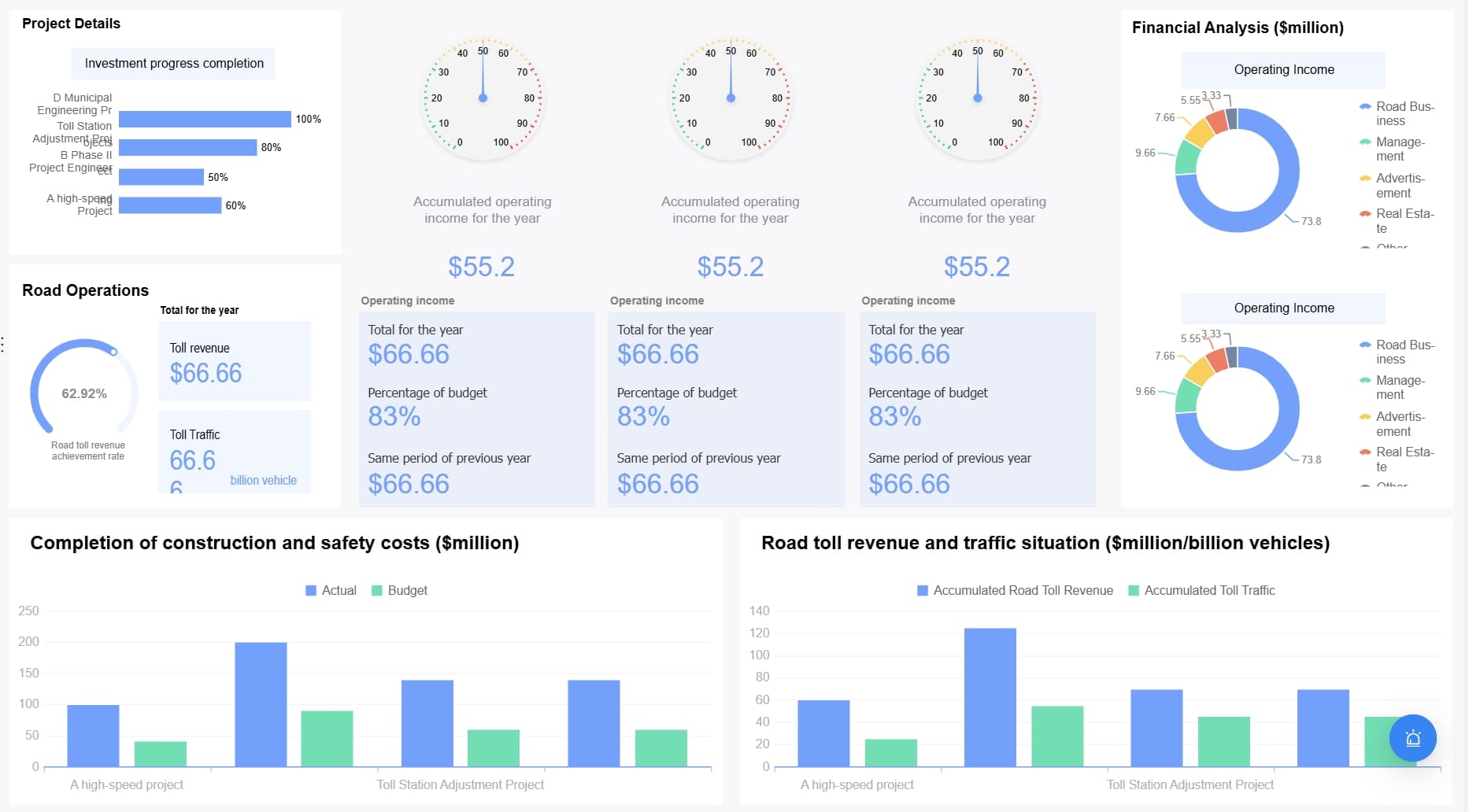

You want to choose solutions that deliver the strongest results for your manufacturing operations. FineReport gives you advanced analytics, smart factory dashboards, and seamless integration with ERP and CMMS platforms. NetSuite offers cloud-based ERP with unified business insights, strong financial management, and real-time analytics. SAP S/4HANA stands out for integrating AI, machine learning, and predictive analytics, supporting process automation and compliance. Epicor Kinetic excels in real-time monitoring, quality management, and global financial integration, making it ideal for discrete manufacturers.

You can reduce equipment downtime and improve preventive maintenance by using CMMS features in these solutions. Real-time data and automation help you minimize downtime and keep your production lines running efficiently.

Target Users

You need to match solutions to your manufacturing environment. FineReport works well for manufacturers seeking flexible analytics, equipment management, and smart factory solutions. NetSuite fits large manufacturers with multiple facilities that require scalable ERP and complex management. SAP S/4HANA supports global enterprises needing advanced ERP, compliance, and predictive analytics. Epicor Kinetic serves mid-market discrete manufacturers who want robust ERP, CMMS, and real-time monitoring.

| Solution | Best Suited Manufacturer Type | Key Features / Notes |

|---|---|---|

| FineReport | Manufacturers needing analytics and dashboards | Smart factory dashboards, equipment management, CMMS integration |

| NetSuite | Large manufacturers with multiple facilities | Cloud ERP, financial management, real-time analytics |

| SAP S/4HANA | Global enterprises | AI, machine learning, predictive analytics, compliance |

| Epicor Kinetic | Mid-market discrete manufacturers | Real-time monitoring, quality management, global ERP |

Unique Capabilities

You gain unique capabilities from each solution. FineReport lets you create custom dashboards for manufacturing analytics, monitor equipment downtime, and integrate CMMS for preventive maintenance. NetSuite provides mobile ERP and unified business insights for complex management needs. SAP S/4HANA delivers real-time insights with AI and predictive analytics, supporting compliance and automation. Epicor Kinetic offers user-friendly design, global support, and strong CMMS features for equipment management.

- You can use CMMS modules to track equipment downtime, schedule preventive maintenance, and optimize asset management.

- ERP integration across these solutions ensures you manage production, inventory, and supply chain efficiently.

- FineReport stands out for its ability to visualize manufacturing data, automate reporting, and support agile decision-making.

| ERP System | Strengths in Manufacturing Analytics |

|---|---|

| FineReport | Advanced analytics, smart factory dashboards, CMMS integration, equipment management |

| NetSuite ERP | Cloud-based, strong financial management, inventory, supply chain, real-time analytics, mobile ERP capabilities |

| SAP S/4HANA | AI, machine learning, predictive analytics, real-time insights, process automation, compliance, scalable ERP |

| Epicor Kinetic | Real-time monitoring, quality management, global financial integration, user-friendly, robust CMMS for equipment |

You can select the right solution by considering your manufacturing size, management needs, and the importance of ERP and CMMS integration.

Selection Guide of Manufacturing Management Software

Business Needs

When you select manufacturing management software, start by identifying your business needs. Your company size and growth plans shape your requirements.

- Small manufacturers often need MRP systems that focus on production and inventory control.

- Medium and large manufacturers benefit from erp solutions with broader features for finance, HR, and customer management.

- If you plan to scale, choose cloud solutions that offer flexibility and customization.

- Real-time data tracking across production and supply chain improves efficiency and traceability.

- Consider total cost of ownership, including implementation, support, and training.

FanRuan’s FineReport gives you a flexible platform that adapts to your business, supporting both small teams and large enterprises. You gain benefits like improved efficiency, better production planning, and strong analytics.

Workflows

Your workflows determine which solutions fit best.

- If you need quality control, inventory management, and collaboration, look for erp or MES software that supports these tasks.

- For production planning, choose software that automates scheduling and tracks real-time production metrics.

- Warehouse management systems help with inventory and order fulfillment.

- Automation software reduces manual work and boosts efficiency.

- Traceability tools ensure compliance and supply chain visibility.

- Integrated platforms like FineReport support agile production planning, analytics, and workflow automation.

You improve efficiency and reduce delays by matching software features to your production needs.

Integration

Integration is a key factor in successful software adoption. You want your new system to work with existing erp, MES, and production tools.

| Integration Challenge | Description | Best Practice |

|---|---|---|

| Data Migration | Moving data from old to new systems can cause errors | Use standardized data and mapping tools |

| System Compatibility | Different platforms may not connect easily | Choose open standards and upgrade infrastructure |

| Customization | Tailoring software can lead to misconfiguration | Define clear requirements and test incrementally |

| Integration Complexity | Overlapping processes can slow down production | Integrate critical systems first |

| Ongoing Support | Updates may disrupt workflows | Schedule maintenance and provide user training |

You avoid data silos and maintain operational continuity by selecting solutions with open APIs and strong support. FineReport excels in integration, making it easy to connect with erp, cloud, and production systems. This ensures you maximize the benefits of digital transformation and maintain high efficiency.

Trends

AI and Automation

You see AI and automation transforming manufacturing management software in 2025. Intelligent robotics now adapt to dynamic environments and work safely with people on the factory floor. AI-powered robotics and vision systems improve workflow efficiency and reduce human error. Predictive maintenance and inventory optimization help you schedule just-in-time repairs and avoid excess inventory. You benefit from AI-driven quality control, which uses vision inspection to catch defects faster and more accurately than humans.

- Collaborative robots, or cobots, address labor shortages and boost flexibility.

- Edge computing and digital twins enable real-time decision-making and operational resilience.

- Hyperautomation combines AI, machine learning, and robotic process automation to streamline your operations.

- Industrial cybersecurity powered by AI protects your systems from threats.

- You also see AI supporting sustainability by optimizing energy use and reducing waste.

FanRuan demonstrates a strong commitment to innovation by offering real-time data statistics, clear process flows, and rapid adaptation to changing business needs.

Cloud Solutions

Cloud-based solutions now lead the way in manufacturing management. You gain faster deployment, lower costs, and easier upgrades with cloud-based ERP and MES platforms.

- Cloud ERP systems update automatically, so you always have the latest features without downtime.

- Security shifts to vendors, who invest in advanced protection, reducing your risk.

- Cloud ERP improves efficiency by automating processes and streamlining operations.

- Real-time analytics and integration help you plan production and make better decisions.

- Cloud-based solutions support digital transformation by unifying business data and enabling cross-team collaboration.

Cloud MES reduces total cost of ownership by about 30% compared to on-premises systems. You can scale quickly, add users on demand, and break down data silos for more actionable insights. Cloud-based solutions also support agility, letting you pivot to meet changing demands.

Sustainability

Sustainability shapes the future of manufacturing management software. You now track energy, water, and material usage in real time to reduce waste and improve resource efficiency. Automated workflows simplify compliance reporting and audits.

- Centralized environmental data management helps you meet regulatory standards.

- You monitor carbon emissions, water use, and waste, aligning compliance with broader sustainability goals.

- Real-time data supports corrective action plans and continuous improvement.

- You can reduce reporting time and audit preparation from days to minutes.

Manufacturers using these solutions have cut compliance violations and met sustainability targets ahead of schedule. FanRuan’s solutions help you collect and analyze environmental data, supporting your sustainability initiatives and building stakeholder trust.

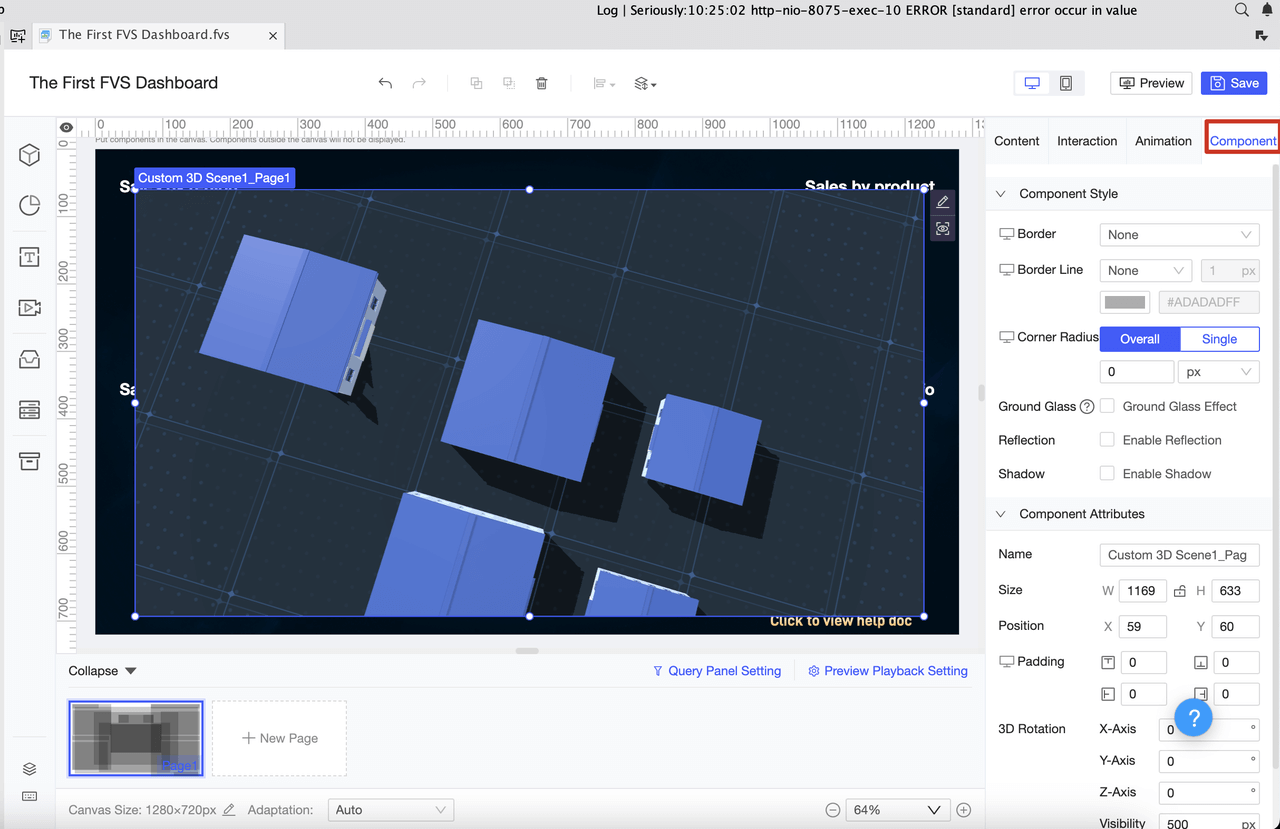

Core Application Scenarios of Manufacturing Management Software FineReport

Monitoring and Alert: Real-Time Data Application

You need real-time visibility to keep your manufacturing operations safe and efficient. FineReport’s Data Alert plugin lets you set up dynamic alerts for dashboard reports. You can filter data by time, such as today or last week, and trigger notifications when abnormal conditions appear. Assign alerts to specific users or departments, so the right people respond quickly. WebSocket support enables high-frequency data refresh, giving you instant updates and improving your response time.

- You track equipment downtime and receive alerts with assignee and resolution time settings, ensuring issues get resolved fast.

- Mobile adaptation allows you to monitor data changes anywhere, increasing your responsiveness on the shop floor.

- Video monitoring components let you access real-time video streams, adding another layer of safety.

These features help you detect problems early, reduce equipment downtime, and maintain high production standards.

Paperless Operations

You can transform your manufacturing workflows by going paperless. Digital platforms eliminate paper-related costs and speed up production processes.

| Benefit | Explanation |

|---|---|

| Cost Savings | You save money by removing paper production, storage, and disposal expenses. |

| Increased Efficiency & Productivity | Digitized work instructions and reporting reduce errors and delays. |

| Improved Quality Control | Digital records ensure data accuracy and consistency. |

| Enhanced Traceability | Real-time visibility of product lifecycle data supports compliance. |

| Better Collaboration | Teams share data easily through digital platforms. |

| Environmental Impact Reduction | Less paper means less waste and lower carbon emissions. |

| Seamless ERP and MES Integration | Real-time data sharing optimizes scheduling and planning. |

| Optimized Production Scheduling | Flexible scheduling adapts to real-time visibility. |

| Shorter Lead Times | Faster delivery through real-time order tracking. |

| Increased Security | Encryption and access controls protect your data. |

Recent case studies show that paperless manufacturing can boost performance by 20%. You gain instant access to information, reduce labor costs, and support sustainable growth.

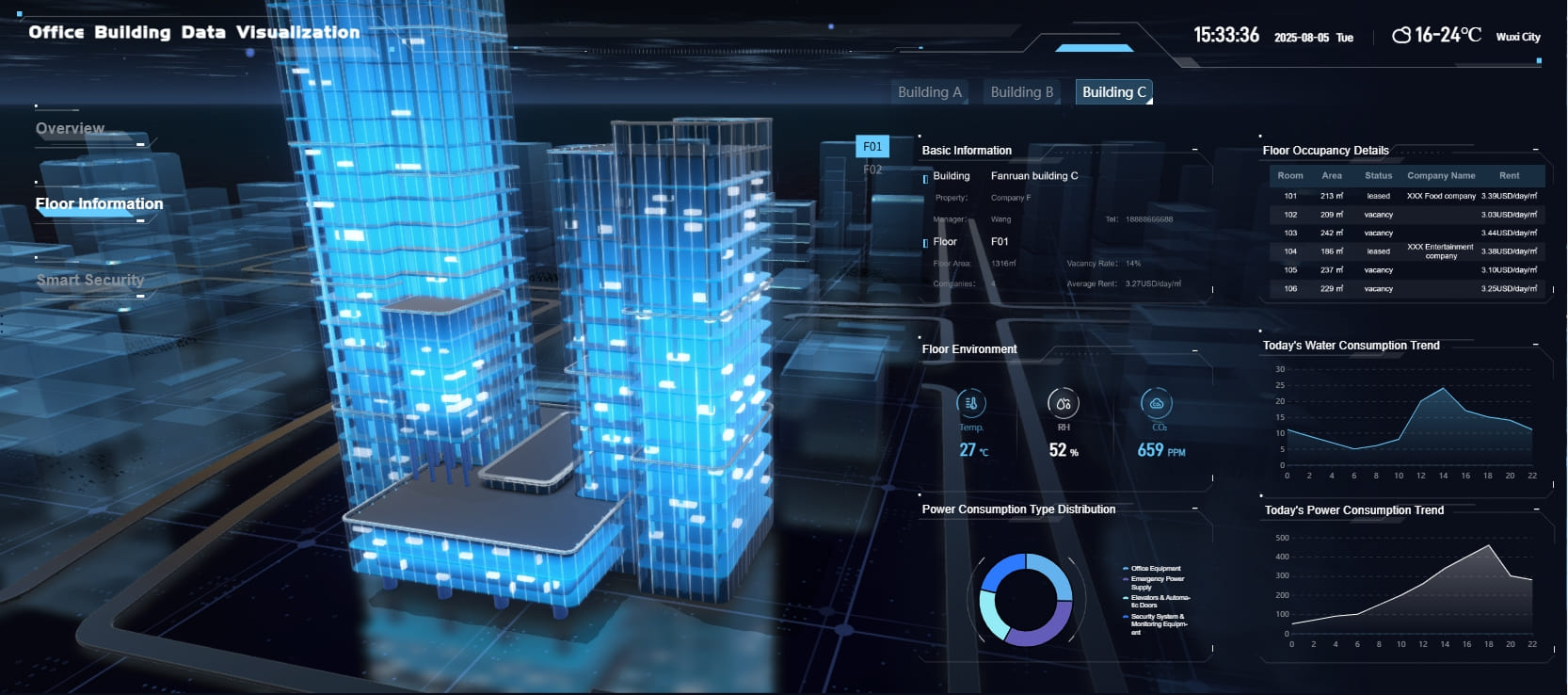

Diverse Data Visualization Formats

FineReport gives you powerful visualization tools to improve decision-making and operational visibility.

3D Dashboard

You use 3D dashboards to display spatial and temporal data.

- 3D Earth visualizes geographic information, helping you manage resources across regions.

- 3D panoramic maps show dynamic asset and personnel movements, supporting real-time monitoring.

- Track maps animate logistics fleets, letting you track millions of routes and reduce equipment downtime.

- Bullet maps and dynamic water balloons present performance metrics and progress in a clear, animated format.

General Dashboard

General dashboards offer flexible layouts and interactive charts.

| Visualization Format | Function & Features | Application & Decision-Making Support |

|---|---|---|

| Flowchart | Visualizes business processes for easy optimization. | You clarify workflows and reduce communication costs. |

| Mini Figure | Embeds trend charts in reports. | You assess business trends quickly. |

| Combination Chart | Integrates bar and pie charts with animation. | You understand complex data relationships. |

| Sankey Diagram | Shows flows and compositions. | You analyze resource or financial flows for strategic planning. |

| Pictogram | Uses graphical figures for data values. | You interpret data easily in reports. |

These visualization formats give you real-time visibility into your manufacturing data, helping you make faster, smarter decisions.

You gain the most value when you align your software choice with your business goals and future trends.

Review the comparison table below to see how leading ERP platforms fit different business sizes and needs:

| ERP Platform | Target Business Size | Cloud Deployment | Mobile Access | Key Manufacturing Features |

|---|---|---|---|---|

| Oracle Cloud ERP | Enterprise | Yes | Yes | AI-driven analytics, advanced planning, supply chain management |

| SAP S/4HANA | All | Yes | Yes | Real-time analytics, comprehensive manufacturing suite |

| Microsoft Dynamics 365 | Mid-market to Enterprise | Yes | Yes | Mixed-mode manufacturing, IoT integration, CRM |

To stay ahead, follow these steps:

- Assess your business requirements and current processes.

- Request demos from leading providers like FanRuan.

- Involve key stakeholders and use structured evaluation frameworks.

- Invest in ongoing research, skill development, and change management.

Click the banner below to try FineReport for free and empower your enterprise to transform data into productivity!

Continue Reading About Manufacturing Operations Software

How to Create a Manufacturing Dashboard (Step-by-Step Guide)

Mastering Data Management: A Complete Guide

FAQ

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

9 Best Supply Chain Tools for Smarter Management in 2026

Find the best supply chain tools for 2025 to boost efficiency, gain real-time insights, and achieve smarter management for your business.

Lewis

Dec 18, 2025

Top 10 Supply Chain Tracking Software for 2026

Compare the top supply chain tracking software for 2026 to boost visibility, automate workflows, and leverage AI analytics for smarter decisions.

Lewis

Dec 18, 2025

Top 10 Supply Chain Management Software for Small Businesses

See the top 10 supply chain management software comparison for small businesses in 2026. Compare features, pricing, and scalability to find your best fit.

Lewis

Dec 18, 2025