Stock management means tracking and controlling your company’s goods, materials, and products. When you use effective stock management, you boost profitability and keep customers happy. Studies show that efficient inventory management can raise profitability by over 70% in manufacturing companies. You also improve operational efficiency, making your business in Malaysia run smoother. Better stock management shortens order fulfillment times and leads to higher customer satisfaction. Data shows that smart inventory practices can predict up to 71% of customer satisfaction changes. With the right approach, you set your business up in Malaysia for steady growth and reliable service.

You need to understand that stock management is more than just counting products on shelves. Stock management means ordering, storing, tracking, and controlling every item your business in Malaysia uses. This includes raw materials, work-in-progress items, and finished goods. Many experts also call this process stock control or inventory management.

Recent industry studies show that inventory management is a strategic process. You track, control, and optimize inventory to meet your business needs efficiently in Malaysia. You balance supply and demand, which helps your company in Malaysia run smoothly. Stock management covers all inventory, from the smallest part to the final product. When you use good inventory management, you avoid shortages and reduce waste. You also make sure you always have the right products available for your customers.

Tip: Stock management is sometimes called stock control or inventory management. All three terms mean keeping your inventory organized and efficient.

You need to focus on several key elements to make your stock management effective. These elements help you answer important questions, such as whether you have the right items in stock or if you are overstocking. Good stock control gives you visibility over stock levels, ordering, storage, and tracking.

Here are the main elements of inventory management:

You can use different techniques to improve your inventory management. The table below shows some popular methods and their benefits:

| Technique | Description | Benefits |

|---|---|---|

| Economic Order Quantity | Calculates the best order size to minimize costs | Reduces storage costs and avoids stockouts |

| Just in Time (JIT) | Keeps only what you need, when you need it | Increases efficiency and reduces waste |

| Vendor Managed Inventory | Lets suppliers manage stock based on shared data | Improves responsiveness and reduces stockouts |

| ABC Analysis | Groups inventory by value and usage | Focuses on high-value items for better control |

| Lean Theory | Removes extra stock and waste from production | Boosts productivity and lowers inventory costs |

When you use these elements and techniques, you improve cash flow, reduce costs, and support business growth in Malaysia. Stock control also helps you manage new product lines and scale your operations. Effective inventory management leads to better customer service and higher profits.

Inventory management covers several types of inventory that you must track and control to keep your business in Malaysia running smoothly. Each type plays a unique role in your operations. Understanding these categories helps you apply the right inventory management strategies and improve efficiency.

Raw materials are the basic items you use to create your products. You need to manage these materials carefully to avoid production delays. Good inventory management ensures you always have enough raw materials on hand. You can track usage rates and set reorder points to prevent shortages. When you manage raw materials well, you reduce waste and keep production costs low. This step forms the foundation of effective inventory management.

Work-in-progress (WIP) includes items that are in the middle of production. Managing WIP inventory helps you spot bottlenecks and improve workflow. You can use several efficiency metrics to monitor WIP:

When you focus on these metrics, you speed up production cycles and lower costs. Real-time tracking systems and digital dashboards help you monitor WIP and make quick adjustments. Strong inventory management in this area leads to faster delivery and better quality control.

Finished goods are products ready for sale. You must align your finished goods inventory with customer demand. Effective inventory management here boosts your order fulfillment rates. Research shows that keeping the right level of finished goods supports high service levels and increases demand. If you hold too much inventory, you face higher costs. If you hold too little, you risk missing sales. The best approach balances inventory costs with the benefits of meeting customer needs.

Tip: Use demand forecasting and sales data to set optimal finished goods levels. This practice helps you respond quickly to market changes.

MRO (Maintenance, Repair, and Operations) supplies include spare parts, tools, and materials needed for equipment upkeep. Managing MRO inventory is vital for reducing operational downtime. You can track key metrics to improve efficiency:

| Metric | Description | Impact on Downtime |

|---|---|---|

| Inventory Turnover Rate | How often you use and replace inventory | Ensures parts are available, reduces downtime |

| Stockout Rate | How often items are unavailable when needed | Fewer stockouts mean less downtime |

| Lead Time | Time suppliers take to deliver after ordering | Shorter lead times reduce downtime risk |

| Fill Rate | Percentage of orders filled completely | High fill rates keep operations running |

When you manage MRO supplies well, you keep equipment running and avoid costly delays. Inventory management in this area also helps you control maintenance costs and improve reliability.

You need to manage inventory carefully to keep your business in Malaysia healthy. Inventory management directly affects your cash flow. When you buy more stock than you need, you tie up cash that could be used elsewhere. If you keep too little, you risk missing sales and disappointing customers. The cash flow statement shows this relationship clearly. When inventory levels rise, cash drops. When you sell goods and reduce inventory, cash increases. This balance appears in your financial reports and helps you see how inventory decisions impact your business’s liquidity.

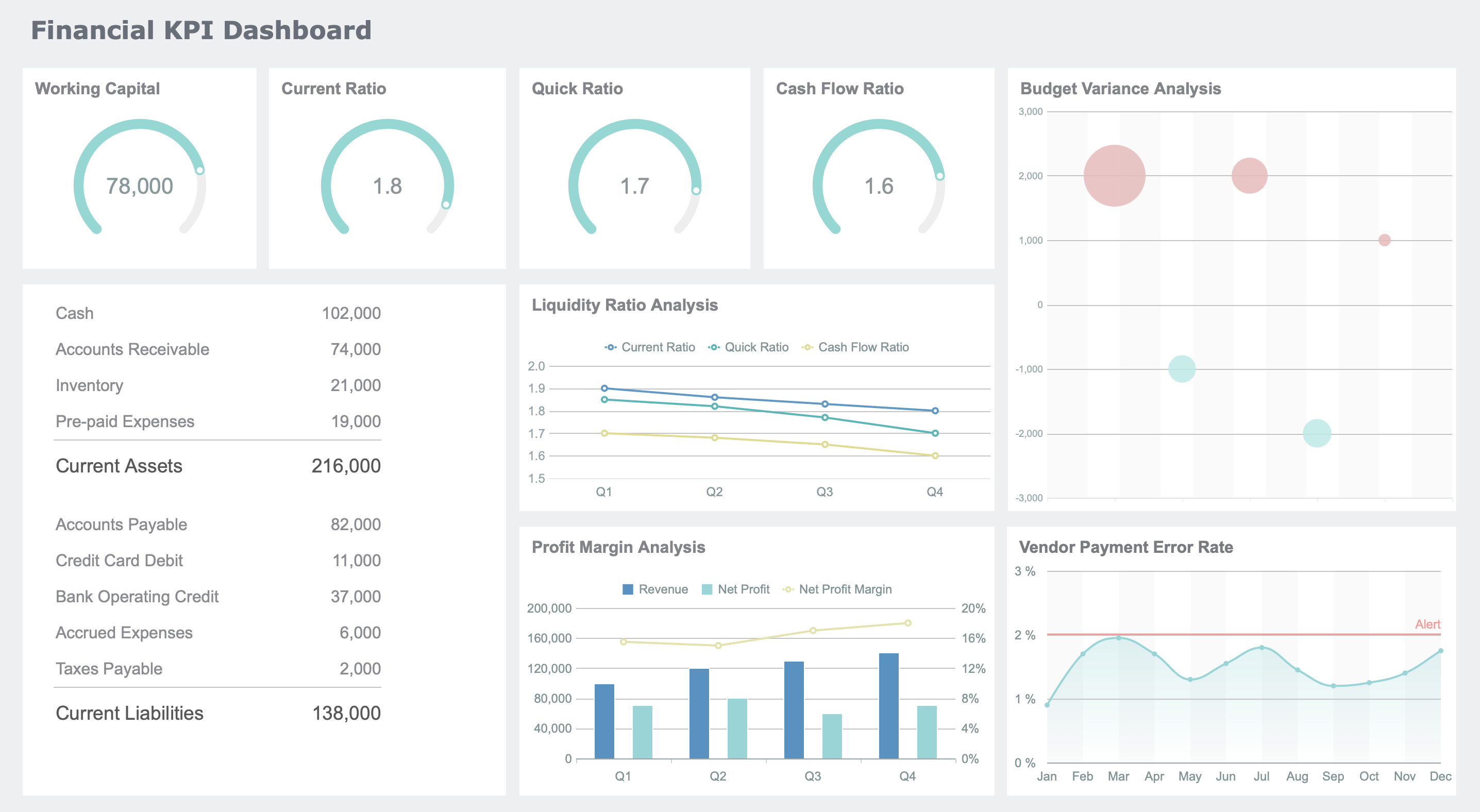

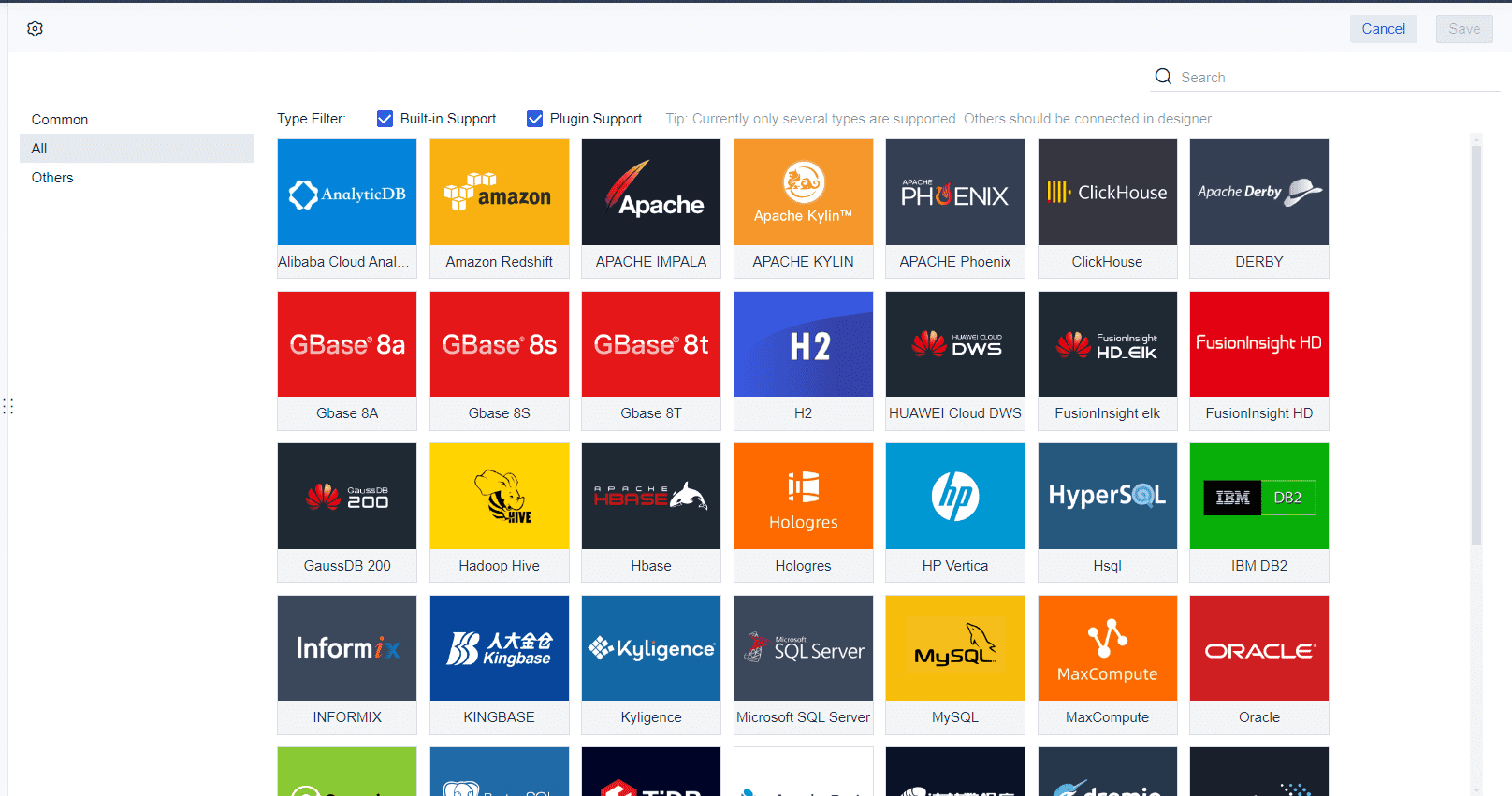

Inventory management also influences cash outflows and inflows. Buying stock is not a fixed expense. You must plan purchases to avoid cash shortages. Regularly reviewing your cash flow statement and working capital helps you spot trends and make better decisions. FineReport from FanRuan gives you real-time dashboards and analytics. You can track inventory levels, sales, and cash flow together. This visibility helps you keep your business in Malaysia stable and ready for growth.

Inventory management plays a key role in controlling costs. When you use strong stock control, you lower storage expenses and avoid overstocking. You also reduce the risk of stockouts, which can lead to lost sales. Key performance indicators like operating expense ratio, cost per unit, and employee productivity show how well you manage costs. Tracking these KPIs helps you spot problems early and take action.

You can use inventory control systems to optimize resources and improve product availability. Technologies like ERP and warehouse management systems help you forecast demand and coordinate orders. FineReport supports these efforts by providing real-time KPI tracking and detailed reports. You can see which products move quickly and which ones do not. This insight lets you adjust inventory and avoid excess or insufficient stock. Regular performance reviews and continuous improvement keep your cost savings sustainable. Embedding cost control into your company culture in Malaysia encourages everyone to look for ways to save money and work smarter.

Meeting customer demand depends on accurate inventory management. You must keep the right products available at the right time. Consumer behavior changes quickly. People want personalized products, eco-friendly options, and fast service. Flexible manufacturing and modular production help you respond to these needs. Using traceability technologies and real-time tracking improves supply chain visibility and responsiveness.

You can use demand forecasting and inventory planning to predict what customers want. Real-time inventory tracking ensures product availability and prevents stock discrepancies. Procurement processes must align with demand forecasts to keep shelves stocked. Inventory optimization strategies, like just-in-time, balance cost efficiency with product availability.

| Component | Description | Impact on Meeting Customer Demand |

|---|---|---|

| Demand Forecasting | Predicts future demand using data and analytics | Reduces stockouts and improves availability |

| Inventory Planning | Decides how much to order and when | Optimizes stock levels and avoids overstocking |

| Inventory Tracking & Control | Monitors inventory in real time | Ensures product availability and accuracy |

| Procurement | Manages supplier relationships and orders | Keeps inventory aligned with demand |

| Inventory Optimization | Uses strategies to reduce costs and increase turnover | Maintains product availability and efficiency |

FineReport helps you collect and analyze demand data. You can update forecasts often and use multiple methods to stay flexible. The platform supports contingency planning, so you can handle supply chain disruptions and keep products available. Real-time dashboards let you monitor inventory and respond quickly to changes in customer demand in Malaysia.

Inventory management supports business growth in Malaysia by improving efficiency and customer satisfaction. Advanced stock control gives you insights into sales, turnover, and consumer behavior. Using planning tools helps you forecast demand, reduce stockouts, and optimize ordering. You can lower deadstock and spoilage, which means less waste and more profit.

Growth metrics like inventory turnover ratio, inventory accuracy, and perfect order rate show how well you manage inventory. High inventory turnover means you sell and replace stock quickly. Accurate records ensure smooth operations and reduce errors. ABC inventory analysis helps you focus on high-value items and prevent shortages or overstocking.

| Growth Metric | Description | Growth Impact |

|---|---|---|

| Inventory Turnover Ratio | Measures how quickly you sell and replace inventory | Supports sustainable growth and frees up capital |

| Inventory Accuracy | Shows how well records match actual stock | Reduces errors and losses, improves reliability |

| Perfect Order Rate | Percentage of orders shipped without issues | Boosts customer satisfaction and efficiency |

| Inventory Carrying Cost | Costs of storing inventory | Lower costs mean more funds for growth |

| Customer Satisfaction Score | Measures customer happiness | Drives repeat business and positive reputation |

| Fill Rate | Measures order fulfillment accuracy | Ensures product availability and supports growth |

You can use FineReport to track these KPIs and analyze trends. The platform empowers your team to make data-driven decisions. Strong data governance and open communication help you use inventory data for continuous improvement. As you refine your inventory control processes, you support business expansion and long-term success in Malaysia.

Note: Effective stock management is not just about counting products. It is about using real-time data, analytics, and smart tools like FineReport to drive profitability, customer satisfaction, and operational excellence. When you focus on inventory management, you build a foundation for growth and resilience.

You may start with manual inventory management because it feels simple and familiar. You count items by hand and record numbers on paper or spreadsheets. This approach works for small businesses in Malaysia, but it often leads to errors, lost data, and slow updates. Manual stock control makes it hard to track inventory in real time. As your business in Malaysia grows, you may notice more mistakes and wasted time.

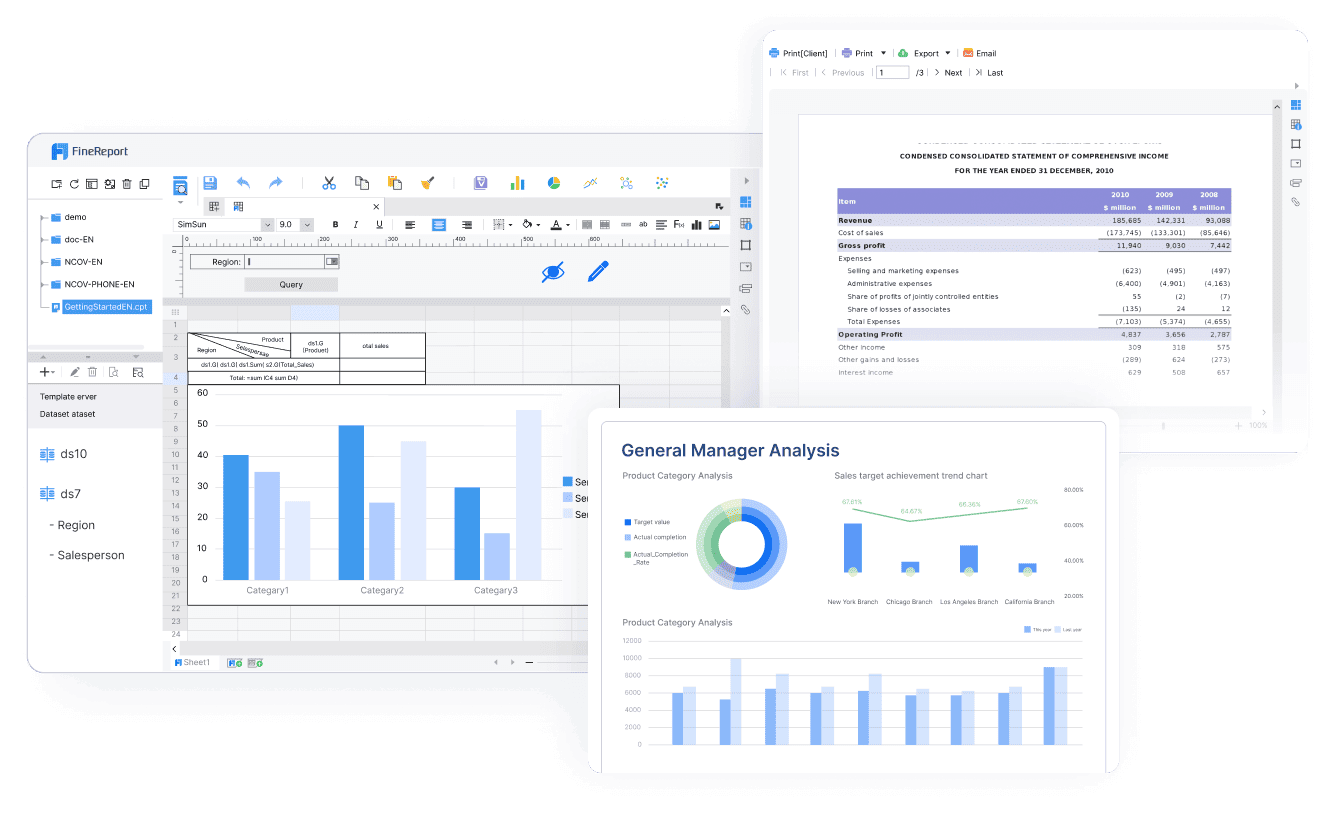

Digital inventory management changes the game. Automated systems use barcodes, cloud software, and real-time dashboards. You get instant updates on stock levels and can reorder products quickly. Digital tools help you avoid stockouts and overstocking. They also support forecasting and centralized management across locations. You reduce labor costs and improve accuracy. Many companies now use AI and IoT to monitor inventory and automate replenishment. These technologies help you adapt to market changes and support efficient inventory management.

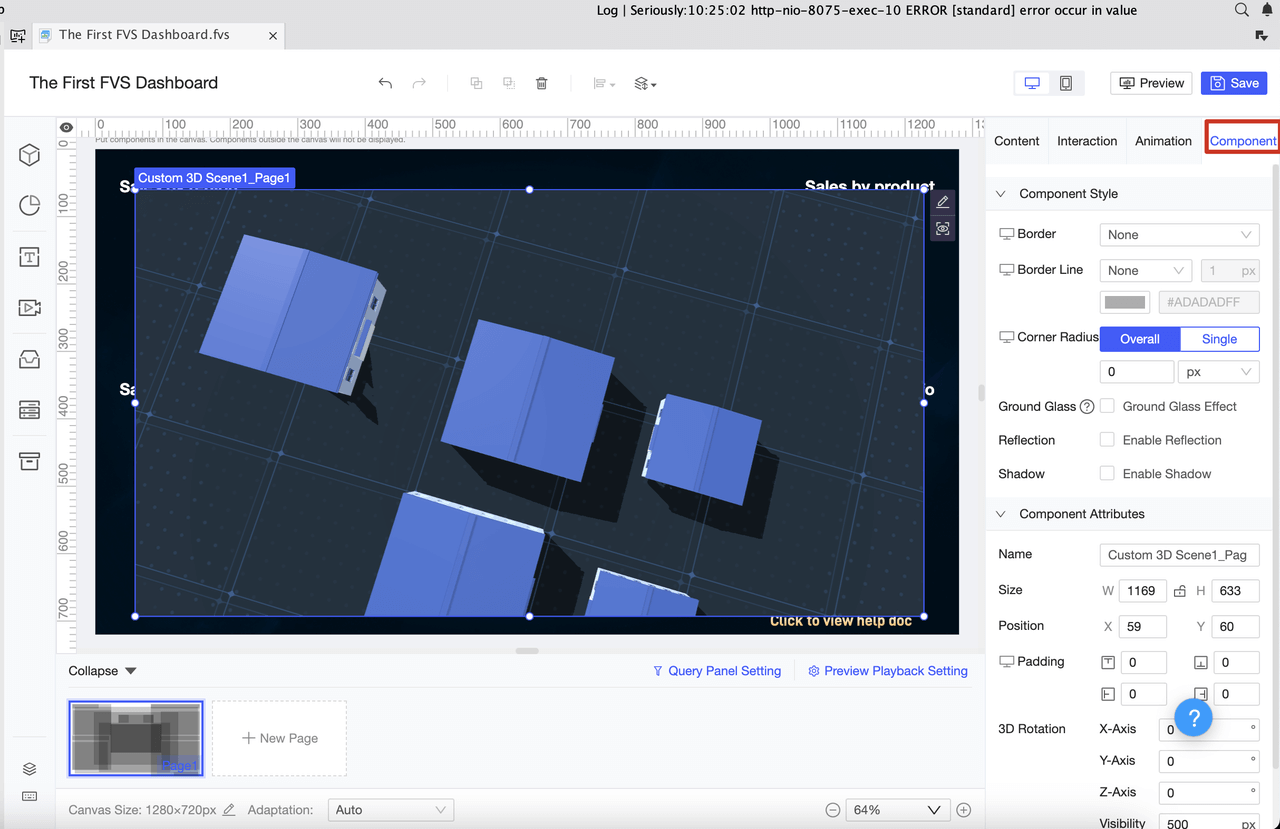

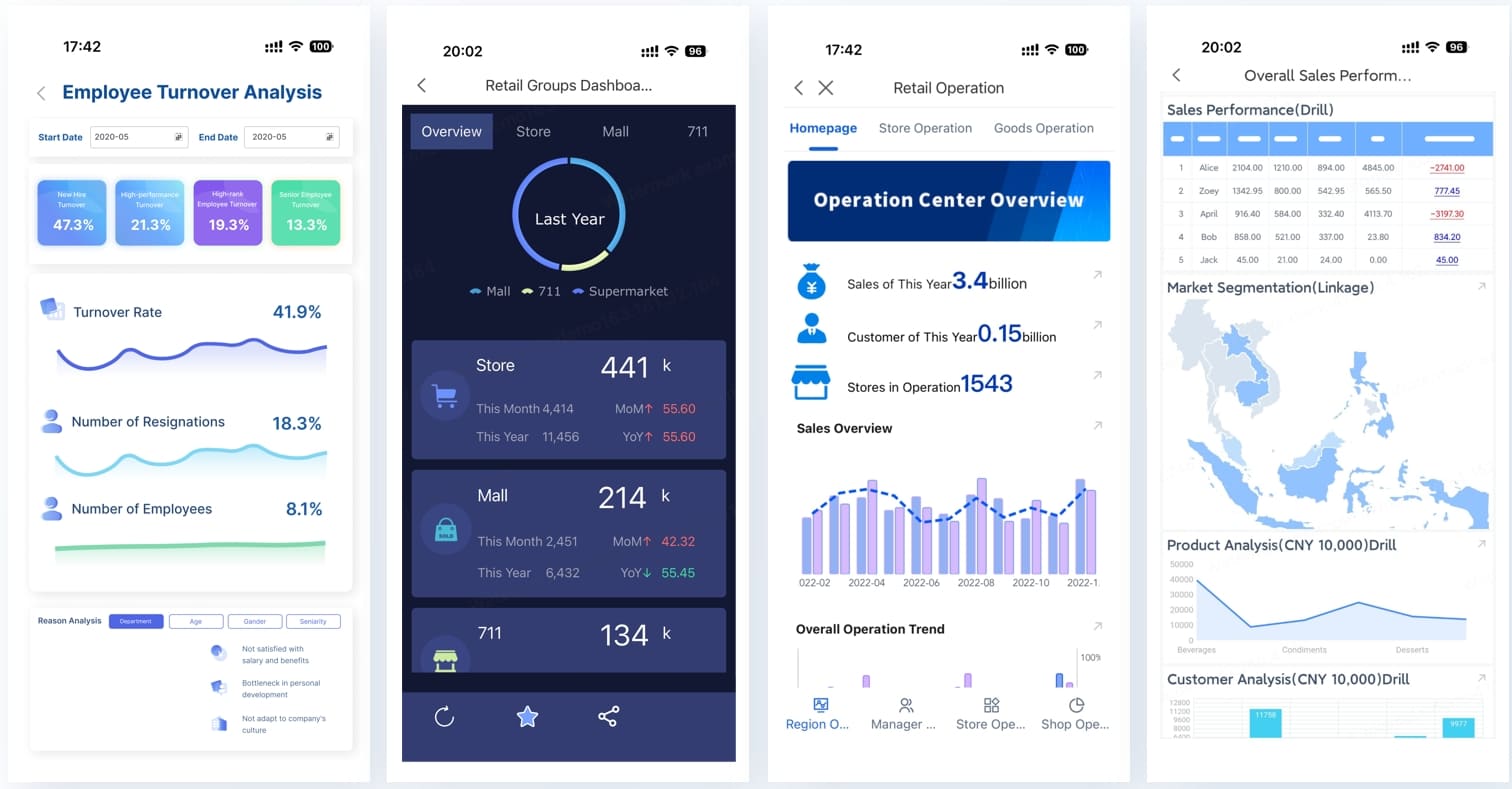

FineReport by FanRuan gives you a powerful digital solution for inventory management. You can connect data from multiple sources and view everything in one place. FineReport automates reporting and provides real-time dashboards. You track stock control, sales, and warehouse operations with ease. The platform supports mobile access, so you can check inventory on the go. FineReport helps you make data-driven decisions and improves planning. You can spot trends, reduce waste, and boost customer satisfaction.

You can use a stock change analysis dashboard to monitor inventory movements. This tool shows you which items move quickly and which stay on shelves. You identify trends and adjust your stock control strategy. The dashboard helps you reduce excess inventory and avoid shortages.

Stock structure analysis lets you see how your inventory breaks down by category or value. You focus on high-value items and manage slow movers better. This analysis supports improving planning and helps you allocate resources wisely.

A stock turnover dashboard tracks how fast you sell and replace inventory. High turnover means you use your stock efficiently. You can set goals and measure progress. This dashboard supports efficient inventory management and helps you grow your business in Malaysia.

Tip: Adopting digital tools like FineReport and following best practices can transform your inventory management. You gain better visibility, reduce errors, and support business growth in Malaysia.

Effective stock management shapes your business success in Malaysia. When you use modern tools like FineReport from FanRuan, you gain real-time insights and automate key tasks. These solutions help you:

Upgrading your stock management process gives you a strong edge, improves customer satisfaction, and supports steady growth.

Click the banner below to try FineReport for free and empower your enterprise to transform data into productivity!

Understanding Retail Management for the Modern Era

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

What is a data management platform in 2025

A data management platform in 2025 centralizes, organizes, and activates business data, enabling smarter decisions and real-time insights across industries.

Howard

Dec 22, 2025

Top 10 Database Management Tools for 2025

See the top 10 database management tools for 2025, comparing features, security, and scalability to help you choose the right solution for your business.

Howard

Dec 17, 2025

Best Data Lake Vendors For Enterprise Needs

Compare top data lake vendors for enterprise needs. See which platforms offer the best scalability, integration, and security for your business.

Howard

Dec 07, 2025