Imagine you manage a busy manufacturing plant in Malaysia. One equipment failure could cost thousands every minute, and unplanned downtime eats away at your productivity. You need maintenance reporting that is clear, actionable, and focused on results. A strong maintenance report helps you avoid costly surprises and extend equipment life. Companies in Malaysia using structured, data-driven reports have seen equipment maintenance costs drop and productivity rise. FineReport empowers you to achieve better maintenance reporting, making it easier to understand the importance of a maintenance report and act before problems grow.

Key Takeaways

- Start your maintenance report with clear goals to guide your team in Malaysia and focus on results.

- Include detailed descriptions, accurate data, and actionable recommendations to improve equipment care.

- Organize your report with clear sections and simple language to make it easy to understand and act on.

- Assign responsibility and deadlines for each task to ensure follow-through and better performance.

- Use tools like FineReport to automate reporting, centralize data, and support real-time decision-making.

Maintenance Report Essentials

Key Elements

A high-impact maintenance report starts with clear objectives. You need to define what you want to achieve, whether it is reducing maintenance costs, improving equipment reliability, or supporting a new maintenance strategy. Detailed descriptions of the issue, work performed, and outcomes provide the foundation for effective analysis. Including accurate data—such as downtime, parts replaced, and labor hours—enables you to identify trends and make informed decisions. Actionable recommendations, based on evidence and aligned with your maintenance strategy, guide your team in Malaysia toward continuous improvement.

Industry leaders recommend developing Standard Operating Procedures (SOPs), using real-time data collection, and tracking key metrics like Overall Equipment Effectiveness (OEE). These practices ensure your maintenance reporting in Malaysia supports predictive maintenance and operational efficiency.

FineReport by FanRuan streamlines this process. You can centralize data, automate report generation, and integrate real-time analysis, making your maintenance report both comprehensive and actionable in Malaysia.

Structure and Clarity

Organizing your maintenance report with a logical structure ensures clarity and actionability in Malaysia. Use sections such as Executive Summary, Introduction, Findings, and Recommendations. This approach helps readers quickly grasp the main points and understand the next steps. Tables and data visualizations make complex information easy to interpret.

| Section | Purpose |

|---|---|

| Executive Summary | Highlights key findings and actions |

| Introduction | Sets context and objectives |

| Findings | Details issues, data, and analysis |

| Recommendations | Outlines actionable steps for improvement |

Clear language and minimal jargon improve understanding for all stakeholders. FineReport’s intuitive design tools help you create structured, visually engaging reports that drive results in Malaysia.

Accountability and Context

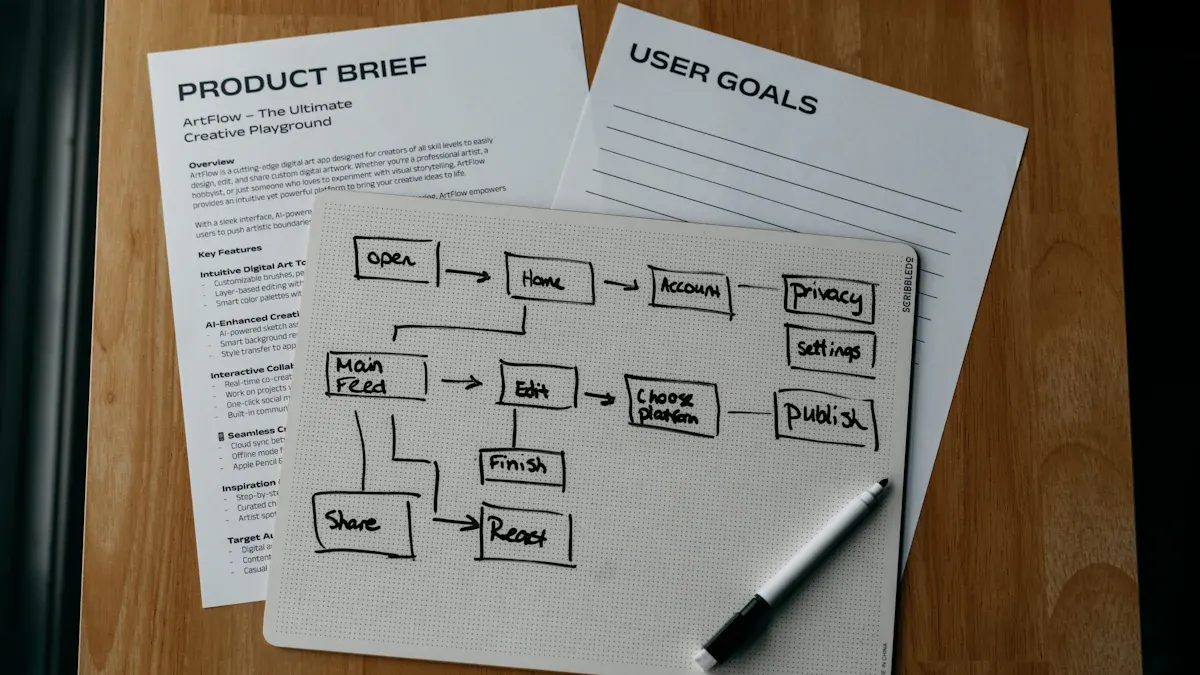

Assigning responsibility for each action item in your maintenance report ensures follow-through. Specify who will complete each task and set realistic deadlines. Context matters—align accountability with the complexity of the maintenance strategy and equipment maintenance tasks. Regular follow-up, documentation, and communication keep your team in Malaysia on track and support effective corrective actions.

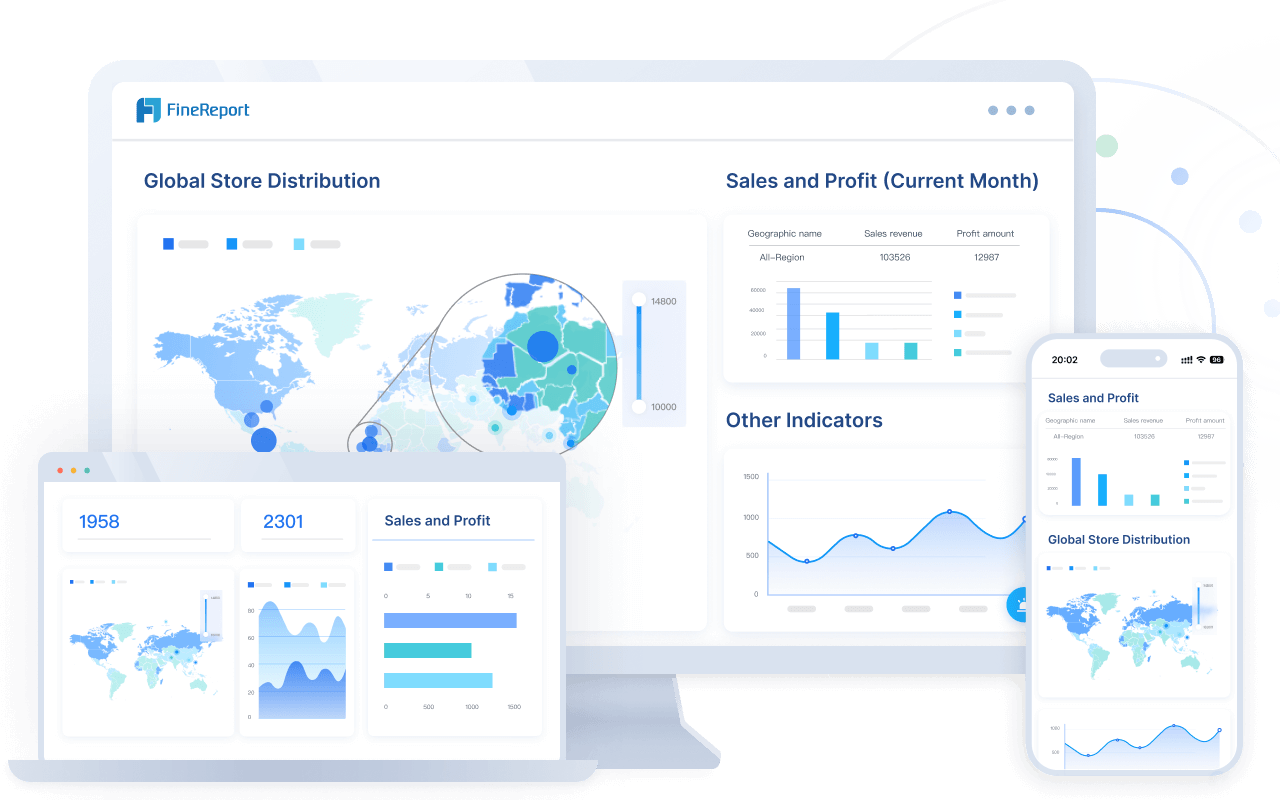

Research shows that combining accountability with context leads to better performance and fewer missed actions. FineReport’s workflow features allow you to assign tasks, monitor progress, and document every step, supporting a culture of accountability and continuous improvement in Malaysia. Here is an interactive dashoboard created by FineReport, click to experience it.

Writing a Maintenance Report

Step-by-Step Process

Writing a maintenance report that drives action starts with a clear plan. You need to capture every detail, from the initial problem to the final resolution. Follow these steps to ensure your report delivers results:

- Define the Objective

Begin by stating the purpose of the maintenance report. Are you documenting a routine inspection, an emergency repair, or a preventive maintenance task? Clear objectives help your team in Malaysia understand the report’s focus. - Describe the Issue

Provide a concise summary of the equipment problem. Include when and where the issue occurred. Use specific terms to avoid confusion. - Document Maintenance Tasks

List each maintenance task performed. Specify the tools, parts, and personnel involved. Record the start and end times for each activity. - Analyze the Root Cause

Conduct a root cause analysis to determine why the issue happened. Use data and observations to support your findings in Malaysia. This step prevents repeat failures and supports continuous improvement. - Summarize Results and Recommendations

Present the outcomes of the maintenance work. Did the repair restore normal operations? Offer actionable recommendations for future maintenance or process changes. - Assign Accountability

Identify who is responsible for follow-up actions. Set deadlines and track progress to ensure completion.

Tip: Use tables and checklists to organize information. Visual aids make your maintenance report easier to read and understand in Malaysia.

Tips for Accuracy

Accurate maintenance reports build trust and support better maintenance reporting. You must verify every detail before submitting your report. Audit best practices recommend checking data completeness, validating report logic, and documenting every procedure. These steps ensure your report is reliable and that data transformations do not compromise integrity.

Apply statistical tools such as failure distribution analysis and reliability modeling. These methods help you understand failure rates and timing. Calculate metrics like mean time between failures (MTBF) and mean time to repair (MTTR) to assess asset performance. Use these insights to refine your maintenance strategy and support root cause analysis.

Keep your records organized. Store supporting documents, photos, and data logs in a central location. Consistent documentation makes it easier to track trends and perform root cause analysis in the future.

Note: Always double-check your entries. Even small errors can lead to incorrect conclusions and missed opportunities for improvement.

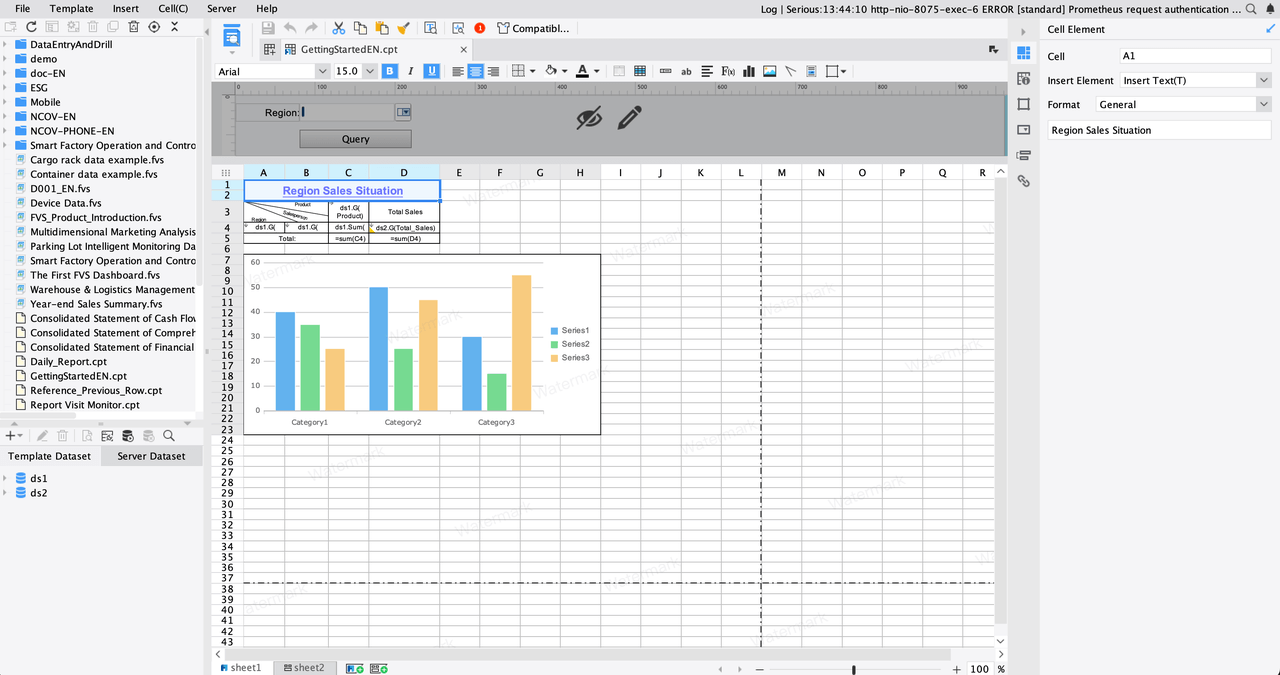

Using FineReport

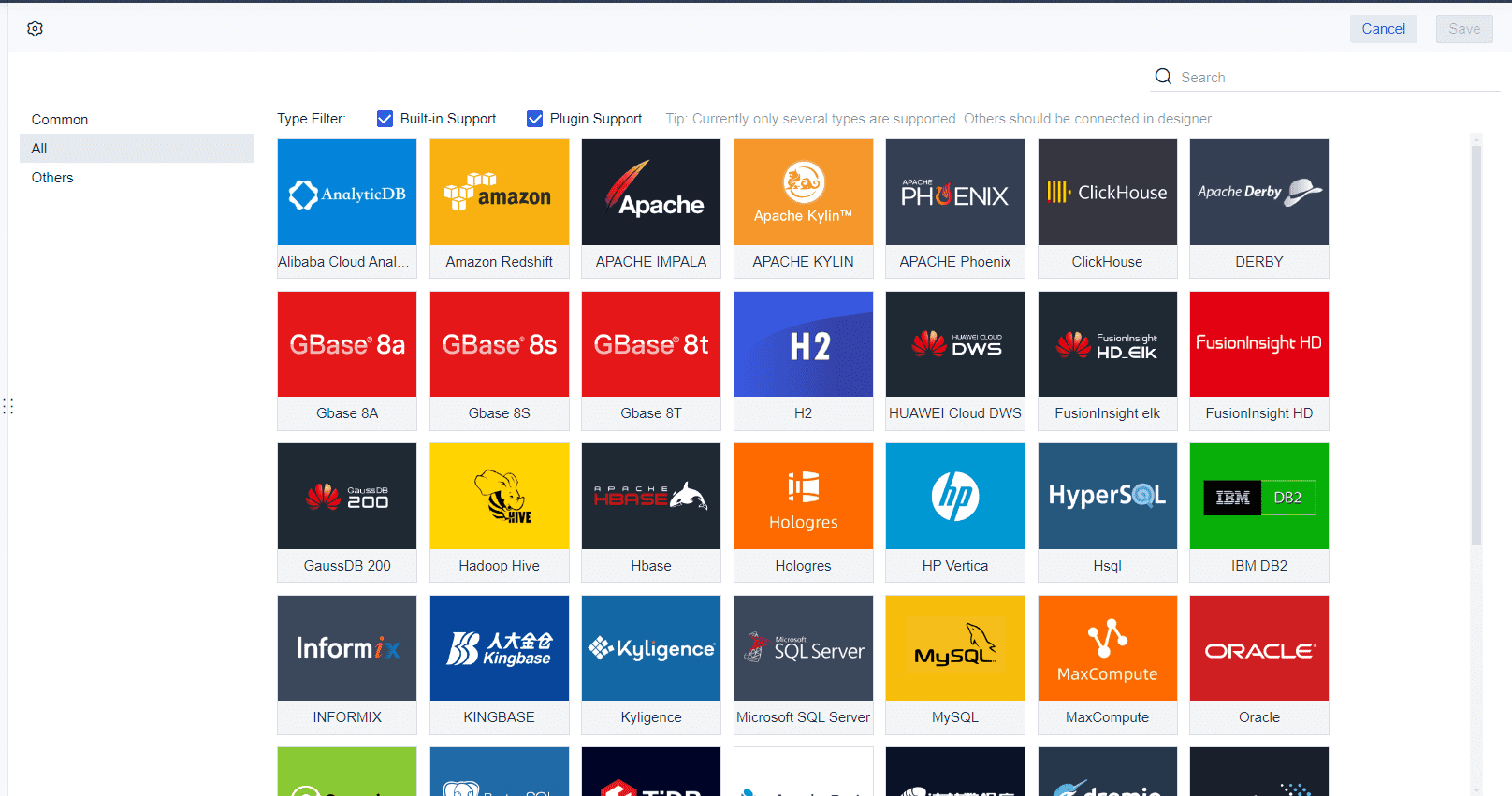

FineReport transforms how you generate maintenance reports. The platform streamlines report creation with an intuitive drag-and-drop interface. You can connect to multiple data sources, ensuring that your maintenance report includes the most current and accurate information.

FineReport enables you to automate maintenance reporting. Schedule regular reports and distribute them automatically to stakeholders. Real-time data integration keeps your team in Malaysia updated on equipment status and maintenance tasks. Mobile access allows you to review and submit reports from anywhere, supporting fast decision-making in Malaysia.

The software supports advanced analytics and visualization. You can perform root cause analysis directly within your reports, using built-in charts and dashboards. FineReport’s maintenance management software centralizes all your maintenance data, making it easy to track performance, spot trends, and take action.

With FineReport, you can automate maintenance reporting, reduce manual work, and focus on improving equipment reliability. This approach leads to faster response times and more effective maintenance strategies.

Maintenance Report Templates and Checklists

Maintenance Templates Overview

Standardized maintenance templates bring order and clarity to your maintenance program. You use these templates to ensure every technician follows the same process, reducing ambiguity and errors. Maintenance templates provide step-by-step instructions, making it easy to record tasks, parts used, and time spent. Digital templates allow you to automate workflows and update records in real time. This approach improves data quality and helps you track maintenance activities across your facility in Malaysia.

| Template Name | Purpose and Benefits |

|---|---|

| Maintenance Report Time Spend | Tracks work performed and ensures complete equipment care. |

| Maintenance Dashboard Snapshot | Presents asset status, faults, and report status for quick review. |

| Preventive Maintenance Report | Monitors costs, time, and status of preventive maintenance for better transparency. |

| Cybersecurity Maintenance Checklist | Tracks both hardware and software maintenance, improving overall reliability. |

Templates like these make your maintenance program more organized and actionable. You can quickly identify trends and address issues before they escalate.

Preventive Maintenance Checklists

Preventive maintenance checklists play a vital role in keeping your equipment running smoothly. You use these checklists to guide technicians through inspections and servicing, ensuring no steps are missed. Research shows that 89% of asset failures happen randomly, but regular use of preventive maintenance checklists reduces unplanned downtime and improves safety. These checklists also help you document your maintenance schedule, making it easier to plan and communicate tasks.

- Preventive maintenance checklists eliminate unnecessary work, letting your team in Malaysia focus on what matters most.

- They improve teamwork by clarifying responsibilities and preventing duplicated efforts.

- Regular use of checklists supports a safer workplace and extends equipment life.

A well-designed maintenance schedule, supported by checklists, keeps your maintenance program efficient and reliable.

Customization with FineReport

FineReport gives you the flexibility to create and customize maintenance templates and preventive maintenance checklists tailored to your equipment and processes. You can design digital forms that match your workflow, automate data collection, and integrate with your maintenance schedule. FineReport’s drag-and-drop interface makes it easy to update templates as your needs change. You can also set up automated reminders for each maintenance task, ensuring your team in Malaysia never misses a scheduled inspection.

With FineReport, you centralize all your maintenance templates and checklists in one platform. This approach streamlines your maintenance program, improves reporting accuracy, and supports continuous improvement in equipment management. To learn more about the FineReport features, you can click on the button below to go to the product guide.

Maintenance Report for Manufacturing

Real-Time Data Integration

You need real-time data integration to keep your manufacturing operations running smoothly. When you connect IoT sensors, equipment logs, and maintenance history, you gain instant insights into your equipment maintenance. This approach allows you to spot issues as soon as they arise and adjust your maintenance schedule before problems escalate. Real-time analysis supports predictive maintenance, helping you reduce unplanned downtime and extend machinery lifespan. Studies show that manufacturers using real-time data integration make faster decisions, improve operational efficiency, and achieve higher profit margins. You can use these insights to optimize your maintenance program and respond quickly to changing conditions.

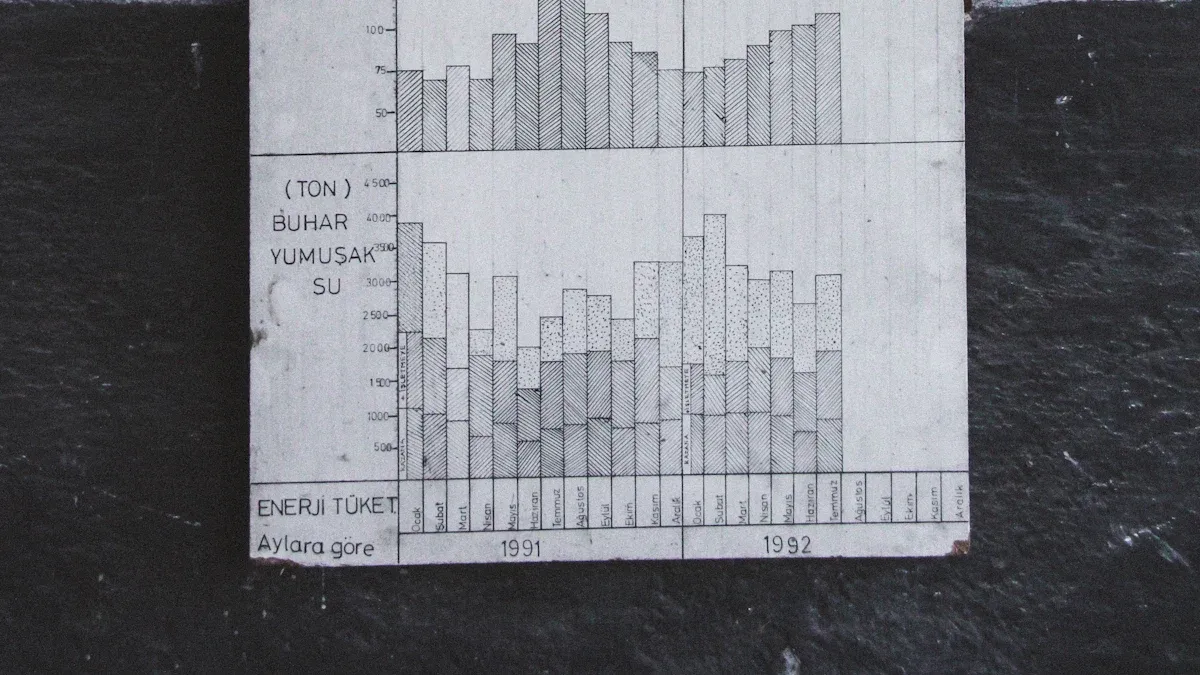

Performance Analysis

Performance analysis forms the backbone of effective maintenance reporting. You track key metrics like Mean Time Between Failure (MTBF), Mean Time To Repair (MTTR), and Overall Equipment Effectiveness (OEE) to measure equipment reliability and the success of your maintenance strategy. The table below highlights how these metrics and practices drive improvements:

| KPI/Practice | Description | Impact on Reliability |

|---|---|---|

| MTBF | Average time between equipment failures; guides preventive maintenance schedule. | Reduces downtime and avoids over-maintenance. |

| OEE | Measures availability, performance, and quality of equipment. | Identifies areas for productivity and reliability improvements. |

| Preventive Maintenance | Regular maintenance to reduce asset downtime and extend lifespan. | Lowers likelihood of unexpected failures. |

| Root Cause Analysis | Investigates underlying causes of failures to prevent recurrence. | Enables targeted corrective actions and long-term reliability. |

You use analysis to identify trends, perform root cause analysis, and refine your maintenance strategy. This process ensures your maintenance reporting leads to measurable improvements in reliability and efficiency.

FanRuan Solutions

FanRuan and FineReport empower you to take your maintenance reporting to the next level. You can centralize all your maintenance data, automate your maintenance schedule, and perform advanced analysis with ease. FineReport’s platform lets you visualize trends, assign accountability, and document every maintenance task. You gain the ability to perform root cause analysis directly within your reports, supporting a proactive maintenance approach. With FineReport, you optimize your maintenance strategy, reduce maintenance costs, and ensure your equipment maintenance program delivers results.

You can achieve better maintenance outcomes by following a structured approach to maintenance reporting. Use clear objectives, detailed documentation, and actionable recommendations. FineReport helps you centralize data and automate reporting, making your process more efficient. Organizations that use data-driven decision making see up to 30% productivity gains, fewer defects, and higher customer satisfaction.

- Real-time KPI tracking helps you spot issues early.

- Visual dashboards and regular reviews support continuous improvement.

Adopt templates and checklists, and let data guide your path to operational excellence.

Click the banner below to try FineReport for free and empower your enterprise to transform data into productivity!

Continue Reading About Report

Empower Your Business: Best Financial Reporting Tools 2025

Free Daily Report Template – Streamline Reporting Fast

What Is a Daily Report and Why Does It Matter for Businesses

What is a Monthly Report and Why Does It Matter

FAQ

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

What is integrated reporting and why is it important

Integrated reporting combines financial and non-financial data, offering a full view of value creation, transparency, and stakeholder trust.

Lewis

Dec 12, 2025

What Is a Weekly Sales Report and Why Does It Matter

A weekly sales report tracks sales data, highlights trends, and guides decisions. See key components and benefits of weekly sales reports for your team.

Lewis

Dec 11, 2025

Top 9 Best Reporting Tools for ASP.NET Developers

Compare the top 9 best reporting tool for asp net projects in 2026. Find features, integration, and export options for ASP.NET and ASP.NET Core apps.

Lewis

Dec 10, 2025