Manufacturing engineering shapes the way you design, improve, and manage production processes. In today’s factories in Malaysia, you see a surge of digital tools and smart systems.

Statistics show that the digital economy’s share of GDP in China climbed from 30% to 36.2% between 2016 and 2019. This rapid growth proves how digital technology boosts manufacturing engineering and strengthens the global economy.

You can think of manufacturing engineering as the design and operation of complex, dynamic systems that optimize how materials, energy, and information flow through a factory. This field goes beyond using single machines or tools. Instead, you use a system-level approach that connects procedures, devices, and data. You focus on creating a process network that keeps production stable, efficient, and safe. By combining innovation, technology, and teamwork, you help factories in Malaysia run smoothly and adapt to new challenges.

As a manufacturing engineer in Malaysia, you play a central role in modern production. Your main functions include:

Tip: Your ability to connect people, processes, and technology makes you a key driver of manufacturing success in Malaysia.

To succeed in manufacturing engineering, you need a mix of technical and soft skills. Here are some of the most important ones:

| Key Manufacturing Engineering Skill | Example or Assessment Method |

|---|---|

| CAD Software Proficiency | Design and modify drawings using AutoCAD, SolidWorks, or CATIA. |

| Process Optimization | Spot inefficiencies and suggest improvements. |

| Material Science | Choose materials for durability and cost. |

| Quality Control | Use inspection techniques and ISO standards. |

| Lean Manufacturing | Apply Kaizen, 5S, and value stream mapping. |

| Project Management | Plan and lead projects with Gantt charts or Agile tools. |

| Automation Systems | Design and manage automated systems. |

| Statistical Analysis | Analyze data to improve processes. |

| Technical Documentation | Write clear manuals and reports. |

You also need strong communication, teamwork, and leadership skills. You must adapt to new technologies like AI and robotics. Problem-solving, attention to detail, and a focus on continuous improvement help you stay ahead. You should also understand sustainability and risk management to support safe and eco-friendly manufacturing in Malaysia.

You shape the foundation of every factory with process design. This area focuses on planning and organizing each step in production to maximize efficiency and minimize waste. When you optimize raw material use and renegotiate supplier contracts, you can cut costs without sacrificing quality. Root cause analysis and Six Sigma methods help you reduce defects, as seen in glass plants that improved product quality by eliminating air bubbles. You also coordinate equipment and workforce to reduce downtime, which boosts productivity. Manufacturing dashboards give you real-time visibility, so you can spot bottlenecks early and make better decisions. Daily cross-team meetings improve communication, leading to fewer delays and higher output. Survey data from plants worldwide shows that effective process design increases both efficiency and innovation, especially when you tailor your approach to the competitive environment in Malaysia.

Tip: Rigorous testing, modular layouts, and sustainable practices make your factory in Malaysia more resilient and adaptable to change.

Automation transforms how you work in manufacturing engineering. You use robots, AI, and IoT devices to automate repetitive tasks and monitor equipment in Malaysia. Robotic Process Automation (RPA) runs tasks around the clock, increasing productivity and lowering labor costs. AI and machine learning analyze data and support decision-making, which reduces errors. Automated data validation processes thousands of records in seconds, saving time and money compared to manual checks. When you automate, you also scale operations easily and handle more data without extra costs. These tools help you resolve issues faster and keep your production lines in Malaysia running smoothly.

Quality control ensures that every product meets your standards. You use advanced inspection systems, such as Deep Convolutional Neural Networks, to detect defects quickly and accurately. For example, automated systems in brake caliper manufacturing achieve nearly 99% accuracy, processing images in seconds and improving energy efficiency. Machine learning models like Random Forests handle complex sensor data, making fault detection more reliable. Automated inspection stations often outperform human inspectors in speed and accuracy, which leads to better Overall Equipment Effectiveness and energy savings. By focusing on quality control, you maintain high standards and reduce waste throughout your operations in Malaysia.

You drive innovation and efficiency every day in the world of manufacturing. New technologies like artificial intelligence, IoT, and automation change how you approach production. These tools help you make smarter decisions, reduce waste, and boost productivity in Malaysia. For example, artificial intelligence now supports quality control, predictive maintenance, and resource management. You can spot problems before they cause downtime and keep your equipment running longer in Malaysia.

Many companies in Malaysia have already seen the benefits. Company ABC used IoT and AI to reorganize operations, which improved agility and collaboration. A pharmaceutical firm in Malaysia adopted predictive maintenance, cutting downtime and optimizing resources. Another manufacturer in Malaysia used VR and AR for training, which improved safety and job satisfaction. These changes show that you can achieve better results by embracing digital tools.

You also see real-world results in major industries:

| Company | Innovation Focus | Solutions Implemented | Impact |

|---|---|---|---|

| Boeing | Automation, Lean Manufacturing | Automated assembly, lean techniques | 25% less assembly time, less waste |

| Intel | Advanced Chip Manufacturing | 3D transistors, automated lines | Smaller, more powerful chips |

| Siemens | Digital Factory, AI | Digital twins, IoT integration | 30% faster time-to-market, less energy used |

| Caterpillar | Industry 4.0, IoT, AI | Robots, sensors, predictive analytics | More agility, lower costs, better quality |

You can see that manufacturing engineering leads to faster, safer, and more efficient production. By using data-driven methods and cross-team collaboration, you stay ahead of market demands and keep your operations in Malaysia running smoothly.

Note: When you use real-time monitoring and advanced analytics, you reduce downtime and improve decision-making across your factory in Malaysia.

You play a key role in building a more sustainable future in Malaysia. Manufacturing engineering now focuses on reducing environmental impact and conserving resources. You invest in new technologies and processes that use less energy and create less waste. Many companies in Malaysia work together with governments, universities, and non-profits to share knowledge and develop greener solutions.

For example, Toyota uses bioenergy and solar panels to cut waste and emissions. Airbus builds planes with lighter materials to reduce fuel use. BASF saves millions of megawatt-hours each year by integrating energy flows. These efforts show that you can make a real difference by focusing on sustainability in your daily work.

You help drive the economy forward through your work in manufacturing engineering. Your efforts reduce costs, improve quality, and increase productivity. Predictive maintenance alone can cut machine downtime by up to 50% and extend equipment life by 40%. Real-time monitoring prevents up to 75% of quality issues, saving millions in warranty claims and lost production.

| Economic Impact Aspect | Statistic / Example | Source / Year |

|---|---|---|

| Cost of unplanned downtime | $50 billion annual loss for manufacturers | Deloitte, 2021 |

| Predictive maintenance | 30-50% less downtime, 20-40% longer machine life | McKinsey, 2022 |

| Quality issue prevention | 75% of issues preventable with real-time monitoring | Quality Magazine, 2022 |

| IIoT economic value | $1.2–$3.7 trillion expected by 2025 | McKinsey Global Institute, 2021 |

| Productivity gains | 10-15% higher productivity, up to 50% less downtime | McKinsey, 2021 |

| Executive importance | 86% rate real-time analytics as very important | Deloitte, 2022 |

You also see new job opportunities as the demand for digital skills grows. The rise of Industry 4.0 means you need to learn about robotics, big data, and machine learning. You help your company stay competitive by adopting these new tools and methods.

Tip: When you use advanced analytics and automation, you not only improve your factory’s performance in Malaysia but also support economic growth and job creation in your community in Malaysia.

You see smart factories in Malaysia changing the way you manage production. With FanRuan and FineBI, you can connect machines, sensors, and systems to create a digital ecosystem. For example, Kintetsu World Express (China) built the Kintetsu Business Reporting (KBR) system using FineBI. This system brings together data from different sources and displays real-time dashboards. As a result, you improve sales efficiency and information management. At industry events like the Taiwan D Forum Smart Factory Conference, FanRuan demonstrated how AI and natural language models help you detect anomalies, forecast trends, and generate reports. Even if you do not have a technical background, you can use conversation-driven analytics to make better decisions in Malaysia.

Note: Smart factory solutions let you monitor production in real time, predict equipment issues, and respond quickly to changes.

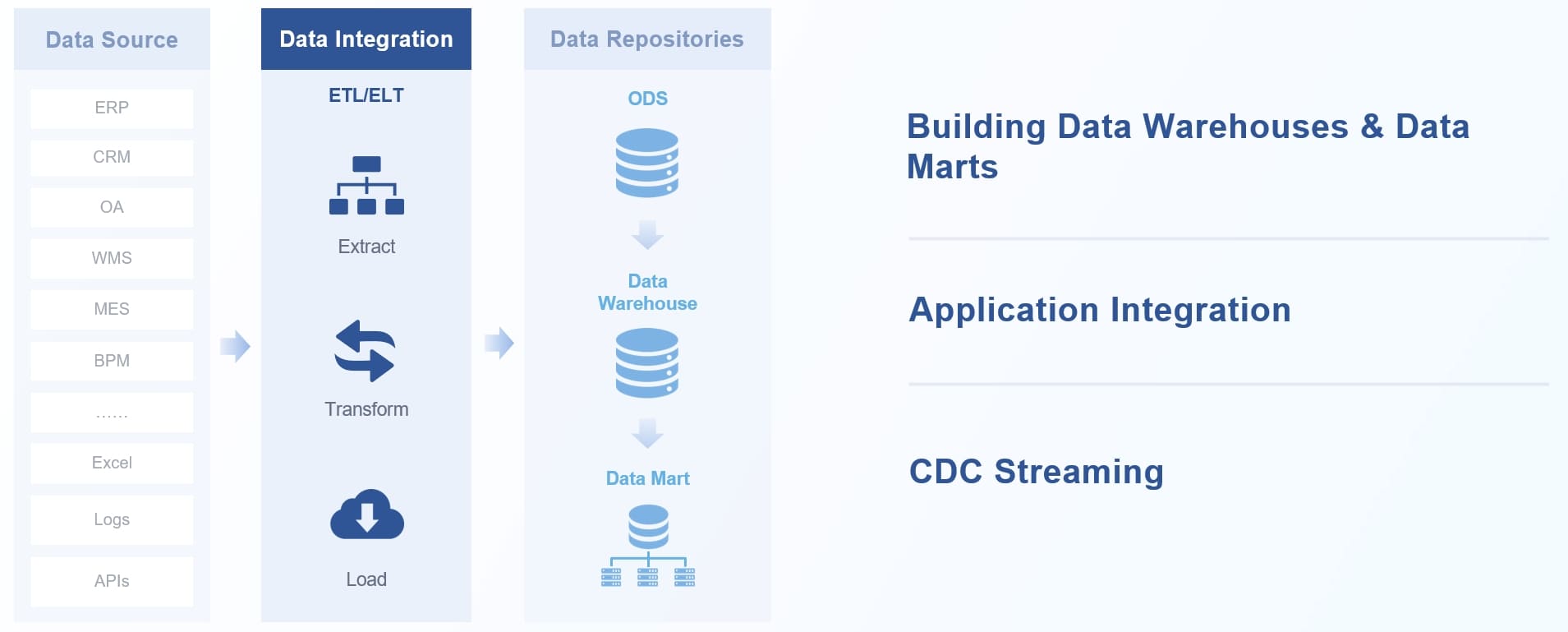

You need reliable data to make the right decisions. FanRuan’s FineDataLink acts as your core data integration tool. It connects multiple data sources, keeps your data consistent, and automates synchronization. FineBI gives you a self-service analytics platform. You can build interactive dashboards and analyze data in real time with a simple drag-and-drop interface. When you combine FineDataLink, FineBI, and FineReport, you get an end-to-end solution. FineDataLink integrates data from every department. FineBI lets you explore and visualize that data. FineReport helps you create custom reports. Many professionals earn Fanruan Certified Professional (FCP) certification to master these tools and deliver insights that drive your business in Malaysia forward.

You measure success by quality and efficiency. FanRuan and FineBI help you track key metrics like defect density, first pass yield, and return rates. For example, you might see 0.01 defects per unit for one product and 0.004 for another. First pass yield rates, such as 95% on two different lines, show how many units pass inspection without rework. You also monitor cycle times at each stage—assembly, quality control, and packaging—to spot bottlenecks. Capacity utilization rates, like 75% in one quarter and 85% in the next, reveal how well you use your resources. These insights help you reduce waste, improve product quality, and increase customer satisfaction.

| Metric | Example Value | What It Shows |

|---|---|---|

| Defect Density | 0.01 per unit | Quality issues |

| First Pass Yield | 95% | Process effectiveness |

| RMA Rate | 1% | Customer satisfaction |

| Cycle Time | 30 min (assembly) | Efficiency at each step |

| Capacity Utilization | 85% | Resource usage |

Tip: When you use these metrics, you can identify problems early and make continuous improvements across your factory in Malaysia.

You stand at the edge of a new era in manufacturing. The future brings rapid changes, driven by technology and new ways of working in Malaysia. You see artificial intelligence and generative AI becoming central to how you simulate production lines, optimize processes, and make decisions. Causal AI helps you understand cause-and-effect relationships, letting you remove bottlenecks before they slow you down. Software-driven factories now connect operations with products in the field, collecting data to improve performance.

Manufacturers in Malaysia invest heavily in digital tools. Up to 30% of operating budgets now go to cloud computing, 5G, extended reality, and AI. You notice a strong focus on data management and digital transformation. Companies in Malaysia set up AI and data governance models to support new use cases. Smart operations and manufacturing execution systems give you real-time visibility, making your factory in Malaysia more efficient.

Here are some trends shaping your future:

| Trend / Forecast | Description | Quantitative Data |

|---|---|---|

| Smart Factory Expansion | Automation and data-driven decision-making revolutionize factories | Market size to reach $321.98B by 2032, CAGR 9.52% |

| AI Adoption in Manufacturing | Smarter decisions, predictive maintenance, supply chain gains | Rapid adoption; AI now essential for advantage |

| Digital Twins & Predictive Maint | Predictive insights, less downtime, better decisions | Growing use in manufacturing |

| Workforce Evolution | Upskilling, robotics, AR/VR, human-AI collaboration | Focus on training and new tech integration |

Note: These trends show that you must adapt quickly and embrace new skills to stay ahead.

You play a vital role as technology evolves. Automation and robotics grow fast, with industrial robot sales rising by 17% each year over the last decade. These tools boost productivity, improve quality, and lower costs. You see companies bringing manufacturing back to developed regions, thanks to advanced automation. Robots handle precise, repetitive tasks, making work safer and more reliable.

You also notice that your field adapts to every wave of change. From manual tools to digital controls, you always find ways to improve efficiency and product quality. Your work drives economic growth, creates jobs, and supports global trade. In fact, manufacturing accounts for 71% of world merchandise exports. You also help balance economic, social, and environmental needs by integrating sustainability into every process.

You must keep learning and adapting. As new technologies emerge, you lead the way in building smarter, safer, and more sustainable factories.

You play a vital role in shaping the future of industry. Today’s smart manufacturing frameworks let you respond in real time to factory and supply chain changes.

You stand ready to lead innovation, sustainability, and growth in a rapidly changing world.

Click the banner below to try FineBI for free and empower your enterprise to transform data into productivity!

What is Rapid Manufacturing and How Does It Work

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

Best Self-Service Tools for Analytics You Should Know

See which self-service tools for analytics let business users access data, build dashboards, and make decisions faster—no IT help needed.

Lewis

Dec 29, 2025

Understanding Predictive Analytics Services in 2026

Predictive analytics services use data and AI to forecast trends, helping businesses make informed decisions, reduce risks, and improve efficiency in 2026.

Lewis

Dec 30, 2025

What is Distribution Analysis in Mathematics and Statistics

Distribution analysis in mathematics and statistics examines how data values spread, helping identify patterns and predict outcomes accurately.

Lewis

Dec 28, 2025