Rapid manufacturing uses digital technologies to quickly produce parts or products, often directly from computer-aided design data. You can optimize your manufacturing processes by leveraging automation, IoT, and AI to reduce waste and boost sustainability. Recent data shows 70% of UK manufacturers have faced significant cost increases, while U.S. labor costs continue to rise—pressuring you to adopt new solutions. The table below highlights how rapid manufacturing drives performance in modern manufacturing:

| Performance Metric | Improvement Range |

|---|---|

| Reduction in machine downtime | 30–50% |

| Increase in throughput | 10–30% |

| Gains in labor productivity | 15–30% |

| Improvement in forecasting accuracy | 85% increase |

You can transform your manufacturing operations in Malaysia by embracing rapid manufacturing. This approach uses digital technologies to produce parts and products directly from digital designs. You gain the ability to move from concept to finished item with remarkable speed, which is essential in today’s competitive landscape in Malaysia.

Rapid manufacturing stands out for its flexibility, cost-effectiveness, and ability to handle complex geometries and customization. You can create intricate shapes that traditional methods struggle to achieve in Malaysia. This process supports both low and medium production volumes, making it ideal for on-demand production and short-run manufacturing.

Here’s a summary of the core aspects of rapid manufacturing:

| Aspect | Summary |

|---|---|

| Definition | Enables fast production of 3D objects from digital designs, supporting flexibility and cost savings. |

| Technologies | Includes additive (3D printing) and subtractive (CNC machining, laser cutting) methods. |

| Applications | Used in aerospace, healthcare, automotive, and consumer goods for prototyping, tooling, and end-use parts. |

| Advantages | Delivers rapid prototyping, reduced time and costs, design flexibility, minimal waste, and scalability. |

| Challenges | Involves material selection, quality control, IP protection, regulatory compliance, and sustainability. |

You see rapid manufacturing gaining momentum across industries in Malaysia. Recent statistics show:

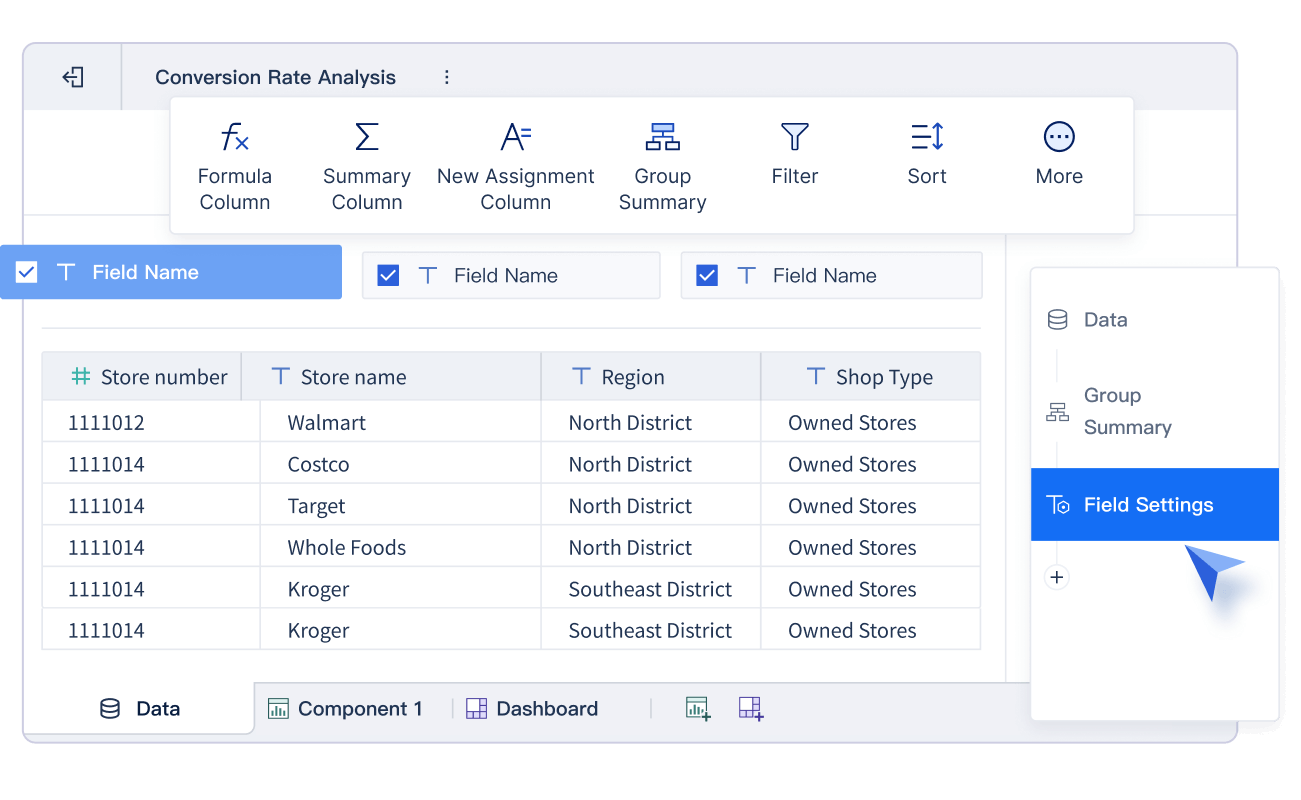

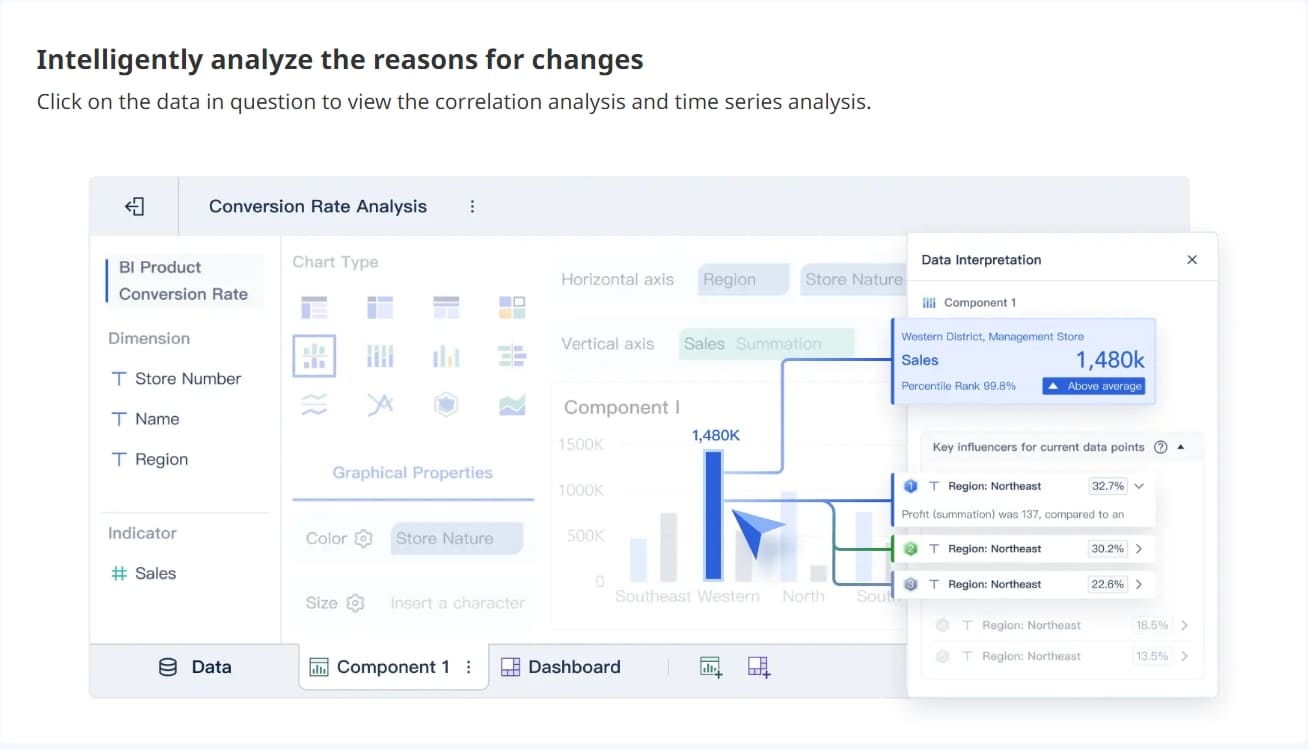

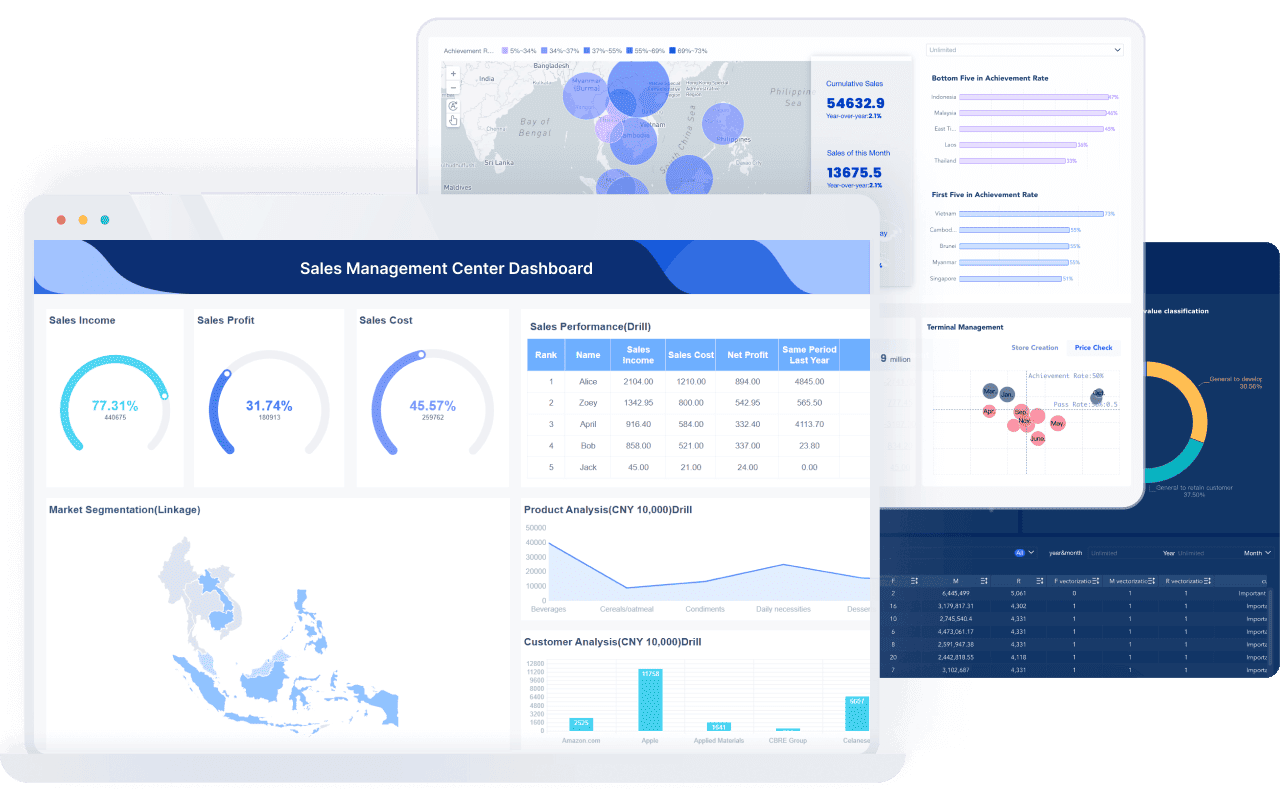

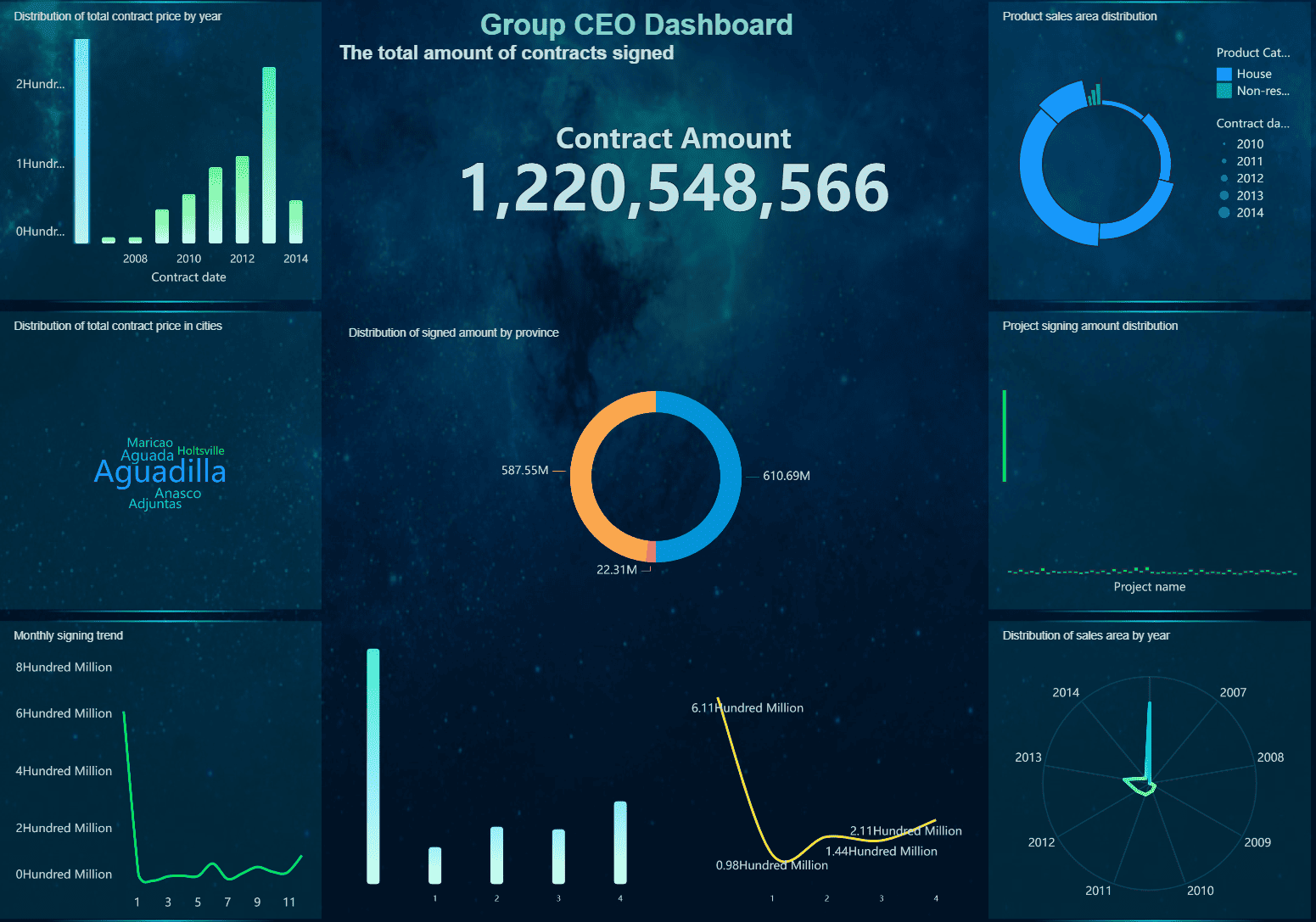

You benefit from these trends by leveraging digital platforms that integrate data from design, production, and quality control. Platforms like FanRuan and FineBI help you unify data from multiple sources, automate reporting, and gain real-time insights in Malaysia. You can use sensor data, plant floor metrics, and digital twins to optimize production, predict maintenance needs, and improve quality in Malaysia.

You might wonder how rapid prototyping differs from rapid manufacturing. Both use advanced technologies, but they serve different purposes in your workflow in Malaysia .

| Parameter | Rapid Prototyping (RP) Characteristics | Rapid Manufacturing (RM) Details |

|---|---|---|

| Process Type | Mainly additive manufacturing (SLA, FDM, SLS, LOM) | Additive (3D printing), subtractive (CNC), vacuum casting, rapid tooling |

| Purpose | Quickly produce physical models for form, fit, and function testing | Produce functional parts and small to medium production runs |

| Layer Thickness | Fine resolution for detailed models | Varies by technology and application |

| System Accuracy | High accuracy for design validation | High accuracy for end-use parts |

| Speed of Operation | Fast, enabling multiple design iterations | Up to 40% faster turnaround times than traditional methods |

| Cost Reduction | Up to 70% reduction in product development costs | 15-25% reduction in tooling costs |

| Time to Market | Up to 90% reduction in time to market | Suitable for on-demand production and short-run manufacturing |

| Production Volume | Low, focused on prototypes | Low to medium; rapid tooling extends to high volume |

| Repeatability | Focused on single or few units | Vacuum casting molds for up to 25 parts; rapid tooling for up to millions |

| Cost Efficiency | High for design validation | High for tooling and short-run production |

You use rapid prototyping to test and refine your designs. This step helps you identify flaws, improve fit, and validate function before moving to full-scale production in Malaysia. Rapid manufacturing takes you further by enabling you to produce functional parts, not just models. You can deliver finished goods directly to customers or use them in your operations in Malaysia.

Both approaches rely on digital data and advanced manufacturing methods. You can integrate CAD, CAM, and CAE systems to generate high-quality data throughout the design and production phases. With platforms like FineBI, you can connect to real-time data sources, automate analytics, and visualize key metrics. This integration supports your decision-making, quality control, and continuous improvement in Malaysia.

Tip: By combining rapid prototyping and rapid manufacturing, you can accelerate product development, reduce costs, and respond quickly to market changes in Malaysia. Digital platforms like FanRuan and FineBI give you the tools to manage data, automate workflows, and drive innovation in your manufacturing processes.

Additive manufacturing stands at the heart of rapid manufacturing. You can use these advanced processes to build parts layer by layer, directly from digital models in Malaysia. This approach lets you create complex shapes that traditional manufacturing cannot achieve. You gain speed, flexibility, and cost savings, especially when you need low to medium production volumes or custom parts.

You will find several 3D printing methods in modern manufacturing in Malaysia. Each method offers unique benefits for different applications:

Recent advancements make these additive manufacturing techniques even more powerful. Nearly all surveyed companies now use 3D printing for functional or end-use parts. About 80% produce at least 25-50% of their functional parts with additive methods. You can expect your use of 3D printing to grow, as 97% of manufacturers in Malaysia plan to expand their adoption in the next five years.

| Improvement Aspect | Description & Data Points |

|---|---|

| Layer Height Optimization | Balances print quality and speed; thicker layers reduce production time without losing surface quality |

| Automation | Cuts setup times from days to seconds; coordinates multiple machines |

| Support Structure Reduction | Minimizes waste and boosts productivity, especially in aerospace |

| Post-Processing Techniques | Enhances part quality with grinding, polishing, and painting |

| Material & Environmental | Uses recycled materials and energy-efficient printers to lower waste and impact |

You can also use other rapid manufacturing methods alongside additive manufacturing. CNC machining removes material from a solid block to create precise parts. Rapid tooling produces molds and dies quickly, supporting short-run production. Vacuum casting lets you make small batches of plastic parts with high accuracy.

Additive manufacturing techniques, combined with these methods, help you overcome the limits of traditional manufacturing in Malaysia. You can produce complex parts in a single step, reduce inventory, and respond faster to market needs. Data integration and analytics platforms like FineBI play a key role in this process. You can connect design files, monitor equipment, and track material usage in real time. FineBI helps you centralize data, automate reporting, and spot trends in quality control. This leads to fewer errors, less downtime, and better decision-making in your smart factory in Malaysia.

Tip: By using additive manufacturing and advanced analytics, you can boost efficiency, cut costs, and stay ahead in today’s competitive manufacturing landscape in Malaysia.

You start the rapid manufacturing process with digital design. Computer-aided design (CAD) software lets you create detailed 3D models of your parts or products. These digital files serve as the blueprint for every step that follows. You can easily modify designs, test different configurations, and share files across teams or locations.

To maximize efficiency, you need robust data integration. Platforms like FanRuan and FineBI help you connect design data, production metrics, and quality control information in real time. You can break down data silos and ensure every department works from the same source of truth. This integration reduces errors, speeds up decision-making, and supports automation in Malaysia.

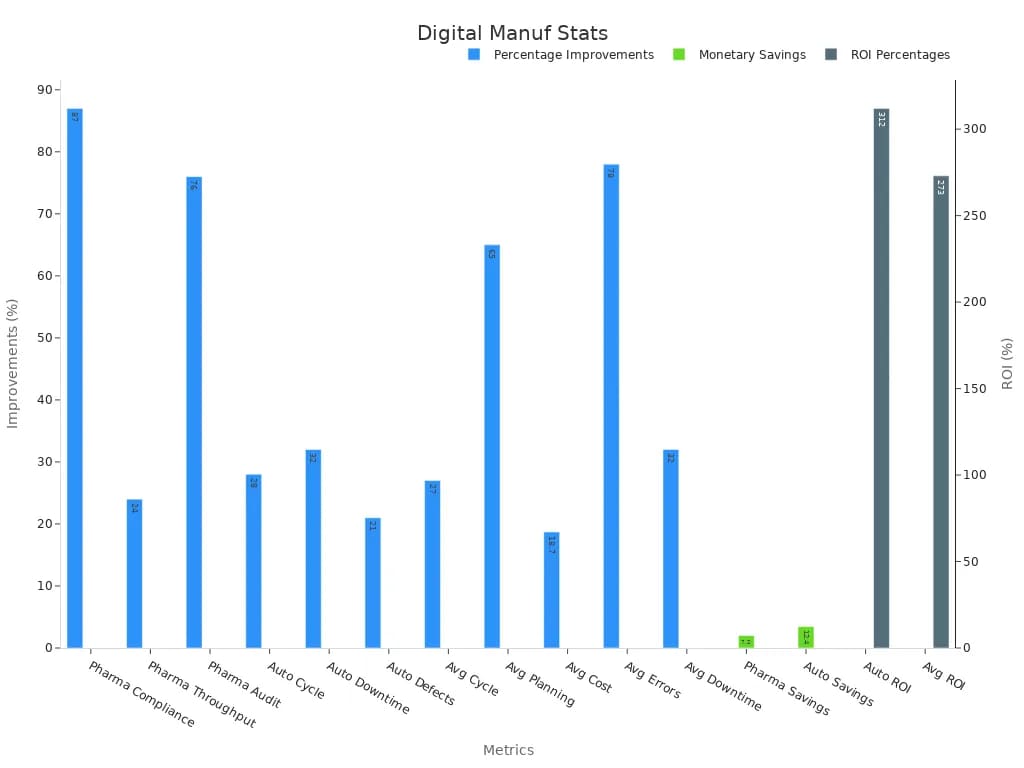

When you use integrated digital platforms, you see dramatic improvements in your manufacturing operations in Malaysia. For example, a pharmaceutical manufacturer reduced compliance reporting time by 87% and cut batch release time from 14 days to just 3 days. A global automotive supplier lowered production cycle time by 28% and unplanned downtime by 32%. These results show how digital design and data integration drive real value.

| Metric / Case Study Aspect | Result / Improvement |

|---|---|

| Pharmaceutical Manufacturer: Compliance reporting time | Reduced by 87% |

| Pharmaceutical Manufacturer: Batch release time | Decreased from 14 days to 3 days |

| Pharmaceutical Manufacturer: Manufacturing throughput | Increased by 24% without additional equipment |

| Pharmaceutical Manufacturer: Regulatory audit findings | Reduced by 76% |

| Pharmaceutical Manufacturer: Annual savings | $7.2 million |

| Global Automotive Supplier: Production cycle time | Reduced by 28% |

| Global Automotive Supplier: Unplanned downtime | Decreased by 32% |

| Global Automotive Supplier: Quality defects | Reduced by 21% |

| Global Automotive Supplier: Inventory cost savings | $12.4 million annually |

| Global Automotive Supplier: ROI | 312% over three years |

| Average production cycle time reduction | 27% |

| Average production planning time reduction | 65% |

| Average operational cost reduction | 18.7% |

| Average reduction in data errors | 78% |

| Average reduction in unplanned downtime | 32% |

| Average ROI over three years | 273% |

You can see that digital design and data integration platforms not only speed up your processes but also deliver significant cost savings and quality improvements in Malaysia.

You move from digital design to physical production through a series of well-defined steps. Here’s how the rapid manufacturing process typically unfolds:

You can use platforms like FineBI to visualize these steps, track progress, and identify bottlenecks in real time. FineBI’s dashboards let you monitor production cycles, inventory levels, and equipment status at a glance. This visibility helps you make quick adjustments and keep your manufacturing process running smoothly in Malaysia.

| Key Performance Indicator | Improvement / Outcome |

|---|---|

| Production planning time | Reduced by 65% through real-time data access |

| Automated data workflows | Minimized process delays by 42% |

| Production bottlenecks identification | 3.5 times faster via integrated data analysis |

| Operational cost reduction | 18.7% average decrease |

| Inventory management cost | Decreased by 21% |

| Predictive maintenance repair costs | Reduced by 29% |

| Energy consumption | Decreased by 14% |

| Quality control costs | Dropped by 22% |

| Data errors | Reduced by 78% |

| Decision quality improvement | Increased by 67% |

| Predictive maintenance accuracy | Increased by 73% |

| Quality control precision | Improved by 42% |

| Compliance reporting errors | Reduced by 84% |

| Unplanned downtime reduction | 32% average reduction |

| ROI | 273% average over three years |

You can see how each step in the process, when supported by real-time data and analytics, leads to measurable improvements in speed, cost, and quality.

You ensure the success of rapid manufacturing by focusing on quality control and analytics. Real-time monitoring tools let you track every stage of production in Malaysia. For example, you can use Process Analytical Technology (PAT) tools to monitor protein concentration or near-infrared spectroscopy to measure chemical composition. These tools give you instant feedback, so you can make adjustments before problems escalate.

You also benefit from advanced analytics. Statistical Process Control (SPC) charts help you spot process variations and detect anomalies early. Measurement System Analysis (MSA) ensures your measurement systems remain accurate and reliable. Root Cause Analysis (RCA) helps you find the underlying causes of faults, so you can fix issues at their source.

Platforms like FineBI empower you to centralize all your quality data, automate reporting, and share insights across your organization in Malaysia. You can set up automated alerts for deviations, track key performance indicators, and ensure every batch meets your standards. This approach supports the production of high-quality end-use parts and helps you maintain a competitive edge in the manufacturing industry in Malaysia.

Tip: By combining digital design, integrated data, and real-time analytics, you can transform your rapid manufacturing process in Malaysia. You gain speed, flexibility, and quality—delivering reliable end-use parts to your customers faster than ever before.

You see rapid manufacturing transforming industries such as automotive, aerospace, and medical devices. In Malaysia's aerospace, you can use Direct Metal Laser Fabrication to build thin-walled metal parts, saving up to 80% of machining time and reducing costs by up to 50%. In the biomedical field, you can create patient-specific devices and medical models with high dimensional accuracy, supporting better outcomes for patients. Rapid tooling allows you to produce molds quickly, with some designs seeing an 84% reduction in mold design time. These examples show how you can achieve faster turnaround, higher precision, and greater flexibility.

| Industry Sector | Case Study Description | Numerical Evidence / Outcome |

|---|---|---|

| Aviation & Aerospace | Direct Metal Laser Fabrication for metal parts | Up to 80% machining time saved; 20–50% cost reduction |

| Biomedical | Polyjet, 3DP, SLS for medical models and devices | 0.18 mm average accuracy; successful implants |

| Rapid Tooling | FDM and SLA for molds and injection tools | Mold design time reduced by 84%; tools withstood 500 cycles |

You gain several advantages of rapid manufacturing when you adopt these technologies. You can increase production output by 10% to 20% and boost employee productivity by up to 20%. Many manufacturers in Malaysia report unlocking 10% to 15% more capacity. Most believe that smart manufacturing drives competitiveness and helps attract talent. You also benefit from improved economic efficiency, lower energy use, and reduced waste. The table below highlights these improvements:

| Metric | Improvement / Percentage |

|---|---|

| Production output improvement | 10% to 20% |

| Employee productivity increase | 7% to 20% |

| Unlocked capacity increase | 10% to 15% |

| Manufacturers seeing competitiveness gains | 92% |

| Manufacturers expecting transformation and agility | 85% |

You also see positive impacts on green development and innovation. You reduce energy consumption, wastewater, and solid waste. You invest more in R&D and increase the number of valid invention patents. These changes support sustainability and long-term growth in Malaysia.

Tip: By leveraging digital integration and real-time data, you can optimize resource use, minimize waste, and improve supply chain efficiency.

You can use FanRuan and FineBI to enable real-time insights and digital transformation in your manufacturing operations in Malaysia. FineBI increases your data analysis efficiency by at least 50% compared to traditional methods. You receive real-time feedback and validation, which supports smarter decisions and faster responses to production changes.

You can analyze product sales across multiple channels and regions in Malaysia. FineBI lets you connect to various data sources, visualize trends, and identify top-performing products. You can track sales performance in real time, adjust your strategies, and respond quickly to market demand. This level of customization supports on-demand production and helps you deliver end-use parts that meet customer needs in Malaysia.

You can streamline your business operation by integrating data from design, production, and quality control. FineBI provides dashboards that show key metrics such as inventory levels, equipment status, and quality indicators. You can automate reporting, set up alerts for deviations, and ensure every department works from the same data. This approach enhances transparency, supports continuous improvement, and maximizes the advantages of rapid manufacturing.

Note: When you use FanRuan and FineBI, you build a foundation for smart manufacturing that supports efficiency, customization, and sustainable growth.

You face several challenges when you implement rapid manufacturing in your operations. Many companies report IT system maturity and integration as a major hurdle. You often need to connect new digital tools with existing systems, which can slow down progress. Process disruptions can occur, especially in assembly-intensive environments. You may find that information is not always available when you need it, making decision-making harder.

Recent studies highlight six main challenges:

You also encounter challenges with quality control, skilled labor, and regulatory compliance. Rapid manufacturing requires you to monitor process variability closely to maintain dimensional accuracy and surface finish. You need highly skilled workers in Malaysia who understand advanced equipment and software. Meeting strict industry standards in Malaysia, such as those in aerospace or healthcare, can be difficult as regulations evolve. Material selection presents another challenge, since you may have fewer options and inconsistent material quality.

Here is a comparison of key challenges:

| Aspect | Rapid Manufacturing Challenges | Traditional Manufacturing Characteristics |

|---|---|---|

| Quality Control | Process variability; needs robust monitoring | More consistent due to mature processes |

| Skilled Labor | Requires advanced skills and training | Relies on established skills, larger workforce |

| Regulatory Compliance | Adapting to evolving standards | Established compliance pathways |

| Material Selection | Limited options, inconsistent quality | Wide range, consistent quality |

| Cost and Speed | Lower cost and faster for small runs | Slower and costlier for low volume |

| Accuracy | Lower due to process limits | Higher due to precise machining |

| Material Wastage | Minimal waste | Significant waste |

Note: Many companies still rely on manual or paper-based processes, which can limit the benefits of rapid manufacturing.

You see clear differences when you compare rapid manufacturing to traditional methods. Rapid manufacturing, including rapid prototyping, gives you faster lead times and greater flexibility. You can produce custom or complex parts without the need for expensive tooling. This approach works best for low-volume or highly customized production.

Traditional manufacturing excels in high-volume production. You benefit from lower unit costs at scale, but you face longer lead times due to tooling and setup. Customization is limited and often expensive. Material waste is higher because subtractive processes remove excess material.

The table below summarizes the main differences:

| Aspect | Traditional Manufacturing | Additive Manufacturing (Rapid Manufacturing) |

|---|---|---|

| Production Volume | Best for high-volume mass production | Best for low-volume or custom parts |

| Lead Time | Longer due to tooling and setup | Shorter; no tooling required |

| Cost Efficiency | Lower per unit at scale; high initial tooling costs | Lower for small runs; less efficient at high volumes |

| Flexibility & Customization | Limited; costly to change tooling | High; easy to produce unique or complex designs |

| Waste & Sustainability | More waste from subtractive processes | Less waste; builds only what you need |

| Scalability | Scales well for mass production | Flexible; easy to scale up or down |

You can combine rapid prototyping with traditional manufacturing to optimize efficiency, cost, and scalability. This hybrid approach lets you respond quickly to market changes in Malaysia while maintaining quality and controlling costs.

You have seen how rapid manufacturing transforms your production process in Malaysia. By adopting digital solutions like FanRuan and FineBI, you gain real-time insights, streamline operations, and improve quality. You can respond faster to market changes and drive innovation. Consider rapid manufacturing as your path to future-ready operations in Malaysia.

Embrace digital integration to stay competitive and lead your industry in Malaysia.

Click the banner below to try FineBI for free and empower your enterprise to transform data into productivity!

What You Need to Know About Manufacturing in Malay

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

Best Self-Service Tools for Analytics You Should Know

See which self-service tools for analytics let business users access data, build dashboards, and make decisions faster—no IT help needed.

Lewis

Dec 29, 2025

Understanding Predictive Analytics Services in 2026

Predictive analytics services use data and AI to forecast trends, helping businesses make informed decisions, reduce risks, and improve efficiency in 2026.

Lewis

Dec 30, 2025

What is Distribution Analysis in Mathematics and Statistics

Distribution analysis in mathematics and statistics examines how data values spread, helping identify patterns and predict outcomes accurately.

Lewis

Dec 28, 2025