Predictive analytics in supply chain management lets you use data and algorithms to forecast future trends and make smarter decisions. You rely on predictive models to analyze patterns, improve demand forecasting, and optimize logistics. Predictive analytics helps you anticipate customer needs, reduce stockouts, and streamline operations. When you use predictive tools, you can track inventory, minimize risks, and boost efficiency. Many companies, especially in the pharmaceutical sector, have adopted predictive analytics to enhance supply chain management. Data-driven insights from predictive analytics improve transparency, reveal inefficiencies, and support sustainable practices.

You can use predictive analytics to improve demand forecasting and make your supply chain more responsive. With supply chain predictive analytics, you analyze past sales, market trends, and customer behavior to predict what products customers will want and when. This process helps you avoid both overstocking and running out of stock.

Many companies rely on statistical methods to boost the accuracy of demand forecasting. Here are some common techniques:

| Method | Description |

|---|---|

| Collaborative Planning, Forecasting, and Replenishment (CPFR) | You work with partners to share information and improve forecasts. |

| Delphi Method | You gather expert opinions in rounds to reach a consensus. |

| Simulation Models | You create virtual scenarios to test how different factors affect demand. |

| Exponential Smoothing | You give more weight to recent data to spot trends quickly. |

| Moving Average | You smooth out short-term spikes by averaging past data points. |

| Regression Analysis | You find relationships between variables to predict future demand. |

By using predictive analytics in supply chain management, you gain better visibility and make smarter decisions that lead to cost savings and higher customer satisfaction.

Predictive analytics helps you optimize inventory by forecasting demand more accurately than traditional methods. You can adjust your stock levels in real time, reducing both overstock and stockouts. Retailers using supply chain predictive analytics often see up to a 30% drop in inventory imbalances. This improvement leads to higher profits and happier customers. Traditional approaches, which rely on simple averages, often miss sudden market changes. Predictive analytics lets you respond faster and keep your inventory aligned with actual demand.

Tip: When you use predictive analytics, you can spot trends early and adjust your inventory before issues arise.

You can use predictive analytics to identify and manage risks in your supply chain. This technology helps you spot problems like unreliable suppliers, geopolitical threats, transportation delays, and operational inefficiencies. With supply chain predictive analytics, you can act before risks become major disruptions. You also improve supplier performance and keep your operations running smoothly. Predictive analytics gives you the power to foresee challenges and protect your business from unexpected events.

Supplier performance plays a critical role in your supply chain’s success. You need to know which suppliers deliver on time, maintain high quality, and pose minimal risk. Predictive analytics gives you the tools to measure and improve supplier performance with precision.

You start by collecting historical data from your suppliers. This data includes delivery times, product quality, and past incidents. Machine learning algorithms analyze these large datasets to find patterns. You can then rank suppliers based on risk levels and reliability. For example, if a supplier often delivers late or ships defective products, predictive analytics will highlight these issues quickly.

You use structured risk assessment models, such as Failure Mode and Effects Analysis (FMEA), to quantify supplier risks. These models break down potential problems and assign scores to each risk factor. You can develop a supplier risk score using predictive analytics. This score gives you a clear, quantitative measure of each supplier’s reliability.

Here are some ways predictive analytics helps you evaluate supplier performance:

Tip: When you use predictive analytics, you can spot unreliable suppliers before they cause problems. This proactive approach helps you maintain a smooth and efficient supply chain.

You gain the ability to make informed decisions about which suppliers to trust. You also reduce the risk of disruptions and improve overall supply chain resilience. Predictive analytics transforms supplier management from guesswork into a data-driven process.

You begin your journey with predictive analytics in supply chain by gathering data from many sources. You collect distributor reports, supply chain management software data, inventory records, and maintenance logs. You also include public data such as weather reports, consumer spending, traffic information, and industrial production records. Each source adds a layer of insight to your analysis.

You connect these data streams using cloud platforms. Cloud integration gives you real-time access to information, which is essential for effective decision-making. You can unify data from different departments and systems, making your supply chain predictive analytics more powerful. IoT sensors play a key role in modern supply chains. These sensors generate data about shipments, equipment status, and environmental conditions. You train your analytics teams to interpret this data and spot trends quickly.

Tip: When you integrate data from multiple sources, you create a foundation for accurate predictive analytics. This step helps you see the big picture and respond to changes in your supply chain.

Key steps for implementing predictive analytics in supply chain operations:

After collecting and integrating your data, you move to the analysis and modeling stage. You use predictive analytics to uncover patterns and forecast future outcomes. You apply forecasting methods such as time series analysis, regression analysis, and machine learning algorithms. Each technique offers unique strengths for supply chain predictive analytics.

You build models that simulate different scenarios. These models help you answer questions like, "What happens if demand spikes next month?" or "How will a supplier delay affect inventory levels?" You use predictive analytics to test these scenarios and prepare for possible outcomes.

Note: When you use advanced modeling techniques, you improve the accuracy of your supply chain predictive analytics. You gain confidence in your forecasts and make better decisions.

Machine learning and AI take predictive analytics to the next level. You use these technologies to analyze historical data and improve forecasting. AI models identify complex relationships between variables, which enhances lead time prediction accuracy. Automated feature selection reduces manual errors and increases reliability.

You use deep learning techniques for demand forecasting. These methods detect patterns that human analysis might overlook. Machine learning algorithms help you align inventory with customer needs, reducing stockouts and overstock situations. Anomaly detection capabilities allow you to respond immediately to disruptions in lead times.

Here is how machine learning and AI enhance predictive analytics in supply chain management:

| Aspect | Description |

|---|---|

| Historical Data | AI and ML use historical data for better forecasting. |

| Demand Forecasting | Advanced statistical and deep learning techniques improve demand prediction. |

| Inventory Optimization | AI helps optimize inventory levels with accurate predictions. |

| Risk Management | Predictive analytics identifies market dynamics and potential disruptions. |

| Operational Efficiency | Data-driven decisions streamline operations and reduce costs. |

You analyze historical sales patterns and market trends. Machine learning algorithms detect patterns that you might miss. Accurate predictions help you align inventory with customer needs. You use predictive analytics to make your supply chain more agile and resilient.

Tip: When you combine machine learning and AI with predictive analytics, you unlock new levels of accuracy and efficiency in your supply chain.

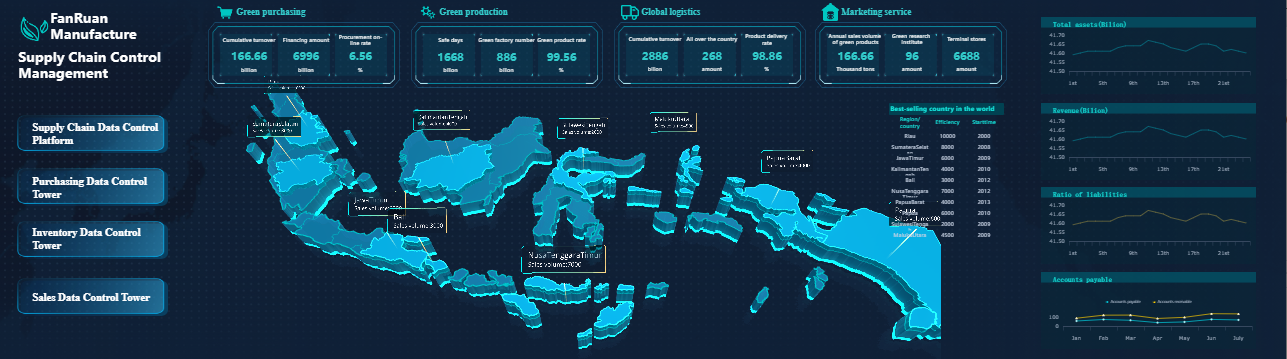

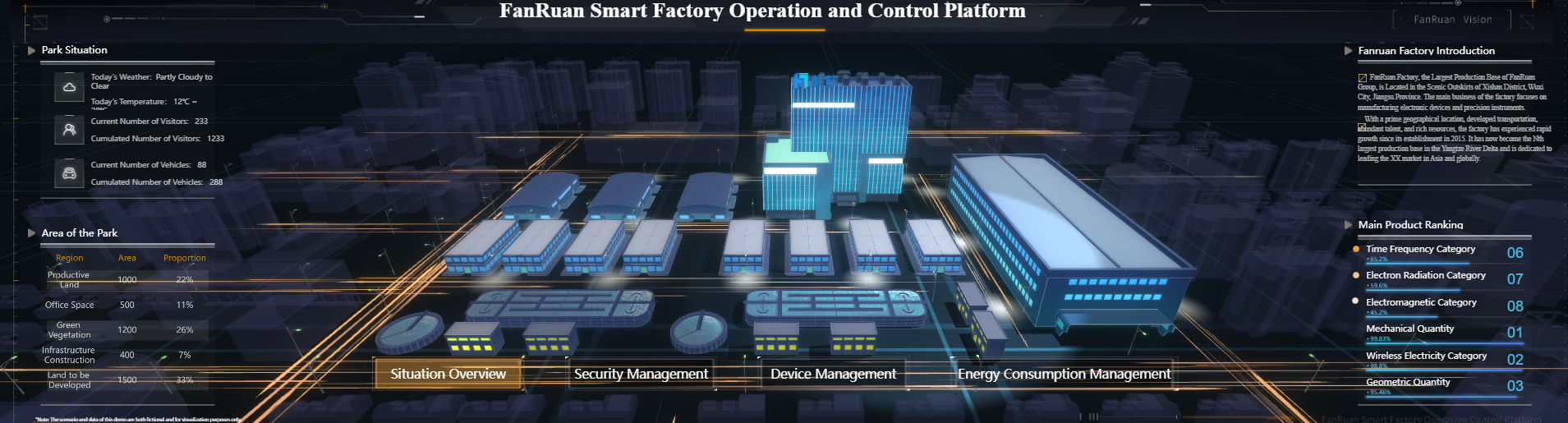

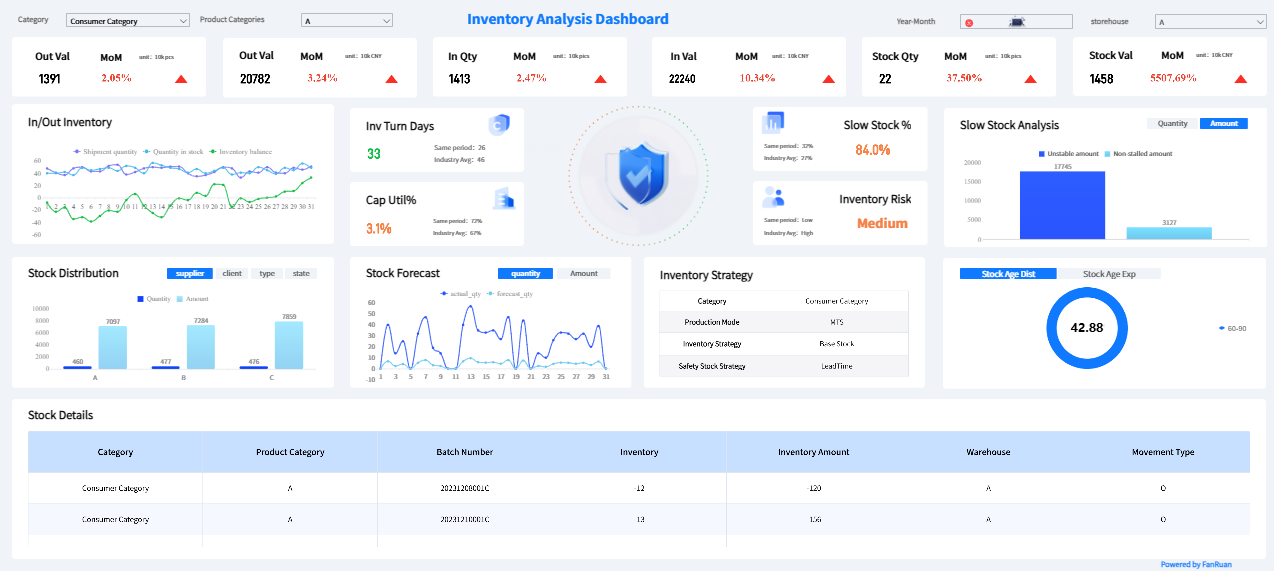

Predictive analytics in supply chain management requires a platform that can handle large volumes of data, integrate information from many sources, and deliver actionable insights quickly. You need a tool that supports every step of the predictive analytics process, from data collection to visualization. FineReport stands out as a powerful solution for these needs.

Why You Need a Robust Platform for Predictive Analytics in Supply Chain

You face many challenges when you try to implement predictive analytics in supply chain management. Data often comes from different systems, such as ERP, CRM, warehouse management, and even IoT sensors. You must bring all this data together, clean it, and prepare it for analysis. You also need to build models, visualize results, and share insights with your team. Without the right platform, these steps can become slow and error-prone.

Note: A strong predictive analytics platform helps you move from raw data to real business value. It lets you make decisions based on facts, not guesses.

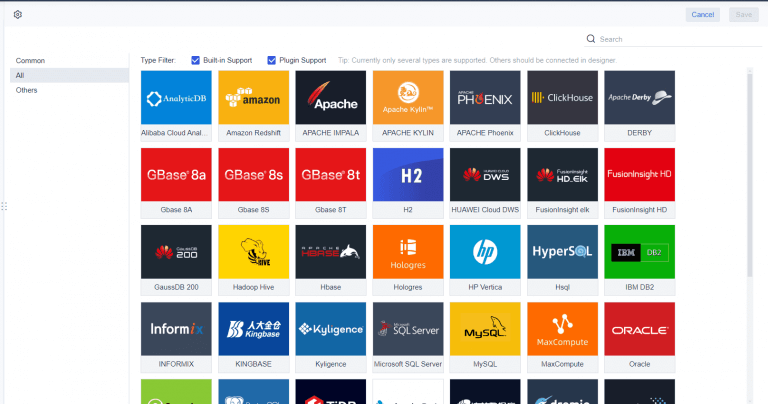

How FineReport Supports Predictive Analytics in Supply Chain

FineReport gives you a complete workflow for predictive analytics in supply chain management. You can connect to over 60 types of data sources, including databases, cloud warehouses, big data platforms, and APIs. This means you can unify your supply chain data, no matter where it lives.

Here is how FineReport helps you at each stage:

| Stage | What You Can Do with FineReport |

|---|---|

| Data Integration | Connect to multiple sources, schedule updates, and unify data |

| Data Processing | Clean, join, and transform data without coding |

| Visual Exploration | Build interactive dashboards with drag-and-drop simplicity |

| Publishing & Governance | Share insights securely and manage user access |

You can upload files, connect to APIs, or use custom connectors for legacy systems. FineReport's flexible integration ensures you never miss important supply chain data.

Self-Service Data Preparation and Modeling

FineReport lets you prepare and process data on your own. You can select fields, join tables, add calculated metrics, and filter records—all with a few clicks. You do not need to write code. This self-service approach saves time and reduces your reliance on IT teams.

You can also merge data from different departments, such as sales, inventory, and procurement. This gives you a complete view of your supply chain. Clean and consistent data is the foundation for accurate predictive analytics in supply chain management.

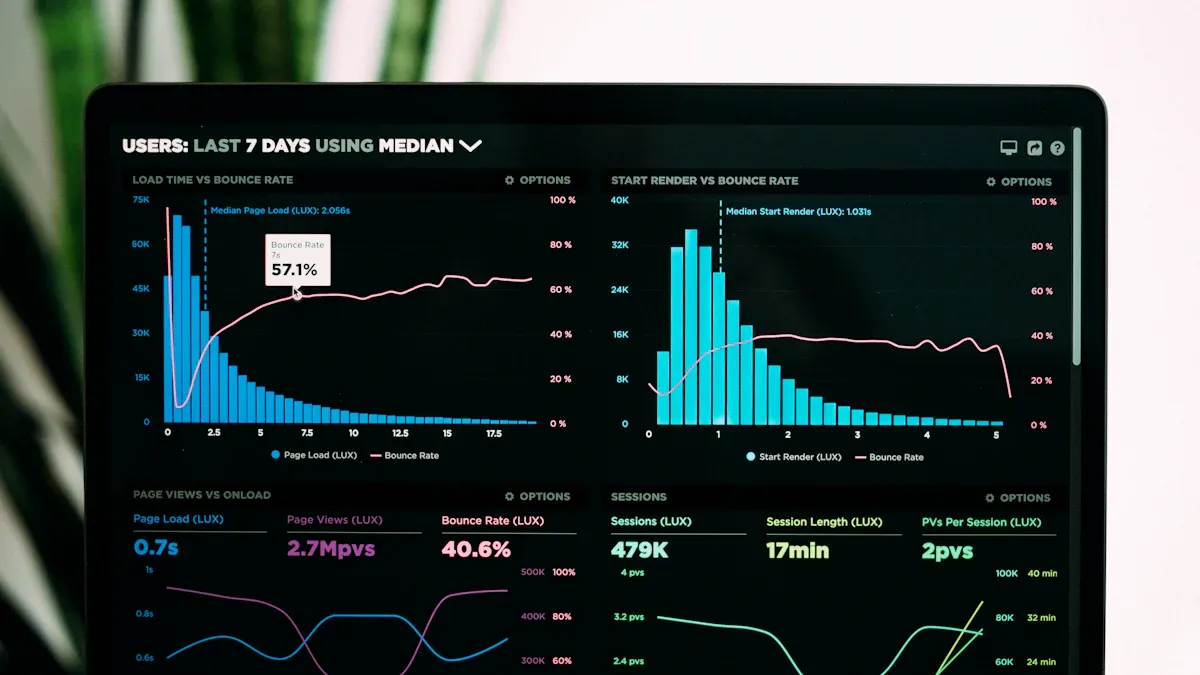

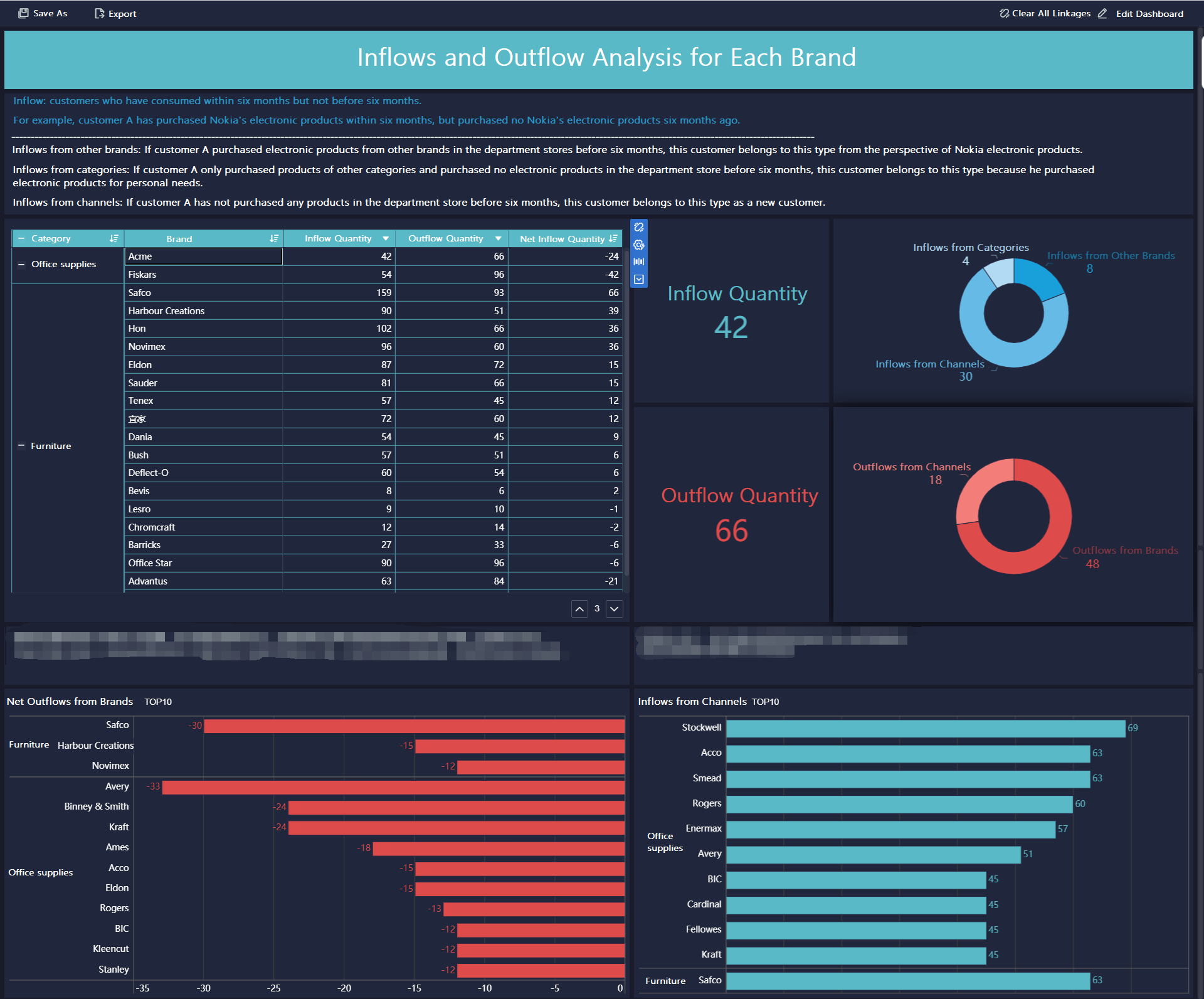

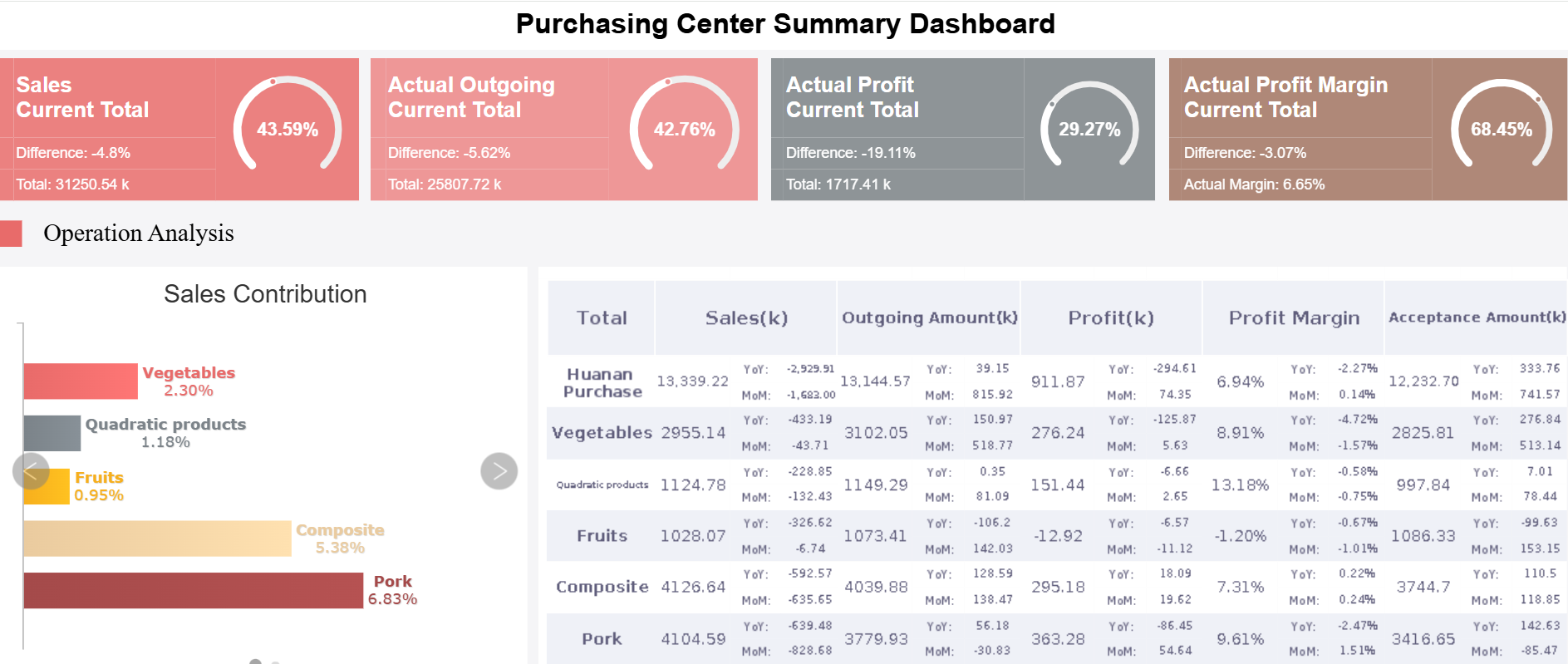

Advanced Analytics and Visualization

With FineReport, you can build dashboards that show key supply chain metrics in real time. You can use over 60 types of charts and tables to visualize trends, spot anomalies, and track performance. FineReport supports OLAP analysis, so you can drill down into details or switch between different views easily.

Tip: Use FineReport's real-time filtering to explore your supply chain data from different angles. This helps you find hidden patterns and make better predictions.

AI-Driven Insights and Predictive Modeling

FineReport goes beyond basic reporting. You can use its advanced analytics features to build predictive models. FineReport integrates machine learning algorithms that help you forecast demand, optimize inventory, and assess supplier risks. You can automate alerts for critical events, such as low stock or delayed shipments.

Collaboration and Data Governance

You can share dashboards and reports with your colleagues securely. FineReport supports role-based access control, so only authorized users see sensitive data. You can track user activity and ensure compliance with company policies.

Key Benefits of Using FineReport for Predictive Analytics in Supply Chain

Note: FineReport helps you turn predictive analytics in supply chain management into a practical, everyday tool. You gain the power to anticipate problems, optimize operations, and drive business growth.

By choosing FineReport, you equip your organization with a modern, self-service platform that makes predictive analytics in supply chain management simple, fast, and effective.

You can transform your supply chain operations by using predictive analytics. This technology helps you streamline processes, reduce waste, and save money. When you analyze data from sales, inventory, and logistics, you spot inefficiencies quickly. You can adjust your inventory levels to match real demand, which prevents both overstock and stockouts. Many organizations report measurable improvements after adopting predictive analytics in supply chain management.

Here is a summary of the most common benefits:

| Benefit | Description |

|---|---|

| Accurate demand forecasting | You determine customer demand more precisely. |

| Efficient inventory management | You optimize inventory levels and avoid shortages or excess stock. |

| Reduction of stock-outs | You minimize situations where products are unavailable for customers. |

| Elimination of overstock | You prevent excess inventory that ties up valuable capital. |

| Improved logistics management | You enhance the efficiency of your logistics operations. |

| Identification of disruptions | You spot potential disruptions and bottlenecks before they escalate. |

By using predictive analytics, you make smarter decisions that lead to lower costs and higher productivity.

Predictive analytics gives you the power to understand your customers better. You can analyze buying patterns and predict what products customers will want next. This insight allows you to keep the right products in stock and deliver them on time. When you reduce stockouts and ensure timely deliveries, your customers stay happy and loyal.

You also improve product quality by identifying issues early. Fewer defective goods reach your customers, which boosts their trust in your brand. When you tailor your offerings based on customer behavior, you create a more personalized experience. This approach leads to higher satisfaction and repeat business.

Predictive analytics helps you move from reacting to problems to preventing them. You can forecast demand more accurately, which reduces the risk of running out of stock or holding too much inventory. You also optimize your inventory turnover, saving money and space.

Here is how predictive analytics supports proactive problem solving:

Tip: When you use predictive analytics, you stay ahead of disruptions and keep your supply chain running efficiently.

You can strengthen collaboration across your supply chain by using predictive analytics. When you share data and insights with your partners, you build trust and improve teamwork. Predictive analytics gives you tools to break down barriers between departments and organizations. You see the same information as your suppliers, logistics providers, and customers. This shared visibility helps everyone work toward common goals.

Real-time data plays a key role in supply chain collaboration. You track shipments, monitor inventory, and spot potential bottlenecks before they become problems. When you use predictive analytics, you get alerts about delays or shortages. You can adapt your strategies quickly and keep your supply chain running smoothly.

Here are some ways predictive analytics improves collaboration:

Tip: When you use shared dashboards, you make it easier for teams to coordinate and solve problems together.

You also improve relationships with suppliers and stakeholders. When everyone has access to accurate forecasts and performance metrics, you build trust and accountability. You can set clear expectations and measure results. This transparency leads to better negotiations and stronger partnerships.

Predictive analytics helps you create a more agile and resilient supply chain. You work together with your partners to solve problems, optimize processes, and deliver value to your customers. By embracing data-driven collaboration, you set your organization up for long-term success.

You can see the impact of supply chain predictive analytics in retail every day. Major retailers use advanced analytics to manage inventory, reduce waste, and meet customer demand. You track sales trends, analyze customer behavior, and optimize stock levels across thousands of stores. This approach helps you avoid overstock and stockouts.

Here is how leading retailers apply supply chain predictive analytics:

| Retailer | Challenge | Solution | Result |

|---|---|---|---|

| Walmart | Managing inventory across thousands of stores while reducing overstock and waste. | Implemented AI-based predictive analytics to track sales trends, anticipate stock needs, and optimize replenishment cycles. | Improved demand forecasting accuracy by 90%, reducing stockouts and excess inventory. |

| Amazon | Handling inventory for millions of products across global warehouses. | Analyzed real-time sales, customer behavior, and supplier performance to automate inventory restocking. | Increased supply chain efficiency and improved delivery timelines with predictive fulfillment centers. |

| Zara | Aligning inventory with rapidly changing fashion trends. | Uses AI for trend analysis and real-time inventory tracking to send the right products to stores. | 85% of products manufactured based on real-time demand, reducing unsold inventory and markdowns. |

| Target | Meeting customer demand across various regions while minimizing overstock. | Analyzed buying behavior, regional sales trends, and external factors like weather patterns. | Improved sales forecasting accuracy, leading to better inventory distribution and optimized stock levels. |

You benefit from more accurate forecasts and better inventory control. Supply chain predictive analytics helps you deliver the right products at the right time.

You rely on supply chain predictive analytics to improve logistics and transportation planning. You use historical data and machine learning to forecast demand and optimize fleet management. This technology helps you plan routes, reduce delays, and cut costs.

Many companies invest in digital solutions to gain end-to-end visibility. DHL created MySupplyChain, a platform that uses predictive analytics to optimize operations. Maersk uses predictive maintenance tools to allocate resources efficiently. You can also reduce transport emissions by planning smarter routes. In the US, 35% of heavy truck miles are driven empty. Predictive analytics helps you fill those gaps and lower your carbon footprint.

Tip: When you use supply chain predictive analytics, you improve delivery timelines and make your logistics more sustainable.

You use supply chain predictive analytics to assess supplier risks and protect your business. You analyze supplier performance, delivery times, and quality records. Predictive models help you spot potential problems before they disrupt your supply chain.

The DRIVE solution from Plexus shows how predictive analytics can identify and mitigate risks. You gain reliable insights into supplier reliability and can act quickly to prevent issues. This approach ensures you maintain a steady flow of goods and avoid costly disruptions.

Note: Supply chain predictive analytics gives you the tools to build a resilient supply chain and make informed decisions about your suppliers.

You can use predictive analytics to transform your approach to production scheduling. This technology lets you move from reactive to proactive planning. By analyzing both historical and real-time data, you can anticipate equipment failures and adjust your production schedules before problems occur. This shift helps you reduce downtime and keep your operations running smoothly.

Manufacturers rely on a wide range of data sources to make accurate predictions. You might use IoT sensors to monitor machines in real time. Manufacturing Execution Systems (MES) track production progress, while ERP systems manage business operations. You can also include data from partners, customer demand patterns, and industry databases. This comprehensive data ecosystem gives you a clear view of your entire production process.

When you combine these data streams, you gain the power to predict and prevent disruptions.

Here are some ways predictive analytics improves production scheduling:

Predictive maintenance stands out as a key benefit. In recent studies, predictive models achieved a precision of 0.90 and a recall of 0.60 when forecasting downtime. This means that 90% of predicted downtimes were accurate, and the models balanced detection well, with F1 scores between 0.70 and 0.85.

You can use these insights to schedule repairs during low-demand periods, minimizing disruption. As a result, you boost operational efficiency and keep your production lines moving. Predictive analytics gives you the tools to make smarter, faster decisions in production scheduling.

You need high-quality data to make predictive analytics work in supply chain management. When your data is accurate and complete, predictive models give you reliable results. Poor data quality can create noise, which distorts predictions and leads to mistakes. You must monitor your data regularly to catch errors before they affect your supply chain. Good data helps you reduce waste and avoid excess inventory. Accurate inventory records lower holding costs and prevent emergency orders. Data quality is a strategic asset that lets you deliver value, manage risks, and control costs. If you want predictive analytics to improve your supply chain, you must focus on data integrity and readiness.

You face technical challenges when you add predictive analytics to your current supply chain systems. Legacy platforms often use different formats and standards, making integration complex. You may need to connect predictive analytics tools to multiple data sources, which requires careful planning and investment. Compatibility issues can slow down your progress and increase costs. You must also deal with resistance from employees who prefer familiar systems.

| Challenge | Description |

|---|---|

| Poor Data Quality and Accuracy | Inconsistent, incomplete, or outdated data can lead to unreliable predictions, negatively affecting decision-making and supply chain resilience. |

| Higher Integration Complexity | Integrating predictive analytics with legacy systems can be complex due to compatibility issues and multiple data sources, requiring significant investment. |

| Resistance to Adoption | Organizational culture and employee reluctance to embrace new technology can hinder the successful implementation of predictive analytics. |

You can overcome these challenges by choosing flexible predictive analytics platforms that support many data sources and offer easy integration. When you plan carefully, you make predictive analytics a valuable part of your supply chain.

You must address change management and the skills gap when you introduce predictive analytics. Many employees resist new processes, which creates cultural barriers. You need effective strategies to help your team adapt. Data literacy is another major challenge. If your staff cannot interpret predictive outputs, you miss out on valuable insights. Nearly 63% of businesses see the skills gap as a major obstacle to adopting predictive analytics. Research shows that 67% of supply chain professionals lack basic data analytics skills. Companies respond by investing in upskilling programs and hiring AI-savvy professionals. You can build a stronger team by focusing on training and education.

Tip: When you support your team with training and clear communication, you make predictive analytics easier to adopt and more effective in your supply chain.

You face serious privacy and security challenges when you use predictive analytics in supply chain management. The supply chain moves large amounts of sensitive information every day. You must protect trade secrets, supplier contracts, and customer records from cyber threats. Every connection in your supply chain can introduce new risks. Hackers often target valuable data, looking for weaknesses in your systems.

As artificial intelligence becomes more embedded in supply chain analytics, privacy will take on even greater importance. Algorithms that rely on sensitive supplier data must be trained and deployed responsibly.

You need to understand the main risks that come with predictive analytics:

You must take steps to secure your data. Strong encryption, regular audits, and strict access controls help you keep information safe. You should train your team to spot phishing attempts and avoid sharing confidential data with unauthorized users. You also need to monitor your systems for unusual activity. Quick action can prevent a small breach from becoming a major disaster.

If you fail to protect your data, you may face serious consequences:

Cybersecurity in supply chains is an ongoing challenge, with evolving threats that require constant vigilance. A single breach can lead to severe financial losses and damage to a brand's reputation. You must stay alert and update your security measures regularly. By making privacy and security a top priority, you protect your business and build trust with your partners and customers.

You will see rapid changes in predictive analytics as AI and machine learning continue to evolve. These technologies help you forecast demand, manage inventory, and reduce risks in your supply chain. AI-powered predictive analytics use big data to streamline operations and improve logistics. You can expect future advancements to combine AI with blockchain and IoT, which will give you better transparency and responsiveness.

Real-time analytics and IoT integration are transforming predictive analytics in supply chain management. You gain better visibility and more accurate demand forecasting when you use these tools. Companies that use AI and predictive analytics report a 20% reduction in supply chain costs and a 10% increase in revenue. Top-performing supply chains rely on predictive analytics to achieve above-average growth.

Tip: Real-time predictive analytics let you respond to disruptions before they affect your business.

You will notice more organizations adopting tools like FineReport to support predictive analytics in supply chain management. Predictive analytics is now a strategic priority for executives who want to maintain business continuity and drive growth. Companies combine predictive analytics with traditional business intelligence platforms for a more complete approach to data analysis.

Note: The future of supply chain predictive analytics depends on your ability to integrate predictive tools with your existing systems and processes.

You see sustainability becoming a top priority in supply chain management. Predictive analytics gives you powerful tools to make your supply chain greener and more responsible. When you use data-driven insights, you can reduce waste, lower emissions, and support ethical business practices.

You start by optimizing inventory levels. Predictive analytics helps you match stock with actual demand. This approach prevents overproduction and reduces waste. You use fewer resources and avoid unnecessary disposal of unsold goods. You also improve resource utilization, which means you get more value from every item you produce or ship.

Efficient transportation planning is another area where predictive analytics makes a difference. You analyze delivery routes and schedules. By choosing the best routes, you minimize travel distance and fuel consumption. This strategy lowers transportation costs and cuts carbon emissions. You help your company meet environmental goals and comply with regulations.

You can also use predictive analytics to support ethical sourcing. You assess supplier practices and monitor compliance with social responsibility standards. When you identify suppliers who follow ethical guidelines, you strengthen your brand reputation. You build trust with customers and partners who care about sustainability.

Here are some ways predictive analytics drives sustainability in supply chain management:

Tip: When you focus on sustainability, you create long-term value for your business and the environment. Predictive analytics helps you make smarter choices that benefit both your company and the planet.

You play a key role in shaping a sustainable future. By using predictive analytics, you make your supply chain more efficient, ethical, and environmentally friendly.

You can transform your supply chain management by using predictive analytics in supply chain. Predictive analytics helps you forecast demand, optimize inventory, and reduce risks. You gain real-world benefits such as improved efficiency and better collaboration. Many industries use predictive analytics to solve problems and drive growth. If you want to unlock new insights, consider exploring platforms like FineReport for your supply chain needs.

What is Supply Chain Risk Management Process and How It Work

Supply Chain Risk Explained and Why it Matters Now

What is Supply Chain Visibility and Why Does It Matter

Supply Chain Analytics Explained and Its Importance

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

9 Best Supply Chain Tools for Smarter Management in 2026

Find the best supply chain tools for 2025 to boost efficiency, gain real-time insights, and achieve smarter management for your business.

Lewis

Dec 18, 2025

Top 10 Supply Chain Tracking Software for 2026

Compare the top supply chain tracking software for 2026 to boost visibility, automate workflows, and leverage AI analytics for smarter decisions.

Lewis

Dec 18, 2025

Top 10 Supply Chain Management Software for Small Businesses

See the top 10 supply chain management software comparison for small businesses in 2026. Compare features, pricing, and scalability to find your best fit.

Lewis

Dec 18, 2025