Supply chain visibility gives you the power to track, monitor, and understand every activity in your supply chain as it happens. When you gain an end-to-end view of your operations, you can spot issues early, reduce risks, and make better decisions. With real-time supply chain visibility, companies often see a 50% drop in process costs and a 20% jump in revenue. You also get improved inventory accuracy, higher customer satisfaction, and stronger risk management. FineReport helps you achieve this level of transparency by offering advanced reporting, interactive dashboards, and seamless real-time data integration.

You can transform your business performance by focusing on supply chain visibility. When you see every step in your supply chain, you make smarter decisions and respond faster to changes. Many companies have reported measurable improvements after adopting supply chain analytics and real-time monitoring tools. For example, Unilever and Walmart documented significant cost savings and better supplier relationships through enhanced transparency.

Here is a table that shows the most significant ways supply chain visibility improves business performance:

| Benefit of Supply Chain Visibility | Description |

|---|---|

| Enhanced Collaboration | Seamless data integration fosters collaboration and transparency among stakeholders. |

| Risk Mitigation | Early identification of potential risks through real-time data monitoring. |

| Operational Efficiency | Optimization of supply chain processes reduces waste and lowers costs. |

| Inventory Management | Better visibility into inventory levels aids in stock management. |

| Customer Satisfaction | Timely delivery through accurate demand forecasting boosts customer loyalty. |

| Sustainability | Supports compliance with environmental and regulatory standards, enhancing brand reputation. |

You can also see real-world results such as saving $300,000 to $500,000 per month on fines and penalties, improving capacity by 4% across the industry, and reducing detention costs by $10 million annually. Businesses with strong supply chain visibility often navigate disruptions without losing revenue and achieve higher profitability. These outcomes highlight the importance of supply chain visibility for any organization that wants to stay competitive.

Supply chain management faces many risks, from shipping delays to sudden changes in demand. When you have real-time access to data and share information across your network, you can spot problems early and act quickly. This approach builds resilience and helps you avoid costly disruptions.

Research shows that companies using digital technologies like AI and blockchain can anticipate disruptions and create effective backup plans. During the COVID-19 pandemic, many organizations learned that limited visibility made it hard to respond to supply chain shocks. For example, a computer assembler discovered that most of its key suppliers were concentrated in one region, which led to major delays when that area faced problems. This situation proves that a lack of transparency exposes hidden risks and slows down recovery.

Here is a table of common risks that supply chain visibility helps you manage:

| Risk Type | Description |

|---|---|

| Logistics Risks | Issues such as shipping problems, bottlenecks, and port closures that disrupt supply chains. |

| Demand Volatility | Rapid changes in consumer demand requiring agile responses from businesses. |

| Lack of Transparency | Inefficiencies caused by poor communication and visibility in the supply chain. |

| Business Information Risks | Risks associated with inaccurate or insufficient data affecting decision-making. |

By using supply chain analytics, you can monitor these risks and respond before they become bigger problems. You also improve your ability to recover from unexpected events, which is essential for long-term success in supply chain management.

Customer satisfaction depends on your ability to deliver products on time and keep your promises. Supply chain visibility gives you the tools to track orders, monitor shipments, and communicate with customers in real time. When you know exactly where each order stands, you can prevent delays and fix issues before they affect your customers.

High on-time delivery rates are crucial for meeting customer demand and building trust. Companies that monitor these metrics can spot problems in their supply chain cycle and make improvements quickly. Order visibility is especially important in a customer-centric supply chain. Customers expect to track their orders in real time, and meeting this expectation increases satisfaction.

In the retail sector, a large e-commerce company improved its Net Promoter Score by fixing delivery issues and damaged products. After making these changes, the company saw more repeat purchases and a better reputation. In the pharmaceutical industry, better inventory management and supplier relationships led to fewer stockouts and higher trust from patients and healthcare providers.

Tip: When you invest in supply chain visibility, you not only improve your operations but also create loyal customers who trust your brand.

Understanding the different types of supply chain visibility helps you manage your operations more effectively. Each type focuses on a specific area, giving you the tools to track, analyze, and improve your supply chain performance.

| Type | Definition |

|---|---|

| Order Details | Information about a product's order, including tracking and shipment updates. |

| Component Location | The physical location of a product, aiding in delivery process and estimated delivery times. |

| Inventory | Availability of products, providing real-time data on stock levels in warehouses or trucks. |

| Costs | Rates and expenses related to transportation, crucial for understanding total shipment costs. |

| Auditing Records | Documents detailing transactions, costs, and freight movement, essential for financial oversight. |

Order visibility lets you track every stage of an order, from placement to delivery. You can see where each order stands, which helps you respond quickly to changes or delays. When you have strong order visibility, you reduce errors and improve communication with your customers.

However, you may face challenges such as:

By addressing these challenges, you create a smoother order management process and boost customer satisfaction.

Inventory visibility gives you real-time insight into your stock levels across warehouses, trucks, or stores. You can avoid overstocking or running out of products. This type of visibility is essential for efficient supply chain management.

| Evidence Type | Description |

|---|---|

| Inventory Turnover Impact | Companies with optimized supply chains enjoy up to 15% lower costs compared to competitors. |

| Stockout Cost | Stockouts may lead to lost sales worth up to 4.1% of annual revenue. |

| Predictive Analytics | Businesses using predictive analytics can reduce stockouts by up to 65% and lower inventory levels by 20-30%. |

When you improve inventory visibility, you lower costs and reduce the risk of stockouts. You also gain the ability to use predictive analytics, which helps you plan better and meet customer demand.

Tip: Accurate inventory visibility supports faster decision-making and helps you avoid costly mistakes.

Shipment visibility allows you to monitor your cargo in real time. You can track shipments, receive alerts for delays, and make quick decisions to keep your supply chain running smoothly. Technologies such as GPS, RFID tags, IoT sensors, and blockchain play a key role in providing this visibility. Tools like Ziegler Order Entry (ZOE) and Easy Track also help you gain detailed insights into the shipping process.

With shipment visibility, you can optimize routes, reduce delivery times, and improve overall efficiency. Real-time monitoring ensures you stay informed and ready to act if problems arise.

Production visibility gives you a clear view of every step in your manufacturing process. You can track raw materials, monitor work-in-progress, and see finished goods as they move through your factory. This level of insight helps you understand exactly what happens on your production floor at any moment.

When you achieve strong production visibility, you gain several important advantages:

Tip: Real-time production data helps you make better decisions and keep your manufacturing on schedule.

Here is how production visibility helps you reduce manufacturing lead times:

| Benefit | How It Helps Production |

|---|---|

| Faster Problem Solving | You react to issues as soon as they appear. |

| Improved Scheduling | You plan production runs with accurate data. |

| Higher Product Quality | You catch defects early and maintain standards. |

Production visibility also supports collaboration between departments. When everyone sees the same data, you reduce confusion and improve teamwork. You can share updates with suppliers and partners, which keeps your supply chain running smoothly.

If you want to stay competitive in manufacturing, you need to know what happens in your production process at all times. Production visibility gives you the tools to optimize performance, reduce costs, and deliver products on time.

Supply chain visibility gives you the information you need to make smarter choices every day. When you can track goods in near real time, you spot material shortages before they become a problem. You also see where inventory sits, which helps you plan better and avoid surprises. With clear data, you make faster decisions and allocate resources where they matter most.

Here is a table that shows how supply chain visibility supports better decision making:

| Benefit | Description |

|---|---|

| Spot material and inventory shortages | Identify weaknesses in inventory and plan accordingly. |

| Track goods in near real time | Get a detailed view of the product lifecycle for better decisions. |

| Make faster decisions | Understand the supply chain clearly for informed resource allocation. |

| Reduce costs | Find cost-saving opportunities and inefficiencies. |

| Manage risk | See potential risk indicators and respond quickly. |

| Efficiently meet regulatory compliance | Share information to ensure compliance with regulations. |

You also improve strategic planning, monitor tactical execution, and benchmark your performance against industry standards.

You can save money across your entire operation when you have strong supply chain visibility. Real-time tracking helps you resolve bottlenecks and streamline warehouse operations, which leads to a 20% reduction in lead times. Companies using advanced visibility tools have reduced out-of-stock scenarios by 25%. You also avoid costly expedited shipments by planning orders efficiently.

Some of the top ways supply chain visibility drives cost savings include:

When you track shipments at every step, you plan better and avoid unnecessary expenses. Enhanced visibility helps you identify inefficiencies and eliminate redundancies, leading to significant cost savings.

Supply chain visibility strengthens collaboration between you and your partners. When you share data with suppliers, they can better anticipate your needs and adjust their schedules. Manufacturers and distributors benefit from timely feedback, which reduces miscommunication and aligns production with demand.

Connecting all stakeholders on a single platform ensures everyone stays on the same page. This collaborative approach helps you adapt quickly to market changes and maintain reliable service. You also unlock mutual value with suppliers, increase customer satisfaction, and boost your team’s productivity.

Tip: When you foster collaboration through visibility, you build stronger relationships and create a more agile supply chain.

Supply chain disruptions can happen at any time. When you have strong visibility, you can respond to these challenges much faster. You see issues as they develop, not after they have already caused damage. This proactive approach helps you keep your business running smoothly, even when unexpected events occur.

With real-time data, you gain the ability to spot problems before they escalate. For example, if a shipment faces a delay, you receive an alert immediately. You can then reroute shipments or switch to another supplier without waiting for the issue to grow. This flexibility keeps your operations on track and reduces the risk of lost revenue.

Tip: Real-time alerts and dashboards help you act quickly. You do not need to wait for manual reports or emails to know something has gone wrong.

Predictive analytics also play a key role in faster problem resolution. By analyzing trends, you can anticipate risks and adjust your operations before problems arise. AI-powered platforms help you identify alternative suppliers and optimize inventory in real time. This technology gives you more options and helps you avoid costly delays.

Here are some ways supply chain visibility supports faster problem resolution:

When you use these tools, you build a more resilient supply chain. You solve problems faster, reduce downtime, and keep your customers satisfied. Supply chain visibility turns challenges into opportunities for improvement.

Achieving full supply chain visibility is not always easy. You may face several obstacles that make it hard to get a clear view of your operations. Understanding these challenges helps you find better solutions and improve your supply chain management.

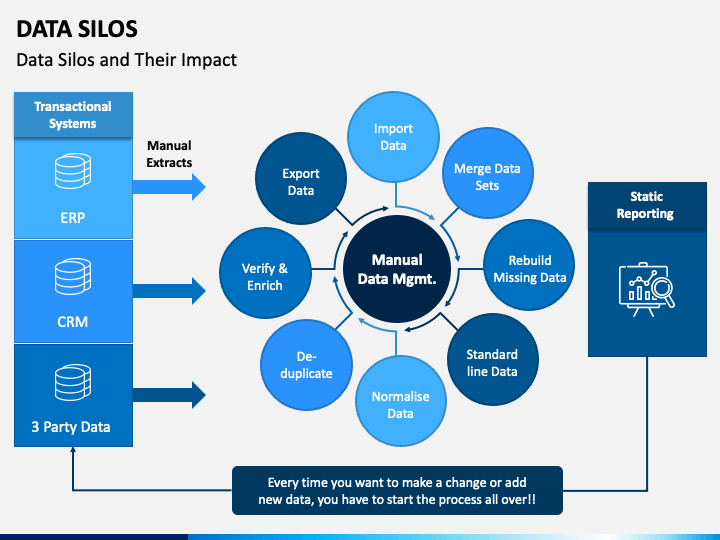

Data silos occur when departments or teams keep their information separate. You might see insights scattered across different systems, making it hard to get a complete picture. This fragmentation leads to reduced data accuracy and consistency. When you cannot access unified supply chain data, your operations become less efficient and you risk making decisions based on incomplete information.

To overcome data silos, you can integrate data from various sources, set up strong data governance policies, and encourage collaboration between departments. Using unified reporting tools also helps you align performance metrics and improve transparency.

Without real-time information, you cannot respond quickly to changes in your supply chain. Many organizations struggle because they rely on outdated data or manual updates. This delay makes it hard to track shipments, monitor inventory, or spot problems before they grow.

A lack of real-time supply chain data means you might miss out on important trends or fail to meet customer demand. High levels of end-to-end visibility are crucial for tracking supplies and making informed decisions. When you have access to live data, you can act faster and keep your supply chain running smoothly.

Tip: Real-time dashboards and alerts help you stay ahead of disruptions and improve your decision-making.

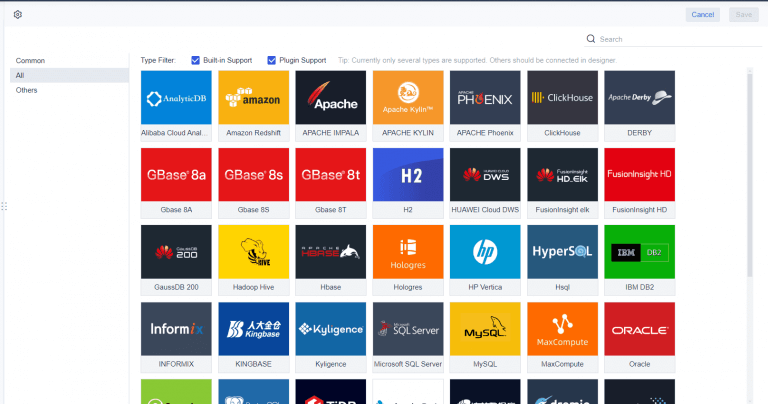

Integrating different systems is another major challenge. You may use new software that does not work well with your older systems. This can lead to data inconsistencies, information loss, or delays in processing transactions. Migrating data from old platforms to new ones often takes time and can introduce errors if data quality is poor.

Here is a table showing common integration issues:

| Integration Issue | Description |

|---|---|

| Compatibility Issues | New systems may not work with legacy software or hardware, causing data inconsistencies. |

| Data Migration Problems | Moving data to new platforms can be error-prone and time-consuming. |

| Lack of Standardization | Different formats and processes make it hard to combine data from multiple sources. |

| Lack of Data Accuracy | Poor data quality leads to errors and inefficiencies in supply chain operations. |

| Data Silos | Separate repositories create incomplete or inconsistent information. |

| Lack of Real-Time Data | Without live data, you cannot make timely decisions about orders or inventory. |

You can address these issues by standardizing data formats, improving data quality, and choosing integration tools that support both new and legacy systems. This approach helps you build a more connected and efficient supply chain.

You may find that resistance to change is one of the biggest barriers when you try to improve supply chain visibility. Many employees feel uncertain about new technologies. They might worry about losing their jobs or struggle to understand how new systems will affect their daily work. These concerns can slow down or even stop the adoption of better supply chain solutions.

People often prefer familiar routines. When you introduce new tools or processes, some team members may hesitate. They might fear that automation will replace their roles or that learning new software will be too difficult. This hesitation can create friction within your organization.

Tip: Open communication helps reduce fear. When you explain the reasons for change and show the benefits, you help your team feel more comfortable.

You can address resistance by focusing on three key actions:

Here is a table that shows common reasons for resistance and ways to overcome them:

| Reason for Resistance | How to Overcome |

|---|---|

| Fear of job loss | Highlight new opportunities |

| Lack of familiarity | Provide step-by-step training |

| Workflow disruption | Show how processes will improve |

You can build a culture that welcomes change. When you support your team and address their concerns, you make it easier to adopt new supply chain visibility solutions. This approach leads to better collaboration and long-term success.

You can transform your supply chain operations by investing in advanced technology solutions. FineReport stands out as a powerful tool that addresses common visibility challenges. It brings together data from different systems, such as ERP, MES, and SRM, onto a single platform. This integration gives you real-time insights and helps you make informed decisions quickly.

Here is a table showing how FineReport features solve visibility challenges:

| Feature | Description |

|---|---|

| Seamless Data Integration | Integrates data from various systems for real-time insights on a unified platform. |

| Low-Code Functionality | Simplifies data integration, effectively eliminating silos. |

| Comprehensive Data Visualization | Consolidates information into a single dashboard for easy interaction and analysis. |

When you use FineReport, you gain measurable improvements in your supply chain. Companies have seen higher perfect order performance, shorter customer order cycle times, and better inventory management. You also improve your fill rate, which means more complete orders and fewer additional shipments.

| KPI | Description |

|---|---|

| Perfect order performance | Percentage of orders delivered complete and on time with no errors. |

| Customer order cycle time | Time taken for customers to receive their products. |

| Days inventory on hand | Indicates if a business has excess or insufficient inventory. |

| Fill rate | Percentage of complete orders that do not require additional shipments. |

You also benefit from enhanced operational efficiency and productivity. FineReport reduces communication delays between carriers and shippers and improves the management of loading and unloading processes. Customers want real-time access to their order information. When you provide direct access, you build trust and satisfaction. Meeting promised delivery dates further enhances the customer experience.

Modern technology offers even more advantages. Real-time data analytics can increase cost savings by 15-20% and improve service levels by 20-25%. AI-powered solutions reduce forecasting errors by 40% and cut operational costs by 10-15%. IoT technology improves tracking accuracy by up to 90%, especially in industries like pharmaceuticals. Blockchain technology enhances transparency and reduces traceability time from days to seconds. Most businesses using cloud-based solutions report improved agility and faster decision-making.

Tip: Investing in the right technology gives you a competitive edge and helps you respond quickly to market changes.

You can achieve better supply chain visibility by standardizing your data and processes. When you use consistent data formats and definitions across your business units and trading partners, you create a strong foundation for comparison and analysis. This approach ensures that everyone in your supply chain speaks the same language.

Standardization brings several benefits:

Data standardization can enable automated inventory management for products with expiration dates that require removal and replacement. Data synchronization between trade partners can enable faster, more efficient response to product recalls.

When you standardize your processes, you also support automation. Automated systems can handle routine tasks, freeing your team to focus on more important work. This leads to fewer errors and faster response times. You also build trust with your partners because everyone follows the same rules and expectations.

You can further improve supply chain visibility by fostering collaboration with your partners. Strong relationships and open communication channels help you share information quickly and accurately. Start by establishing clear communication channels with your suppliers and other stakeholders. Identify a clear point of contact at each partner organization. Set clear expectations about transparency and information-sharing.

Here are some best practices for effective collaboration:

When you align your goals and incentives with your partners, you create a shared vision for success. Technology plays a key role in this process. FineReport enables you to share dashboards and reports with your partners, giving everyone access to the same real-time data. This transparency helps you make better decisions together and respond quickly to changes in demand or supply.

Note: Collaboration is not just about sharing data. It is about building trust, setting clear expectations, and working towards common goals.

By investing in technology, standardizing your data, and fostering collaboration, you create a supply chain that is transparent, efficient, and resilient. FineReport gives you the tools to achieve these goals and stay ahead in a competitive market.

You play a key role in making supply chain visibility a success. Training your teams and building awareness are essential steps. When your employees understand the value of supply chain visibility, they work more efficiently and make better decisions. You give your business a strong foundation for growth and resilience.

Start by offering regular training sessions. Teach your team how to use digital tools and interpret data. When everyone knows how to read dashboards and reports, you reduce mistakes and improve consistency. Employees who understand the technology can spot issues early and respond quickly.

Tip: Ongoing education keeps your team up to date with the latest supply chain trends and tools.

You should also focus on building awareness across your organization. When people know why supply chain visibility matters, they become more engaged. They see how their actions affect the whole process. This awareness encourages collaboration with suppliers and partners. It also helps everyone work toward common goals.

Here are some ways training and awareness make a difference:

You can use different methods to train your teams. Workshops, online courses, and hands-on practice all help employees build their skills. Encourage your staff to ask questions and share what they learn. When you support learning, you build a culture of continuous improvement.

A resilient team can handle challenges and keep your supply chain running smoothly. Training in analytics and scenario planning prepares your employees for unexpected events. They learn to collaborate and address issues before they become serious problems.

Note: Investing in your people is just as important as investing in technology. When you train your teams and build awareness, you set your business up for long-term success in supply chain management.

You gain a clear advantage when you prioritize supply chain visibility. You improve productivity, customer satisfaction, and cost control. The table below shows how visibility drives long-term success:

| Benefit | Description |

|---|---|

| Improved Productivity | Spot shortages and plan resources better. |

| Enhanced Customer Satisfaction | Give accurate delivery updates and build trust. |

| Cost Reduction | Identify inefficiencies and optimize costs. |

| Risk Management | Respond quickly to potential risks. |

| Compliance | Meet regulations and reduce financial risks. |

| Stronger Partner Collaboration | Share data in real time and strengthen teamwork. |

| Competitive Edge | Forecast issues and optimize operations. |

You can achieve these outcomes with solutions like FineReport. You build a resilient and efficient supply chain for your business.

What is Supply Chain Risk Management Process and How It Work

Supply Chain Risk Explained and Why it Matters Now

Supply Chain Analytics Explained and Its Importance

What is Predictive Analytics in Supply Chain Management

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

9 Best Supply Chain Tools for Smarter Management in 2026

Find the best supply chain tools for 2025 to boost efficiency, gain real-time insights, and achieve smarter management for your business.

Lewis

Dec 18, 2025

Top 10 Supply Chain Tracking Software for 2026

Compare the top supply chain tracking software for 2026 to boost visibility, automate workflows, and leverage AI analytics for smarter decisions.

Lewis

Dec 18, 2025

Top 10 Supply Chain Management Software for Small Businesses

See the top 10 supply chain management software comparison for small businesses in 2026. Compare features, pricing, and scalability to find your best fit.

Lewis

Dec 18, 2025