Supply chain risk affects you when unexpected events disrupt the flow of goods, services, or information. Recent years have shown just how vulnerable global supply chains can be. You might notice delays or shortages after extreme weather, labor strikes, or even cyberattacks. The table below shows common causes and their impact:

| Cause of Disruption | Impact on Supply Chain |

|---|---|

| Geopolitical Events | Trade wars and political instability can lead to increased tariffs and sourcing challenges. |

| Natural Disasters and Climate Change | Events like earthquakes and floods can halt production and create global shortages. |

| Pandemics and Health Crises | COVID-19 caused factory closures and labor shortages, leading to significant delays in manufacturing. |

| Cybersecurity Threats | Cyberattacks can disrupt operations and compromise critical systems. |

| Labor Disruptions | Strikes can delay shipments and increase production costs, as seen in recent labor strikes in 2023. |

| Financial and Organizational Instability | Bankruptcies can cause cargo to be stranded, leading to widespread operational issues. |

| Technological Failures | Breakdowns in technology can halt production lines and disrupt information flow. |

| Supply Shortages and Raw Material Disruptions | Companies stockpile inventory to mitigate risks of shortages. |

| Logistics Risks | Shipping disruptions and port closures have been significant issues in recent years. |

You have likely felt the effects of these disruptions. For example:

You face supply chain risk when unexpected events threaten the smooth flow of goods, services, or information in your business network. Experts describe supply chain risk as the chance that something will go wrong and disrupt your operations. Wagner and Bode define it as the negative deviation from what you expect in performance, which can hurt your company. Waters explains that any hazard capable of disrupting logistics flows counts as supply chain risk, and these disruptions often have effects that reach far beyond the first problem.

Zsidisin describes supply risk as "the probability of an incident associated with inbound supply from individual supplier failures or the supply market occurring, in which its outcomes result in the inability of the purchasing firm to meet customer demand or cause threats to customer life and safety."

You can see that supply chain risk covers a wide range of threats. These include supplier failures, natural disasters, political events, and even cyberattacks. When you experience supply chain risk, you may find it hard to get the materials or products you need, which can lead to delays, higher costs, or lost sales.

Industry experts highlight several key components that define supply chain risk management. You need to understand these to protect your business:

| Key Component | Description |

|---|---|

| Structured Risk Assessment | A formal process for managing risk that involves multiple stakeholders. |

| Cross-Functional Collaboration | Involvement of various departments such as finance, operations, and risk management. |

| Continuous Monitoring | Ongoing assessment and adaptation to dynamic risks throughout the supply chain lifecycle. |

You should also involve subject matter experts from sourcing, manufacturing, and logistics. Senior management and key stakeholders must engage in the process. Integrating your risk management with suppliers and customers helps you spot problems early and respond quickly. Continuous monitoring and adaptation are crucial, as they let you react to new risks as soon as they appear.

You have seen many real-world examples of supply chain risk in recent years. These events show how quickly disruptions can spread across the globe and affect businesses and consumers alike.

These examples highlight how supply chain risk can come from many sources. You might face risks from political events, health crises, labor disputes, or environmental changes. Each event teaches important lessons. Businesses have learned to stay flexible, diversify suppliers, and invest in technology for better visibility. You can reduce your exposure to supply chain risk by building a balanced inventory strategy and considering local or near-shore production.

Note: Supply chain risk refers to the potential disruption or unavailability of resources from external suppliers, leading to disruptions in business operations.

When you understand supply chain risk and learn from these examples, you can better prepare your business for the unexpected.

You face many types of supply chain risk in your business. Each type can disrupt your operations in different ways. Understanding these risks helps you prepare and respond quickly. The table below shows the most common types of supply chain risk and their descriptions:

| Risk Type | Description |

|---|---|

| Environmental Risks | Storms, floods, and wildfires can damage factories and delay shipments. Extreme weather events threaten transport routes and block access to raw materials. Changing environmental regulations can slow production or raise costs. |

| Operational Risks | Breakdowns in equipment, poor supplier relationships, and internal mismanagement create operational risks that slow things down. A late shipment or a bad production batch can delay an entire order. |

| Financial Risks | Currency swings, payment failures, and weak supplier finances fall under financial risks. Global inflation or price hikes in materials increase the cost of doing business. |

| Geopolitical and Regulatory Risks | Political instability, sanctions, or shifting trade laws create delays and increase costs. A policy change can shut down exports or block critical parts at customs. |

| Demand and Supply Imbalances | A sudden sales surge or supply shortage throws plans off balance. Without real-time data, companies either stock out or over-order, tying up cash in excess inventory. |

Operational risks often come from inside your organization. You might see these risks when equipment breaks down or when employees make mistakes. Poor communication between departments can also cause problems. Sometimes, external events like natural disasters add to these risks. You may notice issues such as:

You need to watch for these risks in planning, supplier networks, and logistics systems. If you do not address operational risks, you may face delays, lost sales, or unhappy customers.

Financial risks can hit your supply chain in many ways. You might deal with sudden changes in currency values or payment failures from partners. Sometimes, suppliers face financial trouble and cannot deliver goods. Other times, global inflation or rising material costs increase your expenses. Common financial risks include:

You must monitor your finances closely. If you ignore financial risks, you may struggle to pay suppliers or keep your business running smoothly.

Geopolitical risks come from political events and changes in laws. Trade wars, sanctions, and new regulations can disrupt your supply chain. You may see higher costs or delays when countries change their trade policies. Some recent geopolitical events have caused:

You need to stay alert to global news and policy changes. By understanding geopolitical risks, you can adjust your supply chain strategy and reduce the impact on your business.

You face environmental risks in supply chain risk when natural events or climate changes disrupt your operations. These risks can stop production, delay shipments, and increase costs. You might see the effects of environmental risks in many ways:

Climate risks such as flooding, drought, and wildfire can cause delays and reduce profits. Experts estimate that environmental risks in supply chains could cost up to USD 120 billion by 2026. By the middle of this century, climate disruptions might result in as much as $25 trillion in net losses worldwide.

Environmental risks do not just come from nature. You also need to consider how these risks connect to social, economic, and political issues. For example, new environmental regulations can slow production or raise costs. Sometimes, market supply and demand risks appear when material deliveries get delayed or miscalculated.

You must monitor environmental risks closely. If you prepare for these risks, you can reduce their impact on your supply chain and keep your business running smoothly.

Cyber risks have become a major part of supply chain risk. As you rely more on digital systems and data sharing, your supply chain becomes more vulnerable to cyber threats. These risks can disrupt your operations and expose sensitive information.

You should watch for these common cyber risks in supply chain management:

You need to protect your supply chain from cyber risks by training your staff, securing your systems, and monitoring your partners. When you address cyber risks, you help ensure the safety and reliability of your entire supply chain.

You have seen how global events can quickly cause supply chain disruptions. Over the past five years, several major incidents have shown why you must pay close attention to supply chain risk. The table below highlights some of the most significant disruptions and their effects:

| Disruption | Description | Impact on Supply Chains |

|---|---|---|

| COVID-19 Pandemic (2020–2022) | Global lockdowns and production halts due to the pandemic. | Port congestion, labor shortages, and factory shutdowns led to critical stock shortages and a surge in freight rates. |

| Russia-Ukraine War (2022–Present) | Invasion of Ukraine causing sanctions and disruptions. | Energy prices soared, grain exports halted, and logistics networks compromised, affecting supply chains significantly. |

| Suez Canal Blockage (2021) | A container ship blockage that delayed over 400 ships. | $9.6 billion worth of goods delayed per day, causing significant disruptions in Europe-Asia trade. |

| U.S.-China Trade War (2018–2020) | Tariffs imposed on Chinese imports leading to retaliatory measures. | Cost spikes in consumer electronics and machinery, with a shift in manufacturing to other countries. |

These events show that supply chain disruptions can happen suddenly and have far-reaching effects. You need to prepare for the unexpected to protect your business from supply disruption.

Modern supply chains have become more complex and interconnected than ever before. You now rely on a web of suppliers, partners, and customers across the globe. This complexity increases the chance that a single problem can ripple through the entire network. Consider these factors:

You must recognize that supply chain risk grows as your network expands. A disruption in one area can quickly impact many others.

Today’s consumers expect fast, reliable service and product availability. You face pressure to deliver goods quickly and keep inventory levels just right. These rising expectations have changed how you manage supply chain risk. Key trends include:

You must adapt your supply chain to meet these demands. If you fail to respond, you risk losing customers and falling behind competitors. Supply chain disruptions can damage your reputation and bottom line, making proactive risk management more important than ever.

You experience the effects of supply chain risk in many areas of your business. Disruptions can halt production, delay shipments, and increase costs. When the COVID-19 pandemic struck, 94% of Fortune 1000 companies faced supply chain challenges by February 2020. Small businesses struggled with mass layoffs and closures. The World Trade Organization projected a drop in world trade between 13% and 32% in 2020. You may see these impacts in your daily operations:

You must monitor your supply chain closely to avoid these problems and keep your business running smoothly.

Supply chain risk does not just affect businesses. You feel the impact as a consumer, too. When disruptions occur, you may notice:

You expect fast service and reliable products. When companies cannot deliver, you lose trust and may look elsewhere for your needs.

Supply chain risk can ripple through the entire economy. Disruptions slow down production and increase costs for many industries. The following table shows how these risks affect economic growth and activity:

| Key Findings | Economic Impact |

|---|---|

| Supply chain disruptions during COVID-19 | Severe effects on economic growth |

| Role of supply chain networks | Transmission of economic shocks across regions |

| Decreased production and increased costs | Significant economic repercussions |

| International shocks during the pandemic | Affected economic activity in the U.S. |

| GDP decline attribution | 30% from foreign lockdowns, 70% from domestic disruptions |

| Lockdowns worldwide | Production stalled and delivery delays |

| GDP decline analysis | Quantifies impact of domestic vs. international factors |

You see that supply chain risk can cause GDP to fall and slow down recovery. Both domestic and international disruptions play a role. When you understand these impacts, you can better prepare your business and respond to challenges.

You need a structured approach to supply chain risk management if you want to protect your business from disruptions. The first step is to identify and assess risks across your entire supply chain. You can use several proven methods to do this effectively.

You can also use risk matrices to visualize and categorize risks. Risk modeling gives you quantitative estimates, while expert judgment adds qualitative insights. Scenario analysis helps you plan for different types of disruptions. Advanced techniques like AHP, TOPSIS, and ANP let you rank risks, and quantitative tools such as CVaR and Mean–Variance help you measure risk exposure.

Supply chain mapping solutions, environmental risk tools, and code verification systems can support your risk identification process. These tools give you a clear view of your supply chain and help you spot weak points before they become major problems.

Tip: Always integrate risk management into your daily operations. This makes it easier to spot issues early and respond quickly.

You build supply chain resilience by preparing for disruptions and responding quickly when they happen. Supply chain risk management focuses on making your network strong enough to handle shocks and flexible enough to recover fast.

Follow these steps to strengthen your supply chain resilience:

You should measure the effectiveness of your supply chain risk management strategies. Use metrics like time-to-survive, time-to-recover, and time-to-thrive. These show how long your business can operate during a disruption, how quickly you can return to normal, and how fast you can take advantage of new opportunities after recovery.

| Metric | Description |

|---|---|

| Resilience Measurement | Companies that track their response to disruptions are 3.4 times more likely to report strong supply chain resilience. |

| Survey Agreement | 55% of organizations with clear response metrics strongly agree on their resilience, compared to 16% without metrics. |

You can also estimate potential revenue loss if you lose a supplier or material. This helps you decide where to focus your risk management efforts.

Note: The more you measure and monitor your supply chain risk management, the better you can respond to new threats and protect your business.

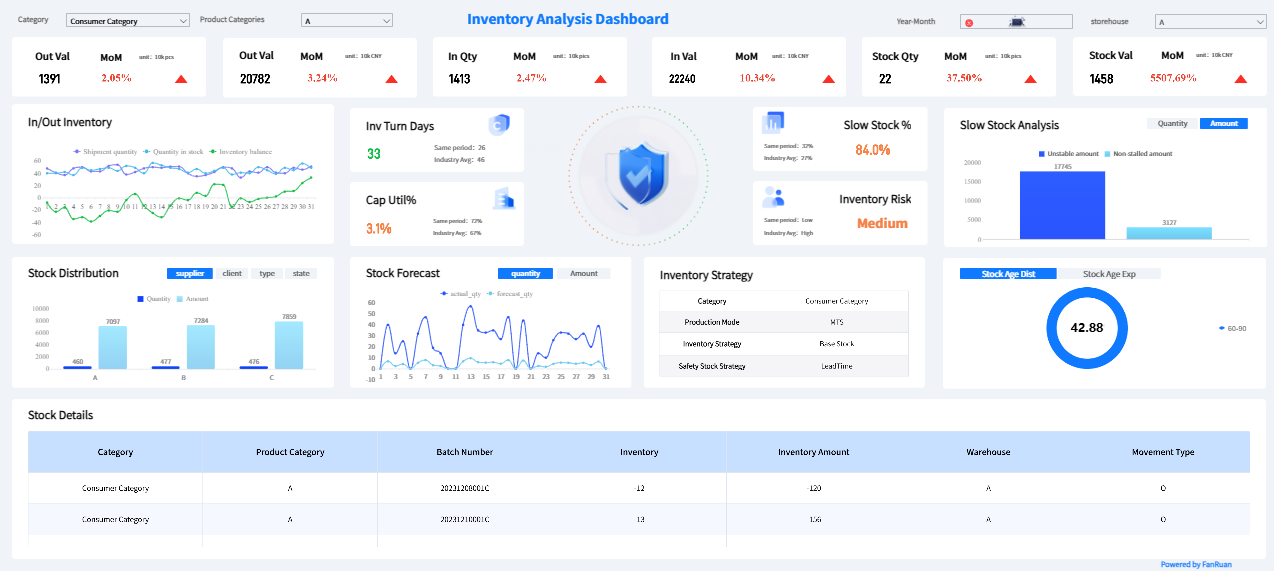

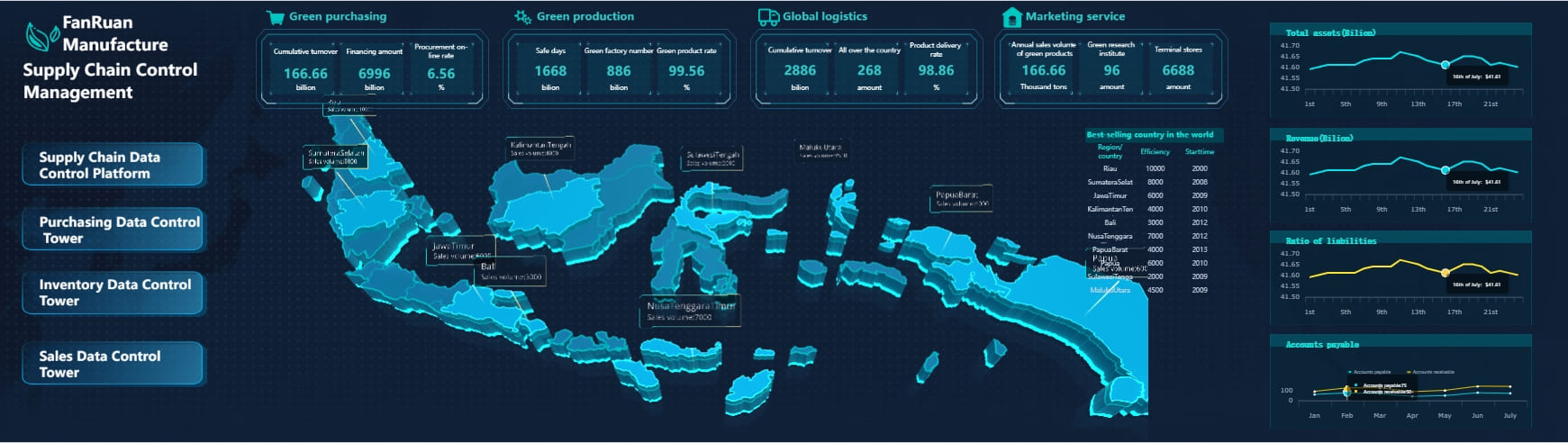

Technology plays a vital role in modern supply chain risk management. You need real-time data and advanced analytics to spot risks early and make informed decisions. FineReport gives you the tools to integrate, visualize, and analyze your supply chain data on a single platform.

FineReport connects to systems like ERP, MES, and SRM. This integration brings all your supply chain information together, breaking down data silos. The low-code functionality makes it easy to set up and customize, even if you do not have deep technical skills.

With FineReport, you can create dashboards that show key risk indicators, supplier performance, and inventory levels. Data visualization helps you see patterns and trends, making it easier to identify issues before they escalate. You can use predictive analytics to anticipate interruptions and develop plans to reduce risk.

| Feature | Description |

|---|---|

| Data Integration | FineReport brings together data from multiple systems for real-time insights. |

| Low-Code Functionality | Simplifies integration and customization, eliminating data silos. |

| Data Visualization | Consolidates information into interactive dashboards for easy analysis and decision-making. |

Data analytics with FineReport offers several benefits for supply chain risk management:

You can transform data into valuable insights, detect new risks like cyber threats, and improve your decision-making. FineReport helps you keep your supply chain risk management proactive and effective.

Remember: Leveraging technology like FineReport strengthens your supply chain risk management and supports your business in a rapidly changing world.

You cannot manage supply chain risk effectively without strong collaboration and clear communication. When you work closely with your supply chain partners, you build a network that can spot problems early and respond quickly. This approach helps you reduce the impact of disruptions and keep your business running smoothly.

Collaboration in supply chain risk management means sharing information, resources, and expertise with your suppliers, customers, and other partners. You do not work in isolation. Instead, you create a team that can handle challenges together. When you collaborate, you gain several important benefits:

Communication plays a key role in managing supply chain risk. You need to keep everyone informed and engaged. Effective communication strategies help you build trust and solve problems quickly. Consider these best practices:

You should remember that collaboration and communication are not one-time tasks. You need to make them part of your daily operations. Regular meetings, shared dashboards, and open feedback channels help you stay connected with your partners. When you focus on these areas, you strengthen your ability to manage supply chain risk and protect your business from unexpected events.

After you establish strong collaboration and communication practices, you can take your supply chain risk management to the next level with technology. FineReport offers powerful tools that support real-time data sharing, interactive dashboards, and seamless integration with your existing systems. With FineReport, you can visualize your entire supply chain, monitor risks as they emerge, and keep all stakeholders informed. This technology makes it easier to maintain transparency, coordinate responses, and build a resilient supply chain network.

Recognizing supply chain risk helps you build resilience and maintain consumer trust. When you manage risks proactively, you adapt quickly to disruptions, save costs, and deliver products consistently.

Tools like FineReport support your efforts by automating reporting, improving data accuracy, and providing clear dashboards. Staying ahead of supply chain risk ensures smoother operations and long-term success for your business.

What is Supply Chain Risk Management Process and How It Work

What is Supply Chain Visibility and Why Does It Matter

Supply Chain Analytics Explained and Its Importance

What is Predictive Analytics in Supply Chain Management

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

9 Best Supply Chain Tools for Smarter Management in 2026

Find the best supply chain tools for 2025 to boost efficiency, gain real-time insights, and achieve smarter management for your business.

Lewis

Dec 18, 2025

Top 10 Supply Chain Tracking Software for 2026

Compare the top supply chain tracking software for 2026 to boost visibility, automate workflows, and leverage AI analytics for smarter decisions.

Lewis

Dec 18, 2025

Top 10 Supply Chain Management Software for Small Businesses

See the top 10 supply chain management software comparison for small businesses in 2026. Compare features, pricing, and scalability to find your best fit.

Lewis

Dec 18, 2025