Supply chain automation uses technology to streamline and optimize your supply chain tasks, making your business more efficient and competitive. You can see real results across industries: a national automotive distributor cut operational costs by 25%, while a fashion company reduced overstock by 30% and increased revenue by 20%. Automation helps you manage inventory, improve forecasting, and reduce errors. Tools like FineReport let you connect data, automate reporting, and gain real-time insights, transforming how you operate and make decisions.

Supply chain automation uses technology to streamline and optimize every step of your supply chain. You rely on automation to reduce manual work, improve accuracy, and speed up processes. Automation in supply chains covers a wide range of activities, from inventory management to order fulfillment. You can use automation tools to track shipments, manage vendors, and process orders with minimal human intervention.

Note: Supply chain automation is not limited to large enterprises. Small and medium-sized businesses also benefit from automation technology, which helps them compete more effectively.

You see supply chain automation in action when you use software to monitor inventory levels or automate order processing. Automation tools help you avoid errors and delays, making your supply chain more reliable. Business automation also improves communication between departments, ensuring everyone has access to the same real-time data.

Here is a table showing the core components and processes involved in supply chain automation:

| Component/Process | Description |

|---|---|

| Inventory Management | Automates tracking and managing inventory in real-time, reducing human error and improving efficiency. |

| Order Processing and Fulfillment | Streamlines order processing, ensuring accurate and timely deliveries through automation software. |

| Transportation and Logistics | Uses digital tools for tracking deliveries and improving logistics efficiency. |

| Vendor Management | Automates procurement and vendor relationships, streamlining selection and performance tracking. |

You can also look at the most common supply chain processes automated by businesses today:

| Process Type | Description |

|---|---|

| Warehouse automation | Enhances efficiency in inventory storage and order fulfillment through software solutions. |

| Inventory automation | Improves visibility and accuracy of inventory data, ensuring efficient warehouse operations. |

| Back-office automation | Streamlines data entry and provides real-time business insights, reducing human error. |

| Transport & logistics automation | Facilitates delivery tracking and communication between transport teams for faster deliveries. |

You implement supply chain automation by integrating digital systems and automation technology into your existing processes. Automation in supply chains relies on software, sensors, and data analytics to handle repetitive tasks and provide real-time insights. You start by identifying which processes need improvement, such as inventory tracking or order fulfillment.

Here is a step-by-step approach to how supply chain automation works:

Tip: When you automate your supply chain, you gain better visibility and control over every stage, from procurement to delivery.

Process automation begins with assessing your current needs. You analyze your supply chain to find areas where automation can make the biggest impact. You then select the right automation tools and technologies that fit your business goals. Training your staff and integrating new systems are key steps in successful implementation.

Here is a table outlining the main steps in implementing supply chain automation:

| Step | Description |

|---|---|

| Assessing Needs | Conduct an analysis of current processes, define goals, and involve stakeholders for buy-in. |

| Selecting Solutions | Research and compare automation technologies based on capability, cost, and integration. |

| Training and Integration | Develop a change management plan, train staff, and integrate automation incrementally. |

You evaluate the automation process regularly to ensure it meets your objectives. You adjust your strategy as needed to maximize efficiency and cost savings. Automation technology continues to evolve, so you stay updated on new tools and trends to keep your supply chain competitive.

Supply chain automation relies on several advanced technologies that work together to transform how you manage your operations. When you explore automation in supply chains, you see the impact of software solutions, robotics, IoT devices, and artificial intelligence. Each technology plays a unique role in streamlining processes, improving accuracy, and enabling real-time tracking.

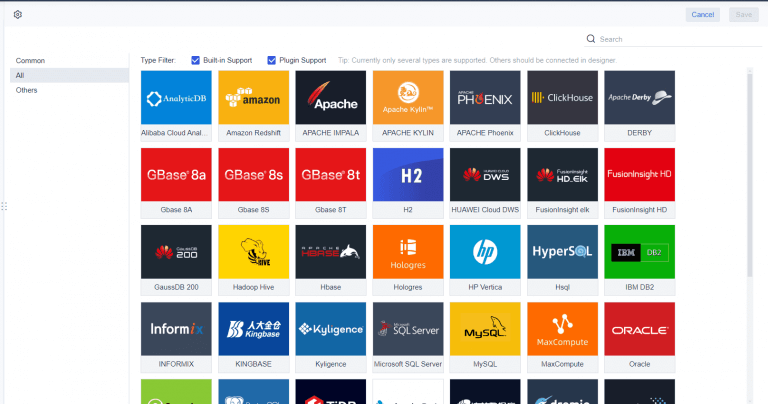

You use software solutions as the backbone of supply chain automation. These platforms help you manage data, automate reporting, and support decision-making. Leading inventory management software and business automation tools offer features like real-time visibility, workflow automation, and seamless integration with other systems. Here is a comparison of top platforms:

| Platform | Key Capabilities | Deployment Type | Best Suited For |

|---|---|---|---|

| SAP SCM | Real-time supply-demand alignment, advanced analytics, vertical-specific modules | On-premise & Cloud | Manufacturing, pharma, automotive |

| Oracle SCM Cloud | End-to-end visibility, AI-driven planning, scalable for global operations | Cloud-only | Large-scale global supply operations |

| Microsoft Dynamics 365 SCM | Predictive insights, IoT-enabled tracking, ERP integration, workflow automation | Cloud-first, hybrid | Mid to large businesses with MS stack |

| Blue Yonder | Demand sensing, real-time execution, scenario-based planning | Cloud-first | Retail, logistics, distribution |

| Infor SCM | End-to-end planning, workflow automation, industry-focused solutions | Cloud & On-premise | Manufacturing, distribution-heavy sectors |

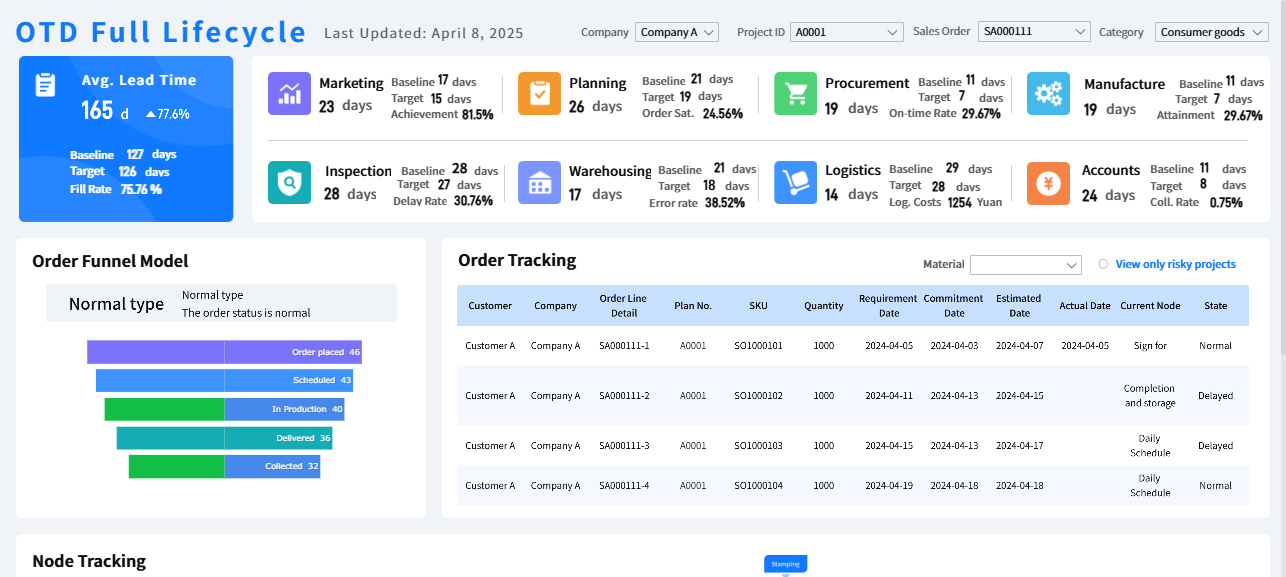

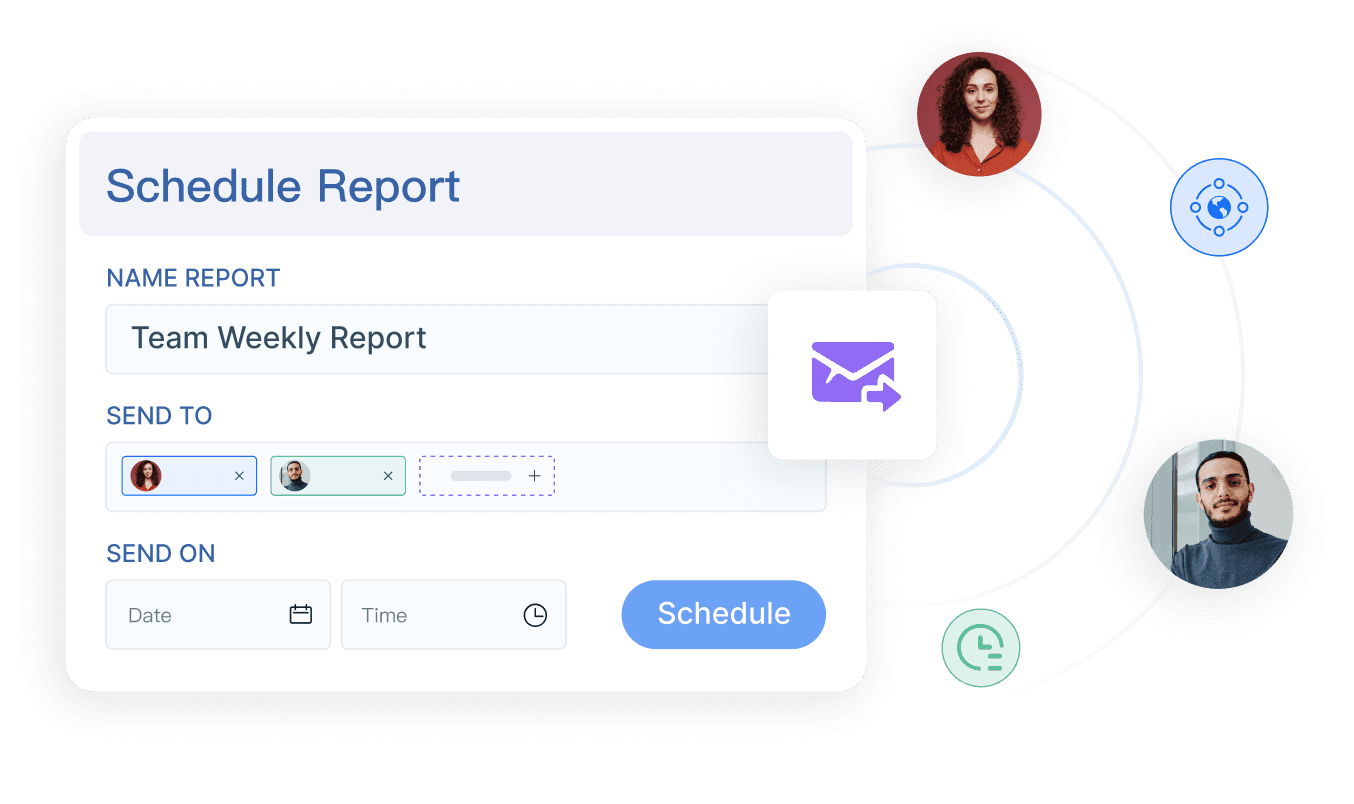

FineReport stands out as a flexible reporting and dashboard tool. You can connect data from multiple sources, automate report generation, and create interactive dashboards. FineReport supports process automation by integrating procurement, inventory, and sales data. In manufacturing, you gain real-time insights and control over your supply chain, improving efficiency and supporting strategic decisions.

You see robotics and IoT devices driving automation in supply chains by:

These automation tools help you respond quickly to changes and maintain a competitive edge.

Artificial intelligence takes supply chain automation to the next level. You benefit from:

The use of technology like AI ensures your supply chain remains agile and resilient in a fast-changing market.

You experience significant efficiency gains when you implement supply chain automation. Automation in supply chains reduces manual errors and speeds up routine tasks, allowing you to focus on higher-value activities. Many companies report measurable improvements after adopting automation tools. For example, you can cut operating expenses by as much as 50%. Businesses often see cost reductions of up to 70%, with manufacturing firms saving around 25% and logistics companies saving 30%. A well-executed business automation project can save millions by handling tasks that once required hundreds of employees.

Here is a table showing the impact of automation on key metrics:

| Metric | Impact |

|---|---|

| Revenue Growth | 74% of users reported increased revenue within 3 months |

| Stock Management | 96% fewer out-of-stock issues |

| Operational Efficiency | 89% reduction in future staffing needs |

| Time Savings | Up to 50% less time spent on buyer tasks |

You also benefit from optimized resource allocation, which reduces material waste and labor costs. Automation benefits extend to faster workflows and improved responsiveness, helping your business stay competitive.

Automation gives you real-time data insights into every part of your supply chain. You gain real-time production visibility, which helps you track inventory, shipments, and orders without relying on manual reporting. Smart tags and GPS technology improve asset tracking, providing accurate location data at all times. Centralized digital data makes it easier for you to monitor supply chain movements and respond quickly to changes.

| Evidence Description | Source |

|---|---|

| Automation reduces manual reporting, enhancing efficiency and accuracy in data visibility. | Silq |

| Smart tags and GPS improve asset tracking, providing real-time location data. | Silq |

| Centralized digital data is essential for developing supply chain visibility. | Perfect Planner |

| Centralizing data allows for real-time visibility into supply chain movements. | Tungsten Automation |

You use automation tools to collect and analyze data, which supports better demand forecasting and decision-making. Enhanced visibility means you can identify bottlenecks and address issues before they affect your operations.

You see supply chain automation transforming industries through successful real-world applications. A major auto manufacturer uses automated dispatch solutions to match assets and assign orders in real time. Kimberly-Clark analyzes shipment patterns with advanced automation, improving load management and cutting transportation costs. Associated Food Stores deploys AI-enabled robotics to enhance picking operations and boost efficiency in their distribution centers.

Tip: When you measure the return on investment for automation projects, you look at both hard factors like labor savings and soft factors such as improved sales response. A strong business case with clear ROI analysis helps you justify automation investments and build consensus among stakeholders.

Automation benefits include improved efficiency, cost reduction, enhanced decision-making, and greater visibility. You can track these gains using quantifiable metrics and see the impact across different sectors.

You face several barriers when you begin supply chain automation. The most common obstacles include technology adoption, collaboration issues, and poor data management. Many organizations struggle with integrating new systems into existing workflows. You may encounter compatibility problems, high initial costs, and resistance from employees. The following table shows the most frequent barriers:

| Barrier Type | Percentage (%) |

|---|---|

| Challenges related to implementing new technology | 52 |

| Lack of collaboration | 50 |

| Poor data management practices | 48 |

System compatibility can disrupt operations and create inefficiencies. You should prioritize selecting compatible platforms and invest in unified solutions to reduce these issues. High upfront costs often deter businesses from automation, but a thorough cost-benefit analysis helps justify the investment. Workforce transition also presents challenges. You need to upskill employees and communicate openly to foster a positive attitude toward automation.

FineReport supports seamless integration with various data sources and business systems. You can connect databases, spreadsheets, and external platforms, reducing compatibility concerns. The software’s flexible architecture streamlines implementation and minimizes operational disruptions.

Automation transforms workforce roles in supply chain management. You see companies investing in warehouse automation, such as autonomous robots and automated storage systems, to address labor shortages. This shift allows you to maintain efficiency with fewer workers while meeting demand for speed and accuracy.

| Impact of Supply Chain Automation on Workforce Roles | Description |

|---|---|

| Creation of New Job Functions | Automation leads to roles focused on technology and data management. |

| Necessity for Upskilling and Reskilling | You must invest in training to help employees adapt to new technologies. |

| Reduction of Low-Skilled Positions | Automation decreases the need for low-skilled jobs and increases demand for high-skilled roles. |

| Increased Flexibility in Roles | Automation enables remote work and flexible hours in areas like data analysis and AI development. |

You notice that automation and AI make repetitive roles less common. Workers who embrace new technologies can leverage their experience to grow within your organization. FineReport's intuitive interface and low-code environment simplify training and support workforce transition.

Data security remains a top concern when you implement supply chain automation. You must protect customer data and ensure secure data transfer during logistics automation. Companies address these risks by using multiple layers of security, end-to-end encryption, and access control systems. Regular security audits and penetration testing help identify vulnerabilities. Strong vendor partnerships and compliance with security protocols further reduce risks. You should also provide employee training focused on practical security scenarios.

Automation introduces risks such as logistics disruptions, lack of transparency, and cybersecurity threats. You can mitigate these risks by building strong supplier relationships, implementing dynamic freight management, and using advanced technologies like AI and blockchain for tracking and transparency.

FineReport offers robust security management features. You control user permissions, schedule regular audits, and ensure secure data handling. The platform’s centralized management helps you maintain compliance and protect sensitive information throughout your supply chain management processes.

You can begin automating your supply chain by following a clear, step-by-step approach. Supply chain automation works best when you start with a thorough assessment and move forward with careful planning. Here is a recommended process automation roadmap:

When selecting automation technology, you should consider several factors:

Change management plays a crucial role. Companies like General Electric and Unilever have shown that early involvement of managers, hands-on training, and clear communication help ensure a smooth transition to automation.

Supply chain automation continues to evolve rapidly. Over the next decade, you will see several trends shaping the future:

| Trend | Description |

|---|---|

| Hyperautomation | AI and RPA automate entire supply chains, reducing human intervention and boosting efficiency. |

| Real-time Data Integration | Immediate access to data enables proactive management and faster decision-making. |

| Robotics and IoT | Innovations improve warehouse operations and last-mile logistics through automation technology. |

| Sustainability Initiatives | Automation helps reduce carbon footprints and ensures compliance with environmental standards. |

You will also notice more businesses using AI and IoT to gather data, predict challenges, and improve warehouse management. Companies like Danone have digitalized their supply chain planning, leading to faster decisions and better collaboration. Automated inventory management and advanced tracking will become standard, helping you respond quickly to market changes.

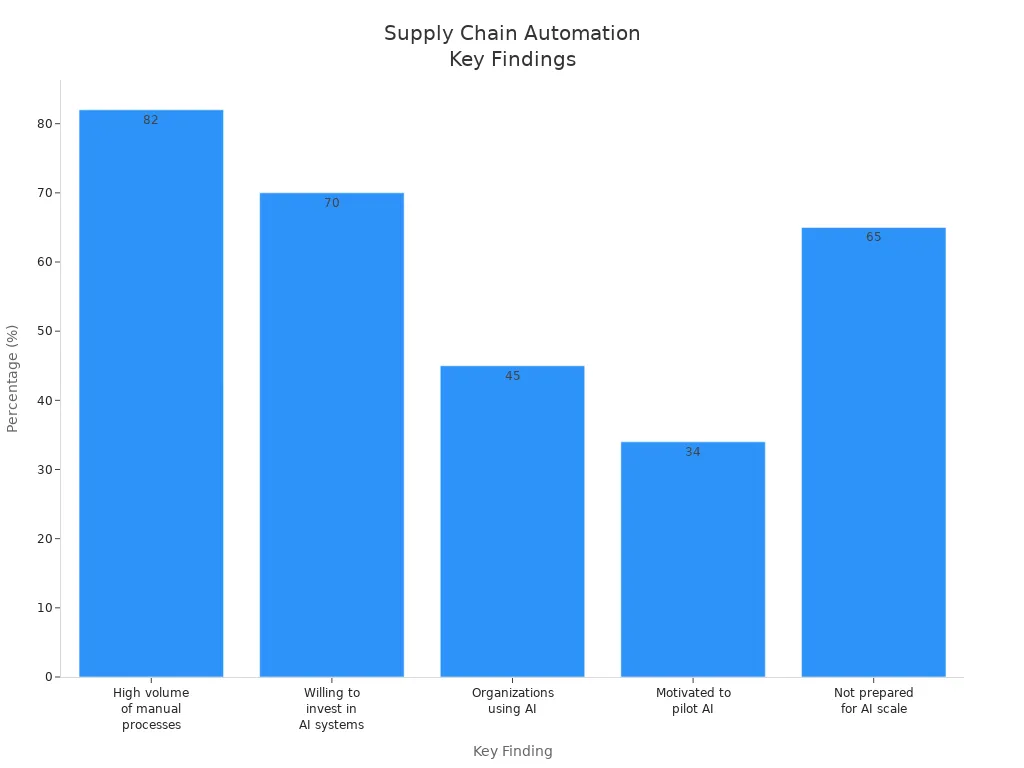

You have seen how supply chain automation transforms your operations, driving efficiency, visibility, and competitiveness. Automation streamlines manual tasks and supports supply chain optimization, making your business automation strategy more effective. Recent research shows that 82% of organizations still rely on manual processes, while 70% are ready to invest in AI-optimized systems.

| Key Finding | Percentage |

|---|---|

| High volume of manual processes still in use | 82% |

| Willing to invest in AI-optimized systems | 70% |

| Organizations currently using AI | 45% |

| Motivated to pilot AI solutions | 34% |

| Not fully prepared to implement AI at scale | 65% |

To get started, you should:

You can enhance your automation journey by consulting technology providers. Focus on technology integration, workforce transition, data security, continuous improvement, and collaboration. FineReport offers powerful tools to help you achieve supply chain automation success.

What is Supply Chain Risk Management Process and How It Work

Supply Chain Risk Explained and Why it Matters Now

What is Supply Chain Visibility and Why Does It Matter

Supply Chain Analytics Explained and Its Importance

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

9 Best Supply Chain Tools for Smarter Management in 2026

Find the best supply chain tools for 2025 to boost efficiency, gain real-time insights, and achieve smarter management for your business.

Lewis

Dec 18, 2025

Top 10 Supply Chain Tracking Software for 2026

Compare the top supply chain tracking software for 2026 to boost visibility, automate workflows, and leverage AI analytics for smarter decisions.

Lewis

Dec 18, 2025

Top 10 Supply Chain Management Software for Small Businesses

See the top 10 supply chain management software comparison for small businesses in 2026. Compare features, pricing, and scalability to find your best fit.

Lewis

Dec 18, 2025