A sustainable factory puts sustainability at the heart of every operation. You see the difference in how it manages energy, waste, and resources. Traditional manufacturing often leads to high energy use, harmful emissions, and large amounts of waste. A sustainable factory changes this by using renewable energy, minimizing pollution, and making the most of every material. These actions support sustainable development and help you meet your sustainability goals while protecting the environment for future generations.

When you step into a sustainable factory, you notice a clear focus on sustainability in every process. A sustainable factory uses green manufacturing to reduce its environmental impact and support sustainable development. You see the difference in how it manages resources, energy, and waste. Instead of following the old "take, make, dispose" model, a sustainable factory adopts green manufacturing practices that reuse, recycle, and repair materials. This approach helps protect the environment and ensures long-term business success.

You find that sustainable manufacturing goes beyond just using renewable energy. It includes responsible sourcing of materials, water conservation, and transparency in emissions. A sustainable factory also values social responsibility, making sure workers have safe conditions and fair treatment. By combining these efforts, you help create a workplace that supports both people and the planet.

Note: Sustainable manufacturing practices encourage you to set clear goals, monitor progress, and keep improving. This mindset helps your factory stay competitive and resilient in a changing world.

You can identify a sustainable factory by looking for several key features:

Here’s a quick comparison of operational practices:

| Operational Practice | Description |

|---|---|

| Resource Efficiency | You optimize materials, energy, and water to minimize waste. |

| Lean Manufacturing | You eliminate waste and streamline production for better efficiency. |

| Renewable Energy | You use solar, wind, or other renewables to power your facility. |

| Eco-Friendly Materials | You prioritize recycled or bio-based products. |

| Social Responsibility | You ensure worker safety and promote diversity. |

| Circular Economy Practices | You reuse, repair, and recycle to reduce raw material use and waste. |

| Cloud Technologies | You use cloud computing to improve energy efficiency and reduce emissions. |

By focusing on these features, you help your factory achieve green manufacturing goals and reduce environmental impact. Sustainable manufacturing practices not only benefit the environment but also drive innovation and efficiency. When you adopt green production and sustainable industrial production, you support a healthier environment and a stronger business.

You play a key role in shaping how your factory manages resources. Sustainable production starts with smart choices about raw materials and waste. In a sustainable factory, you select renewable, recyclable, and biodegradable materials. This approach supports green manufacturing by reducing waste and protecting natural resources. You move away from the old "take-make-dispose" model. Instead, you use circular economy principles. You keep materials in use longer by designing products for durability, repair, and recycling.

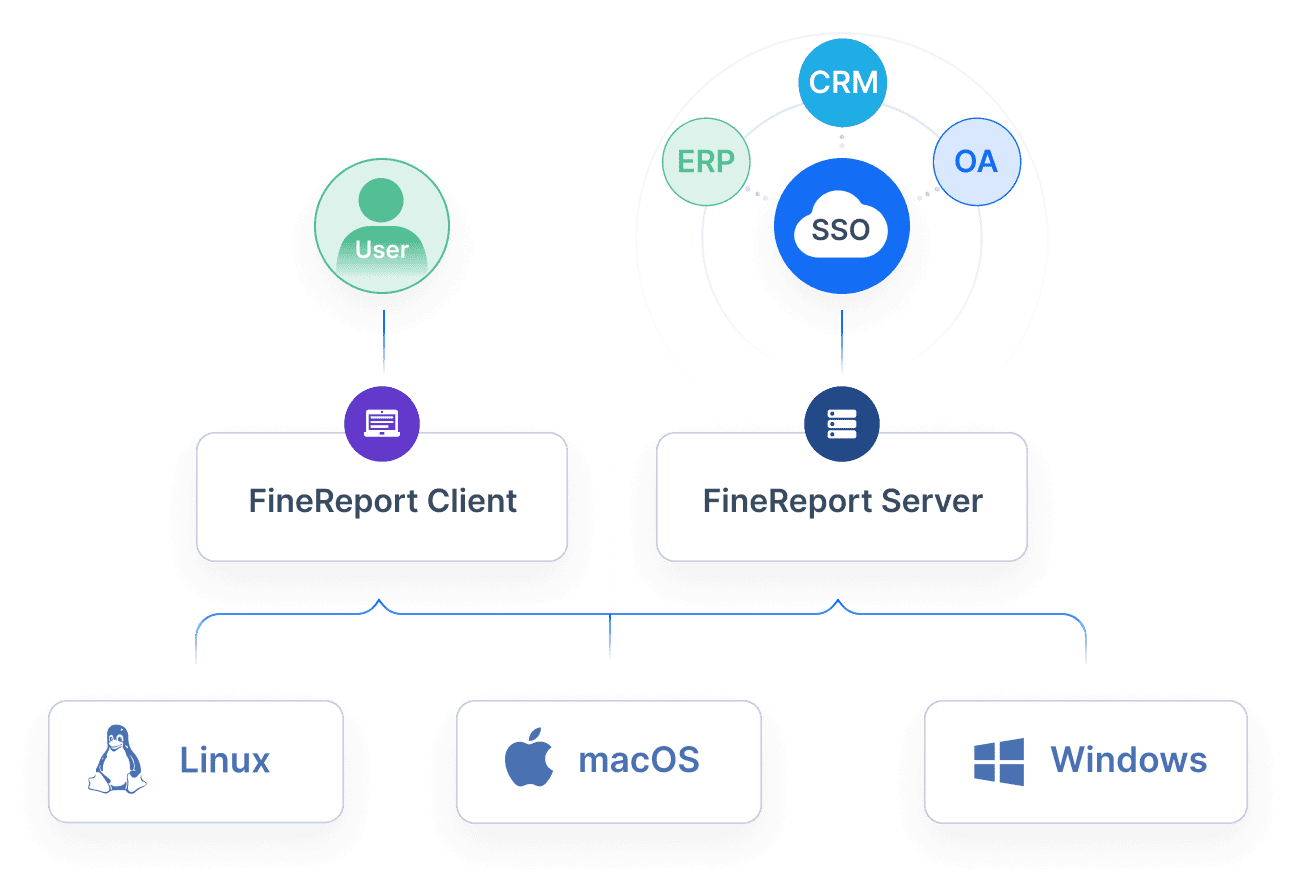

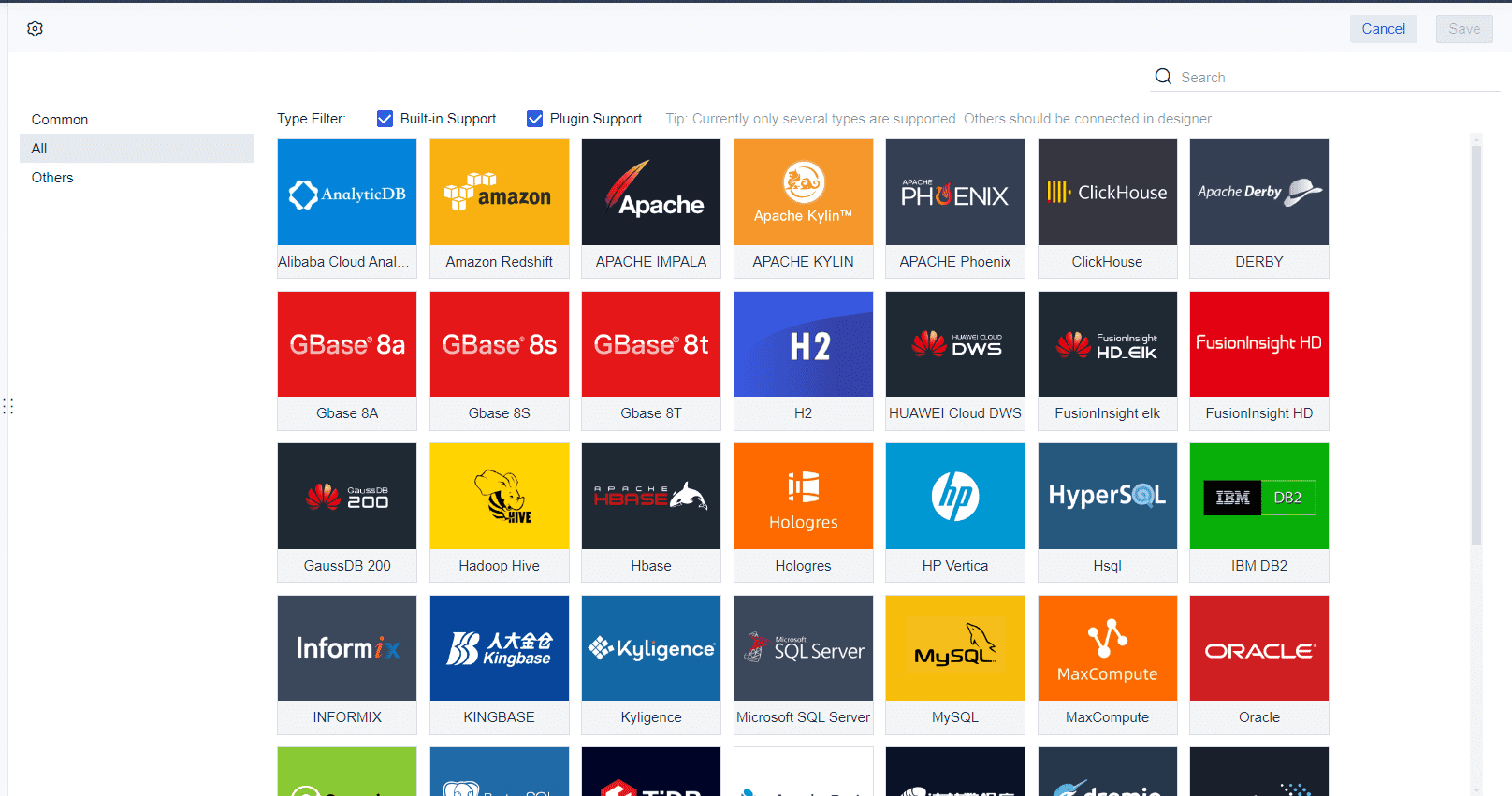

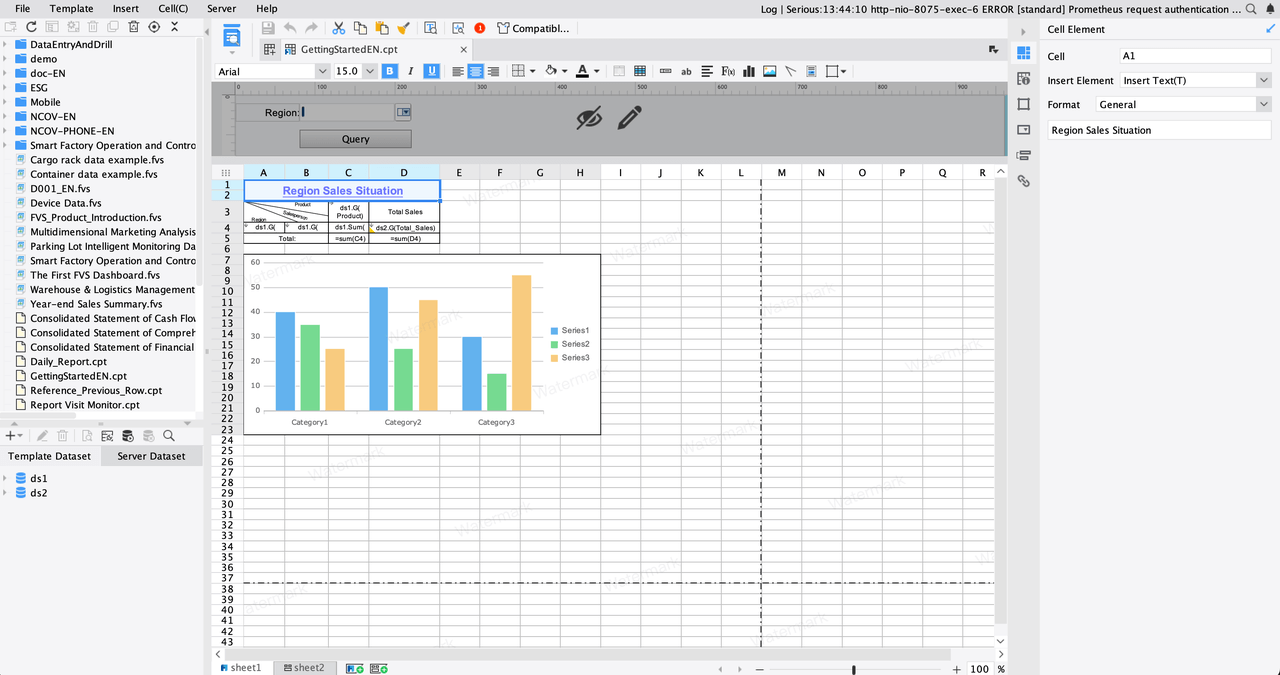

You also build a sustainable supply chain. You focus on ethical sourcing, lower emissions, and efficient logistics. These steps help you reduce your carbon footprint and improve cost-effectiveness. You can see the benefits in cost savings, resilience, and innovation. Sustainable manufacturing relies on advanced tools. You use digital platforms like FanRuan and FineReport to integrate data from suppliers, production lines, and warehouses. These tools help you track resource use, monitor waste, and optimize inventory in real time.

Tip: When you use FineReport, you can create dashboards that show material flow, waste levels, and recycling rates. This helps you spot problems early and make better decisions.

You also adopt lean production and agile manufacturing. These methods help you cut waste, streamline operations, and respond quickly to changes. You use real-time data to adjust production schedules and reduce excess inventory. By combining digital solutions with green manufacturing, you make your factory more sustainable and efficient.

You drive energy efficiency by using the latest technologies. In a sustainable factory, you install renewable energy systems like solar panels or wind turbines. These systems lower your reliance on fossil fuels and cut emissions. You also use waste heat recovery and cogeneration systems. These capture and reuse energy that would otherwise go to waste. For example, you might see a brewery reduce its natural gas use by 20% with waste heat recovery.

You rely on smart manufacturing tools to monitor and control energy use. Industrial IoT sensors and AI-powered analytics give you real-time insights. You can track energy consumption, spot inefficiencies, and adjust equipment settings. This approach supports green manufacturing by lowering energy intensity and improving operational efficiency. You also use advanced materials and closed-loop water recycling systems. These innovations help you save energy and reduce waste.

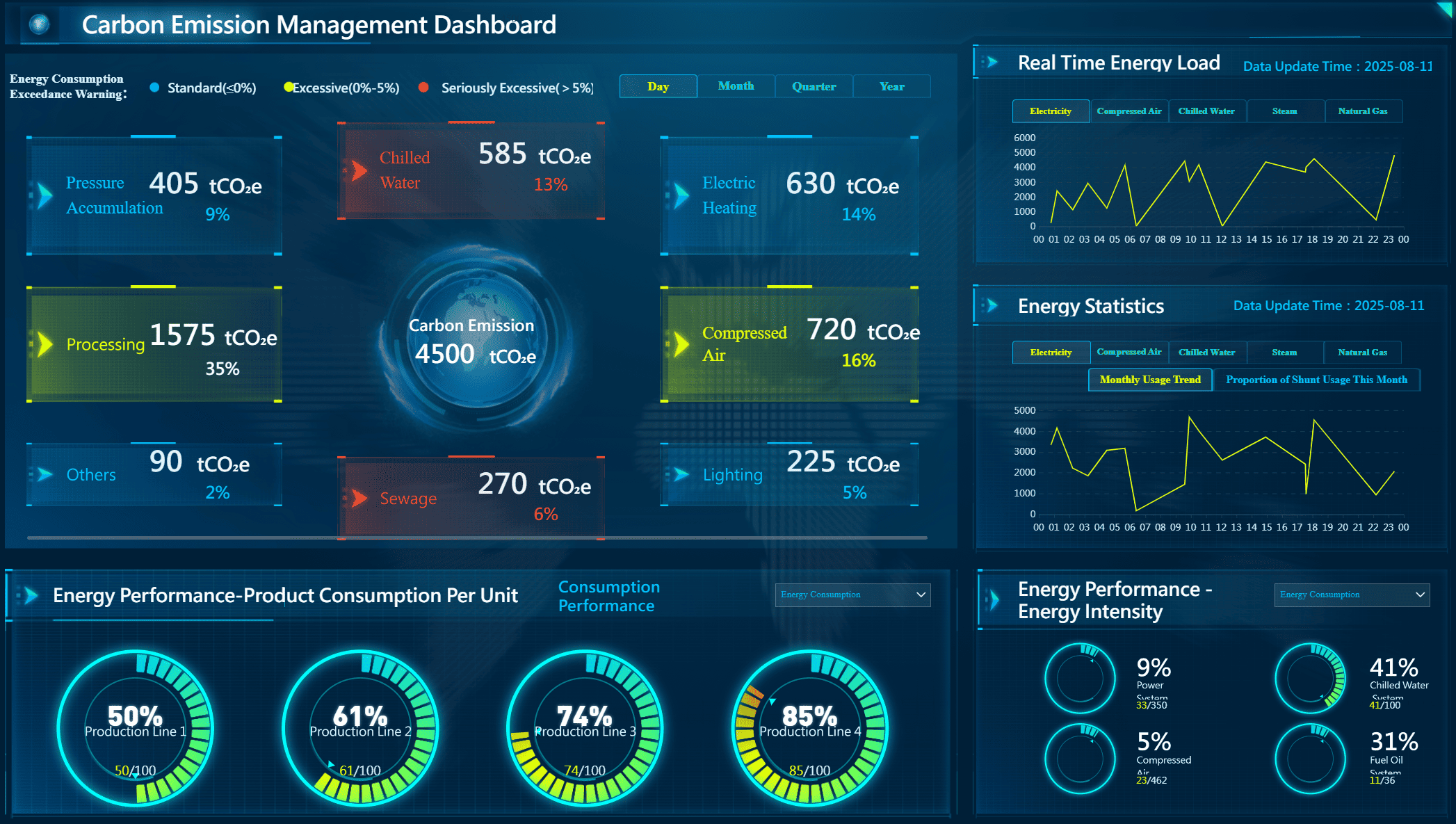

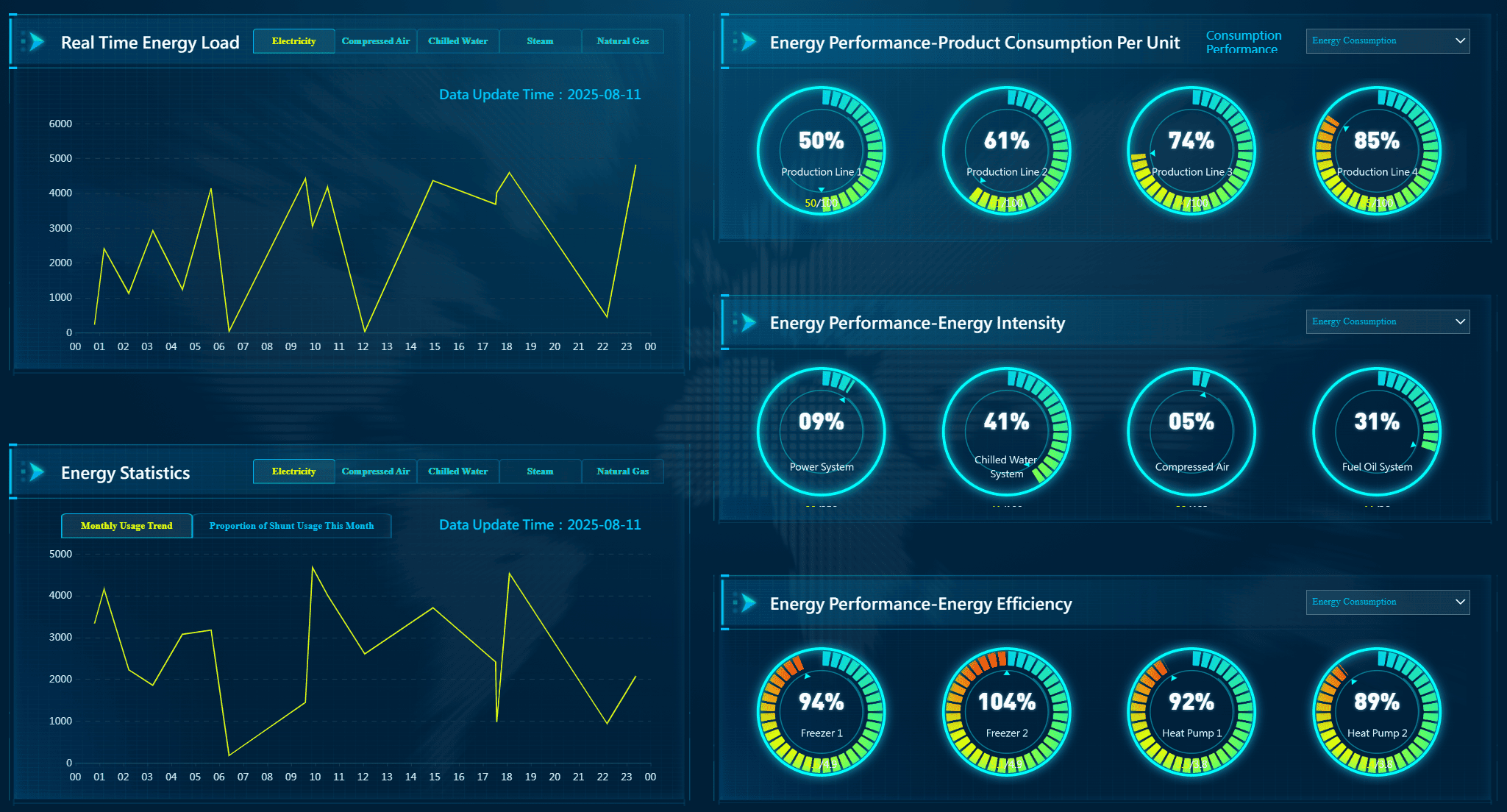

You can manage all this data with FineReport. The platform lets you build energy management dashboards. You see real-time energy use, compare it to targets, and find ways to improve. You can also schedule reports to track progress over time. This helps you meet your sustainability goals and prove your commitment to sustainable production.

Note: Many factories use high-performance insulation, LED lighting, and smart building systems. These upgrades lower energy costs and create a more comfortable workplace.

You embed energy efficiency into your company culture. You train your team to look for ways to save energy and support green manufacturing. You also explore new business models, like energy-as-a-service, to modernize your infrastructure without large upfront costs.

You know that a sustainable factory cares about people as much as the planet. You design workspaces that support health, comfort, and productivity. You use eco-friendly materials and systems that improve indoor air quality. You install energy-efficient lighting and equipment. These choices reduce environmental impact and create a healthier workplace.

You also focus on ergonomics and active design. You set up workstations that prevent injuries and encourage movement. You use acoustic design to lower noise and reduce stress. You control temperature and air flow to keep everyone comfortable. You add plants and natural materials to boost air quality and employee satisfaction.

You support sustainable habits with your policies. You encourage alternative commuting, remote work, and sustainability education. You run recycling programs and promote responsible waste management. These actions help build a culture of sustainability and green manufacturing.

You use digital EHS management systems, like those powered by FineReport, to track health and safety data. You monitor air quality, manage safety training, and report incidents in real time. This proactive approach helps you prevent accidents and improve well-being. You also use wearables and mobile apps to support contactless operations and monitor employee health.

Remember: When you invest in employee well-being, you see higher job satisfaction, better productivity, and a stronger reputation for your factory.

You measure your progress with clear KPIs. You track energy use, waste, emissions, and employee health. You use dashboards and reports to share results with your team and stakeholders. This transparency helps you stay accountable and keep improving your sustainable production practices.

You can manage your factory’s carbon footprint by using a dedicated carbon emission and energy consumption management module. This module helps you track and reduce emissions at every level of your operation. You see how leading factories, like LG Innotek’s Gumi plant, use renewable energy and recycle all scrap materials to achieve zero waste to landfill. Samsung’s factories use digital tools to monitor emissions and energy use, reaching over 93% renewable energy conversion at major sites.

Key components of this module include:

You use these tools to measure, report, and improve your sustainability performance. This approach supports best practices for sustainable production and helps you make informed investment decisions.

You monitor your factory’s energy use in real time with Industry 4.0 systems. These systems use IoT devices and web platforms to collect data on voltage, current, peak power, and energy costs. You do not need to change your existing equipment. The platform shows you real-time data, so you can spot problems and make quick decisions. Advanced analytics help you predict equipment failures and optimize resource use. You can track your carbon footprint and energy use, which helps you meet your sustainability goals.

You also benefit from performance monitoring software. This software turns raw data into useful information. You see energy use, water consumption, and waste in real time. The system alerts you to issues, so you can act fast. Integration with ERP and MES systems, along with AI and digital twins, makes your monitoring even smarter.

You use a power management dashboard to see all your energy data in one place. This dashboard displays key metrics such as:

The dashboard helps you compare actual energy use to targets. You can analyze trends, allocate costs by department, and track your carbon footprint. User-friendly interfaces and customizable views make it easy for you to focus on what matters most for your factory’s sustainability.

You rely on data integration to drive sustainable production in your factory. FineReport helps you connect data from different systems, such as ERP, MES, and SRM. You see all your information in one dashboard, which makes it easier to manage resources and track progress. You avoid data silos and reduce manual work. Automated reporting and customizable dashboards let you respond quickly to changes. You use real-time insights to guide your decisions and improve sustainable production. FineReport’s AI-driven alerts help you spot risks early. You can monitor supply chain performance and benchmark your results against industry standards.

Tip: FineReport’s user-friendly interface lets you create interactive reports and dashboards. You can drill down into data for deeper understanding and share insights across teams.

Here’s how FineReport improves your operations:

You use automation and smart systems to optimize sustainable production. Automated assembly lines work faster and use less material. Predictive maintenance keeps your machines running smoothly and prevents breakdowns. You install smart sensors and IoT devices to monitor energy and material use. These tools help you reduce waste and lower energy consumption. Robotics improve efficiency and safety, which supports sustainable production. You use inventory control software and AI analytics to avoid surpluses and prevent overproduction. Automated quality inspection detects defects in real time, reducing waste. Additive manufacturing lets you produce only what you need, minimizing material use.

Note: Automation supports circular economy practices. Robotic disassembly helps you recycle and reuse materials, lowering your need for new resources.

You benefit from:

You depend on real-time monitoring to achieve sustainable production goals. Sensors track energy, water, and material flows. You see equipment performance and emissions instantly. You optimize resource use and reduce waste. Real-time monitoring helps you identify idle equipment and adjust energy use. You track water consumption and detect leaks quickly. Predictive maintenance keeps your machinery efficient and reduces downtime. Emissions tracking ensures you stay within limits and meet regulations. You use digital twins to simulate production and find ways to cut scrap and energy use.

Block Quote: Real-time monitoring empowers you to make proactive decisions, improve efficiency, and align your factory with sustainable production standards.

You gain:

You gain many advantages when you choose sustainable manufacturing. These benefits go beyond just helping the environment. You see lower costs, stronger business growth, and a better reputation. The table below shows how different sustainable practices lead to positive environmental impact:

| Sustainable Practice | Environmental Benefit |

|---|---|

| Energy Source Replacement | Reduces fossil fuel use and lowers emissions |

| Waste Audits and Recycling | Cuts landfill waste and improves resource efficiency |

| Use of Eco-Friendly Materials | Lowers pollution and carbon footprint |

| Energy-Efficient Equipment | Decreases energy use and environmental impact |

| Safer Work Environment | Supports a healthier workplace and environment |

You also notice these business benefits:

When you use digital tools like FineReport, you track energy use, waste, and emissions in real time. This helps you make smart decisions and reach your sustainability goals faster.

You may face several challenges as you move toward sustainable solutions. Here are some of the most common:

You can overcome many of these challenges by using digital platforms. FineReport helps you integrate data, monitor progress, and automate reporting. This makes it easier to manage resources and improve your environmental impact.

You see real results when you put sustainability into action. For example, Danfoss, a FanRuan client, increased labor productivity by 30% and reduced customer complaints by 57% after adopting digital dashboards and sustainable practices. Other companies like Patagonia and Interface have cut their environmental impact and grown their brands by using recycled materials and renewable energy.

| Company | Sustainable Manufacturing Practices | Outcomes & Benefits |

|---|---|---|

| Danfoss | Digital dashboards, energy tracking, lean production | 30% productivity boost, 57% fewer complaints |

| Patagonia | Organic cotton, recycling, renewable energy | Lower impact, sales growth, loyal customers |

| Interface | Recycled materials, closed-loop systems, carbon offsetting | Cost savings, better reputation |

You can achieve similar results by combining sustainable manufacturing with digital tools. This approach helps you reduce your environmental impact, improve efficiency, and build a future-ready business.

You can build a sustainable factory by focusing on energy efficiency, waste reduction, and responsible sourcing. Start with these steps:

When you embrace digital transformation, you future-proof your operations and create a culture of innovation. Explore more about sustainable production and digital solutions to lead your factory toward lasting success.

Click the banner below to try FineReport for free and empower your enterprise to transform data into productivity!

Top 10 ESG Software Solutions for Businesses in 2025

What is ESG reporting and why it matters for your business

Sustainable manufacturing explained and why it matters today

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

9 Best Supply Chain Tools for Smarter Management in 2026

Find the best supply chain tools for 2025 to boost efficiency, gain real-time insights, and achieve smarter management for your business.

Lewis

Dec 18, 2025

Top 10 Supply Chain Tracking Software for 2026

Compare the top supply chain tracking software for 2026 to boost visibility, automate workflows, and leverage AI analytics for smarter decisions.

Lewis

Dec 18, 2025

Top 10 Supply Chain Management Software for Small Businesses

See the top 10 supply chain management software comparison for small businesses in 2026. Compare features, pricing, and scalability to find your best fit.

Lewis

Dec 18, 2025