Manufacturing intelligence gives you the power to transform manufacturing in 2025. You use process intelligence, AI, and real-time data to boost intelligence, drive efficiency, and make smart, data-driven decisions. The global market for manufacturing intelligence solutions will reach $5.98 billion in 2025, reflecting strong growth.

| Year | Market Size (USD Billion) |

|---|---|

| 2024 | 5.44 |

| 2025 | 5.98 |

| 2034 | 13.92 |

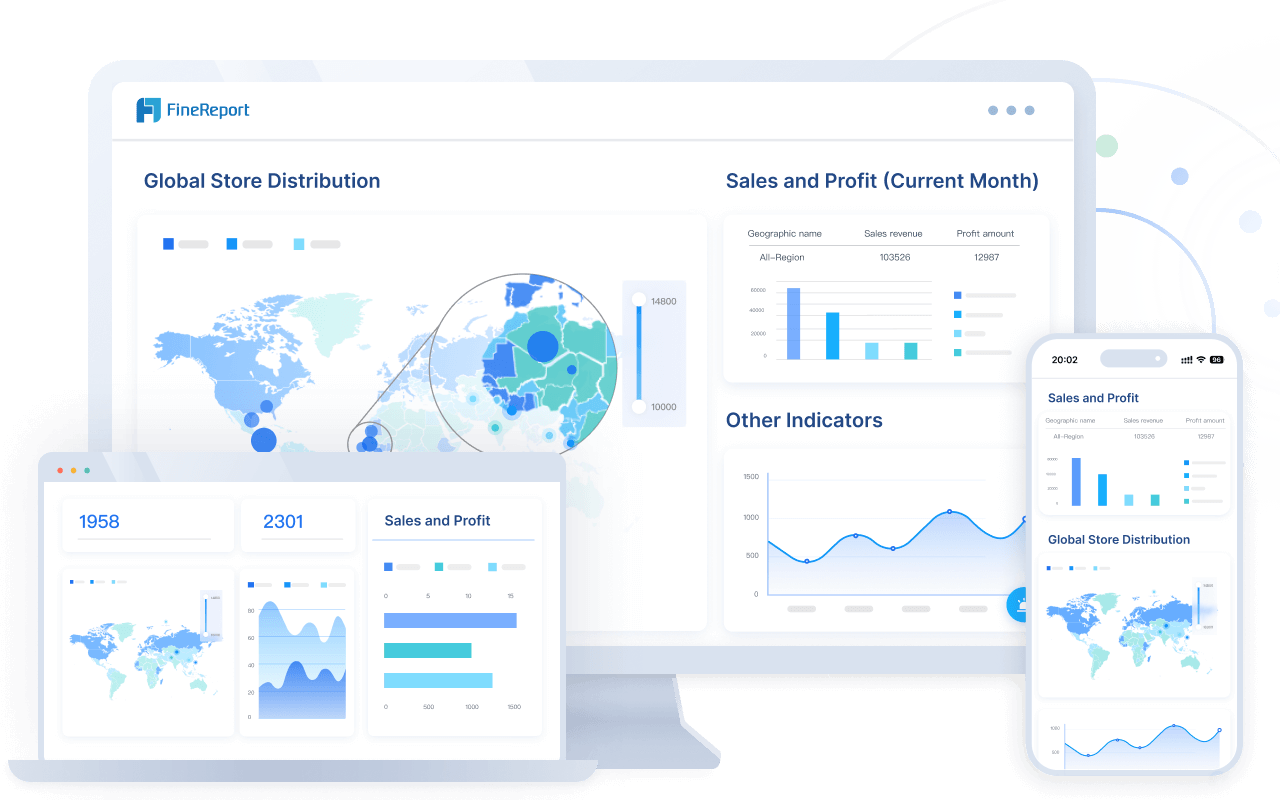

Over half of manufacturers now use AI and process intelligence to optimize production and gain a competitive edge. FanRuan, with FineReport and FineVis, helps you integrate intelligence into every step of your operations.

You live in a world where manufacturing changes fast. Manufacturing intelligence gives you the tools to keep up and stay ahead. It means using advanced technologies to make your factory smarter, more connected, and more efficient. You combine process intelligence, artificial intelligence, and real-time monitoring to create a system that learns and adapts.

In the Industry 4.0 era, manufacturing intelligence brings together the physical and digital worlds. You use cyber-physical systems to connect machines, people, and computers. This integration lets you control, monitor, and improve every process step. You see intelligence in action when your systems collect information, analyze it, and help you make better decisions.

Academic and industry experts describe manufacturing intelligence as the use of advanced information and communication technologies. You apply these tools to create adaptive and efficient manufacturing systems. You can design, control, and monitor every process with intelligence built in. This approach helps you respond quickly to changes and challenges.

Process intelligence is a key part of this transformation. You use it to understand how each process works, find bottlenecks, and improve performance. When you combine process intelligence with AI and big data, you unlock new insights and drive continuous improvement.

Tip: Manufacturing intelligence is not just about technology. It is about using process intelligence to make every part of your operation smarter and more responsive.

You build manufacturing intelligence on several core components. Each one plays a role in making your processes smarter and more efficient.

| Component Category | Key Elements and Description |

|---|---|

| Data Collection & Integration | IoT sensors, PLCs, and ERP systems gather and combine information from across your factory. |

| Process Optimization | You use analytics to schedule production, control quality, and improve each process step. |

| Advanced Data Analytics | Machine learning and real-time monitoring help you find patterns and solve problems quickly. |

| Predictive Maintenance | You monitor equipment conditions and predict failures before they happen, reducing downtime. |

| Visualization & Reporting | Dashboards and reports turn complex information into clear, actionable insights for everyone on your team. |

You rely on several technologies to power manufacturing intelligence in 2025:

You also need a strong process intelligence foundation. This means collecting information from sensors, machines, and people. You integrate this information into unified databases. You analyze it using descriptive, diagnostic, predictive, and prescriptive analytics. You then use dashboards and manufacturing analytics software to visualize the results. Finally, you act on these insights to improve efficiency, cut costs, and boost profitability.

Note: When you use process intelligence and these technologies together, you create a manufacturing system that can adapt, learn, and grow with your business.

You gain a clear edge when you use manufacturing intelligence in your operations. This edge comes from real, measurable benefits that help you stay ahead of your competitors. Let’s look at how intelligence transforms your business:

| Competitive Advantage Area | Measurable Benefits and Evidence |

|---|---|

| AI-driven Quality Control | 50% of manufacturers plan AI/ML for quality assurance; improves product consistency, regulatory compliance, and operational efficiency; generates real-time data streams for strategic decision-making. |

| Cybersecurity | 42% plan AI/ML deployment for cybersecurity; manufacturing sector faces 21% of ransomware attacks; strong cybersecurity skills improve talent acquisition and protect IP and operations. |

| Workforce Transformation | 48% expect workforce repurposing or expansion; 83% prioritize analytical and teamwork skills; 47% rate AI application skills as extremely important, supporting strategic insights from AI data. |

| Supply Chain Resilience | Use of predictive analytics and real-time visibility to anticipate disruptions; Cisco’s multi-tiered supply chain model reduces bottlenecks and costs from disruptions. |

| Sustainability | Transition from compliance to competitive edge; examples include Unilever’s reduction in virgin plastic use and investments in renewable energy and water conservation, reducing costs and enhancing brand. |

| Digital Transformation | Digitized product catalogs improve buyer engagement and reduce costs; 82%+ B2B buyers use digital commerce; AI tools automate quality control and optimize production in real time. |

You see these advantages in action every day:

Manufacturing intelligence also helps you optimize operations. For example, intelligent sensor technology like IO-Link lets you adjust and monitor sensors in real time. You reduce downtime and maintenance costs. You improve throughput and keep your factory running smoothly.

Tip: When you invest in intelligence, you build a foundation for continuous improvement. You make your business more agile and ready for future challenges.

You play a key role in building a sustainable future when you adopt manufacturing intelligence. This approach helps you protect the environment, save resources, and meet new market demands.

Sustainable manufacturing uses intelligence to minimize negative impacts. You reduce energy use, cut waste, and support recycling. Companies that focus on sustainability often see higher profits and better reputations. For example, reducing energy consumption by 15% can save over $1.2 million each year. You also improve compliance with environmental regulations through automated data collection and reporting.

Here are some ways intelligence supports sustainability:

Industry 4.0 technologies, such as AI, IoT, and Big Data, help you understand and manage your production environment. You create flexible systems that adapt to changing market needs. You also support circular economy practices, which keep resources in use longer and reduce environmental impact.

Looking ahead, you will see several trends shaping manufacturing intelligence:

Note: You prepare for the future by investing in AI quality control, compliance tools, cybersecurity, and training. These steps help you stay competitive and resilient in a fast-changing world.

You see ai in manufacturing changing how factories work every day. AI and automation help you solve problems faster and make your processes more efficient. Robots handle repetitive or dangerous tasks, keeping your team safe and boosting productivity. AI systems analyze data from sensors and machines, then suggest ways to improve quality and reduce waste.

Here is how ai in manufacturing is used to optimize your operations:

| AI Application Area | Description of AI Use in Manufacturing |

|---|---|

| Material Consumption | AI algorithms suggest the best cutting patterns, monitor production, and recommend actions to reduce losses. Machine learning adjusts settings to maximize quality. |

| Predictive Maintenance | AI checks sensor data for signs of trouble, predicts failures, and schedules repairs to avoid downtime. Alerts help you fix issues before they stop production. |

| Quality Control | AI-powered inspection systems spot tiny defects, sort parts, and work with robots to remove faulty items. AI finds defect sources and suggests fixes. |

| Production Planning | AI maps your processes and updates schedules based on demand and resources. It reallocates resources and keeps production running smoothly. |

You use automation technologies like robotics, IoT, 3D printing, and augmented reality to create new automation opportunities. Robotics automate tasks with high accuracy and speed. IoT connects machines for real-time communication. 3D printing lets you make complex parts quickly. Augmented reality gives your workers instant information, helping them avoid mistakes.

AI also helps you address labor shortages. It analyzes assembly steps and improves factory layouts. Generative AI automates robot programming, saving time. AI supports your team with just-in-time training, making everyone more capable.

Tip: AI and automation work together to make your factory smarter. You get better quality, faster production, and safer workplaces.

You rely on real-time data and analytics to make smart decisions in manufacturing. AI in manufacturing uses live dashboards to show you what is happening right now. You see machine performance, supply chain status, and quality metrics instantly. This helps you spot problems early and fix them before they grow.

Here is a table showing how real-time data analytics improves decision-making:

| Aspect of Real-Time Data Analytics | How It Improves Decision-Making in Manufacturing |

|---|---|

| Real-Time Operational Monitoring | IoT sensors give you instant updates on machines and logistics, so you can adjust quickly. |

| Predictive Maintenance | You predict equipment failures and plan repairs, reducing downtime and costs. |

| Supply Chain Optimization | You track inventory and demand, making your supply chain more reliable. |

| Product Quality Enhancement | Early defect detection lets you improve standards and reduce waste. |

| Data Integration and Overcoming Silos | Centralized data warehouses give you a complete view, supporting better decisions. |

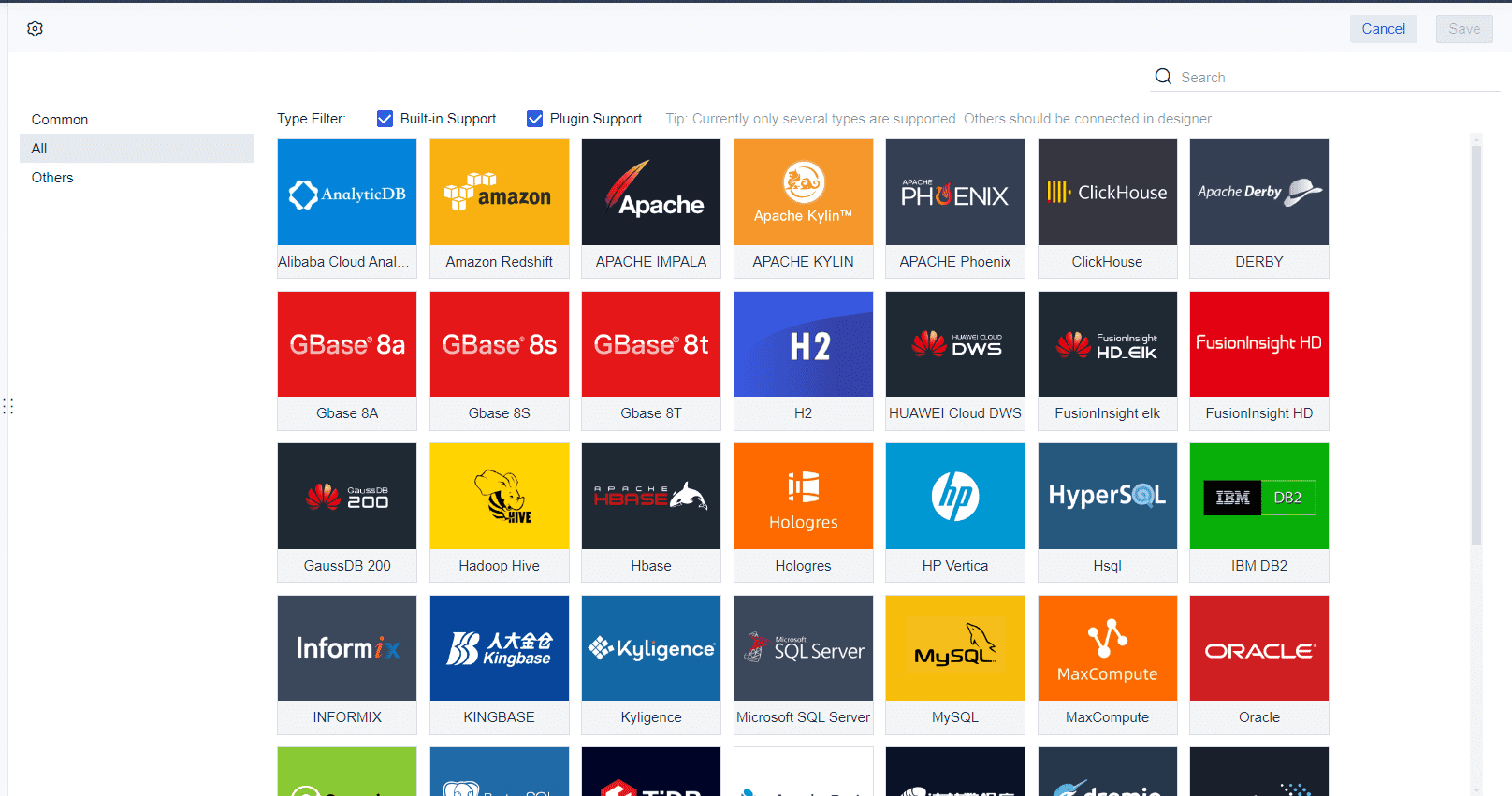

You use analytics tools like FineReport, Microsoft Power BI, Siemens MindSphere, IBM Watson IoT, and SAS Analytics Solutions. These platforms help you visualize data, monitor production, and optimize your processes. AI models detect patterns and anomalies, turning your data into actionable insights.

Live dashboards let you act fast. Predictive analytics help you plan ahead. You improve financial decisions by tracking expenses and cash flow in real time. Data-driven choices support growth and efficiency at every level.

Note: Real-time data and analytics turn your manufacturing from reactive to proactive. You stay ahead of problems and keep your operations running smoothly.

You face many challenges when you try to connect different systems and data sources in a smart factory. To succeed, you need to follow best practices that make integration smooth and effective:

You also need to connect devices and software using protocols like MQTT for real-time messaging. Integrating PLCs with MES and SCADA systems helps you automate and unify your process. Cloud computing and APIs allow you to share data across platforms, creating a unified ecosystem. By following these steps, you build a foundation for real-time process intelligence, monitoring, and control.

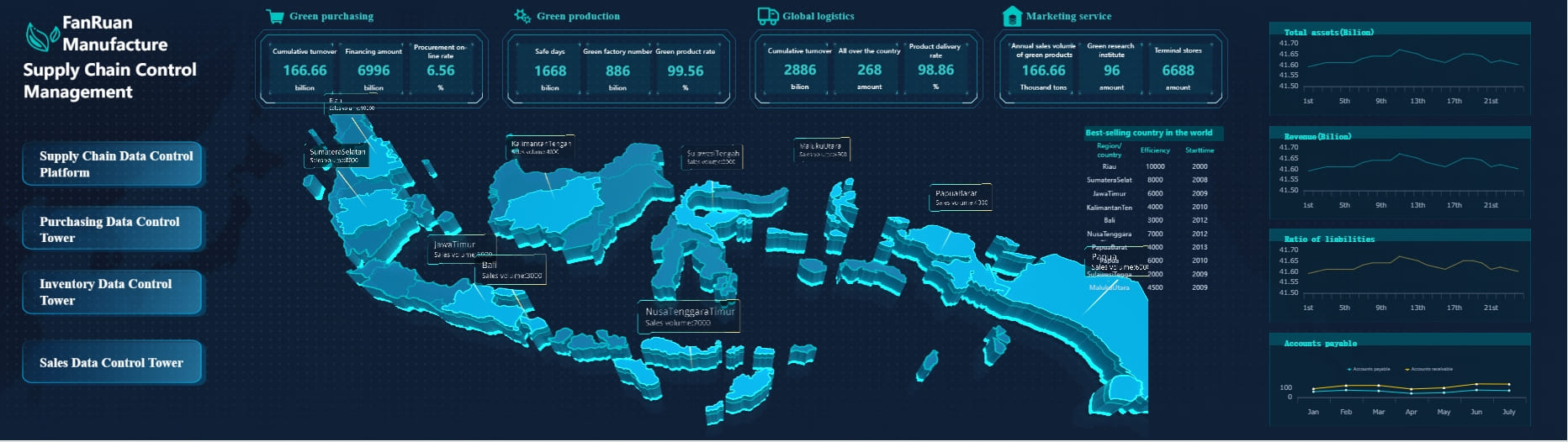

You can use FineReport to bring together data from suppliers, warehouses, and logistics partners. The platform supports process intelligence by letting you track every step, from order to delivery. You get real-time dashboards that show inventory levels, shipment status, and delivery timelines. This helps you spot delays and make quick decisions to keep your supply chain moving.

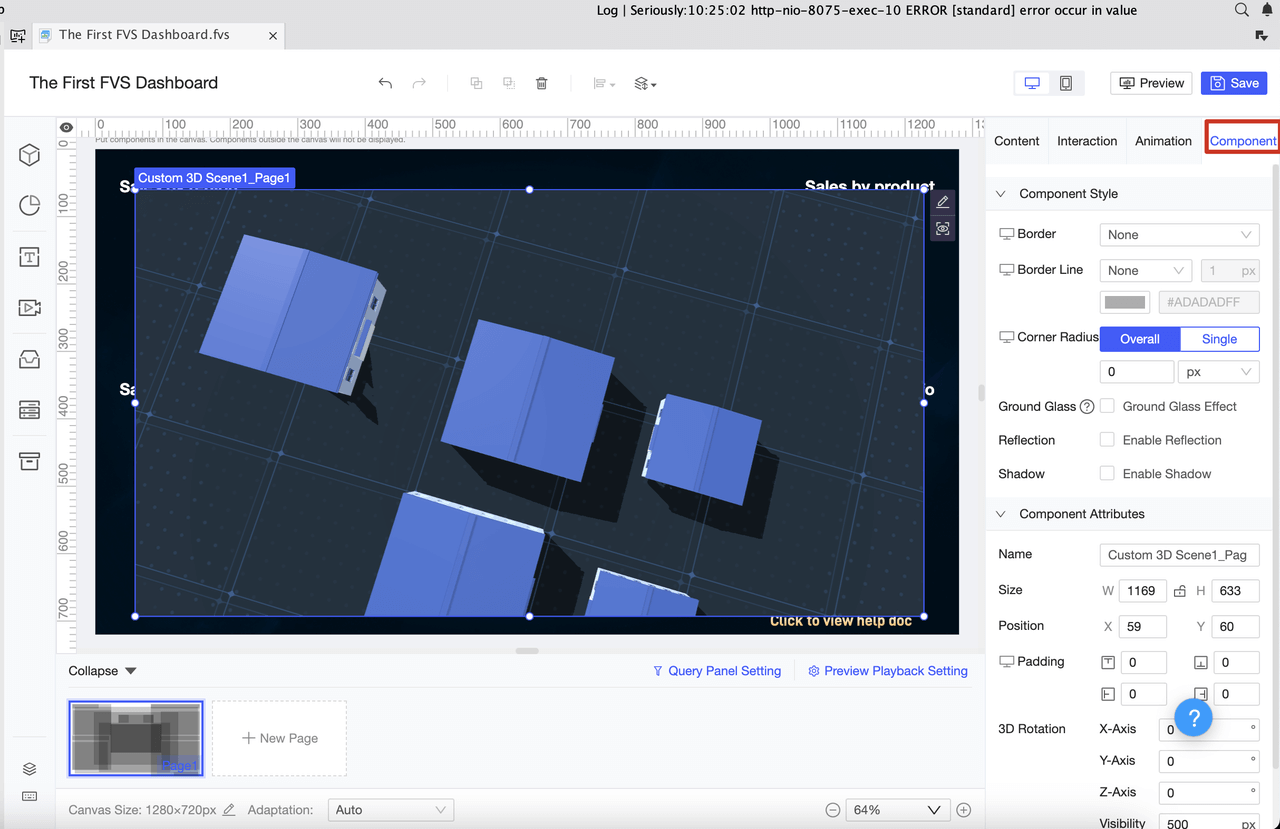

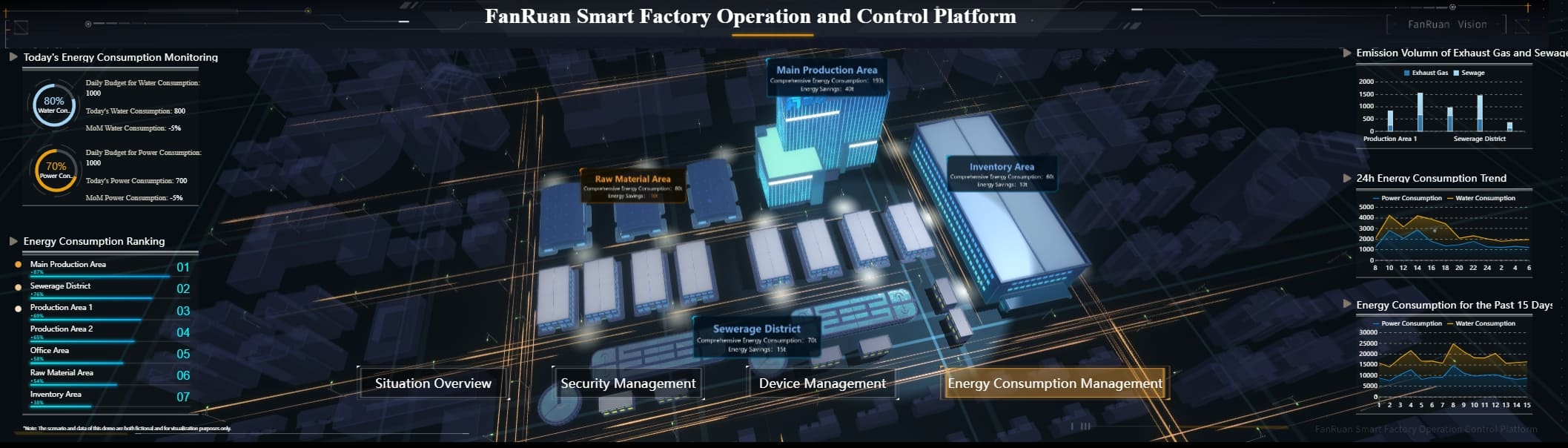

FineVis gives you powerful visualization tools for your smart factory. You can create 3D dashboards that show live production monitoring, equipment status, and process flows. The drag-and-drop interface lets you build custom views without coding. You see bottlenecks, track process performance, and use process intelligence to optimize operations. Touch-screen controls and mobile access make it easy to manage your factory from anywhere.

You use FineReport to collect and analyze data from every process in your factory. The platform supports process intelligence by integrating data from machines, sensors, and people. You can monitor production rates, quality, and equipment efficiency. Scheduled reporting and automated alerts help you respond quickly to issues. Real-world examples show that manufacturers using these tools have improved delivery speed, reduced downtime, and increased profitability.

Tip: When you combine process intelligence, real-time monitoring, and advanced visualization, you gain full control over your smart factory and achieve better delivery outcomes.

When you start implementing process intelligence in your factory, you face several integration challenges. You need to identify user roles and their specific data needs. Each person in your team uses data differently to improve operations. You must define and standardize KPIs so everyone measures success the same way. You also need to find all relevant data sources across your systems for a complete analysis. Picking the right data presentation interfaces helps each user get actionable insights quickly.

Common obstacles include data silos and fragmented information. Different systems may use different data formats, making it hard to combine everything. Middleware solutions help bridge old and new systems, allowing real-time data sharing. You can reduce risks by testing and validating each phase of integration. This approach improves data reliability and supports smooth delivery of information.

As your manufacturing intelligence platform grows, you must keep it secure and scalable. More connections mean more entry points for cyber threats. You need to protect your systems from attacks like data poisoning or model inversion, which can leak sensitive information. A secure-by-design approach helps you build defenses from the start. Use encryption, access controls, and continuous monitoring to keep your data safe.

To ensure scalability, standardize best practices and workflows across all sites. Real-time visibility and seamless data flow support centralized decision-making. Modular and flexible systems let you adapt to different manufacturing types. Cloud-native architectures and prebuilt templates speed up deployment and prevent bottlenecks.

You can follow clear steps to adopt manufacturing intelligence using FanRuan’s tools. Start with a PDCA (Plan-Do-Check-Act) cycle. Plan by setting goals and analyzing your current process. Do by implementing improvements and documenting results. Check by comparing outcomes with your objectives. Act by standardizing successful practices and preparing for the next cycle. This method supports continuous improvement tools and spiral growth.

Change management and training are key. Leadership support helps align your goals. Open communication addresses employee concerns. FanRuan’s user-friendly dashboards and customizable interfaces make it easy for everyone to interact with data. Training programs balance theory and practice, using workshops and online modules. Ongoing upskilling ensures your team stays current as systems evolve.

Tip: When you use FanRuan’s FineReport and FineVis, you simplify integration, automate reporting, and empower your team with real-time, actionable insights for better process management.

You see manufacturing intelligence changing how you work in 2025. AI and process intelligence help you reduce downtime, optimize inventory, and improve quality. Tools like FanRuan, FineReport, and FineVis give you real-time insights and automation.

| Future Trend | What You Can Expect |

|---|---|

| Digital twins | Simulate and optimize your factory |

| AI-driven automation | Predict, adapt, and improve results |

| Sustainable manufacturing | Use less energy and recycle more |

You prepare for a future where smart factories run autonomously, supported by skilled teams and advanced technology.

Click the banner below to try FineReport for free and empower your enterprise to transform data into productivity!

What is Manufacturing Operations Management and Why It Matters

Best Manufacturing Management Software for Modern Factories

How to Create a Manufacturing Dashboard (Step-by-Step Guide)

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

9 Best Supply Chain Tools for Smarter Management in 2026

Find the best supply chain tools for 2025 to boost efficiency, gain real-time insights, and achieve smarter management for your business.

Lewis

Dec 18, 2025

Top 10 Supply Chain Tracking Software for 2026

Compare the top supply chain tracking software for 2026 to boost visibility, automate workflows, and leverage AI analytics for smarter decisions.

Lewis

Dec 18, 2025

Top 10 Supply Chain Management Software for Small Businesses

See the top 10 supply chain management software comparison for small businesses in 2026. Compare features, pricing, and scalability to find your best fit.

Lewis

Dec 18, 2025