A manufacturing management system is a software-based solution that helps you control, monitor, and optimize manufacturing operations. You use it to connect machines, people, and processes, creating a unified flow of real-time data.

You benefit from digital transformation and data-driven decision-making in several ways:

- Real-time integration with IoT, AI, and robotics improves manufacturing efficiency and quality.

- Data analytics and automation give you actionable insights and predictive maintenance.

- Real-time monitoring helps you react quickly to market changes and disruptions.

Solutions like FanRuan and FineReport enable you to harness real-time data, boost efficiency, and drive smarter manufacturing decisions.

Manufacturing Management System Overview

What is Manufacturing Management System

A manufacturing management system is a software-based solution that helps you control, monitor, and optimize every aspect of your manufacturing operations. According to industry standards like MESA and VDI Guideline 5600, this system acts as a dynamic information hub. It connects your enterprise-level planning tools with the shop floor, bridging the gap between business goals and actual production. You use it to track, document, and improve your production process in real-time.

The main functions of a manufacturing management system cover all areas of production management and manufacturing operations management. You can see how each function supports your daily work in the table below:

| Primary Function | Description |

|---|---|

| Design Assessment | Estimate system performance and allocate resources using models of your manufacturing operations. |

| Capacity Requirements Planning | Analyze if you can meet demand on time by checking resource needs before scheduling. |

| Scheduling | Assign resources and set start and finish times for jobs based on your production process plans. |

| Schedule Management | Adjust schedules using real-time operational status and critical issues to keep your shop floor running smoothly. |

| Schedule Execution and Dispatching | Put the schedule into action on the shop floor, ensuring disciplined execution and feedback for improvement. |

| Status Presentations and Statistics | Display operational data and statistics to support decision-making and simulate improvements in capacity and operations. |

You rely on a manufacturing management system to bring together all your processes, from design and planning to execution and reporting. This system helps you maintain quality, reduce costs, and ensure that your production process meets both business and regulatory requirements. For example, in industries like pharmaceuticals, automotive, and food and beverage, you must follow strict standards such as ISO 9001, GMP, and HACCP. The system helps you document, monitor, and prove compliance with these rules.

How It Works

You use a manufacturing management system to automate and integrate your manufacturing operations. The system connects machines, people, and processes, creating a seamless flow of real-time data. Here is how it works in practice:

- Standardized automation across your plants gives you a unified view of all operations. You can manage multiple sites from one platform and make decisions based on consistent, accurate data.

- Automation tools like CNC machines, PLCs, and robotic systems carry out specific tasks. These tools receive instructions from the system and send back real-time updates on machine status, downtime, and maintenance needs.

- Machine monitoring software collects and organizes data into actionable reports. You can track equipment effectiveness, schedule production, and predict when maintenance is needed.

- Integration of software and hardware allows you to collect, analyze, and act on data continuously. This forms the backbone of your manufacturing operations management.

You benefit from this integration in several ways:

- You improve efficiency and accuracy by applying the same automation processes across all locations.

- You reduce costs by minimizing custom solutions and lowering training and maintenance expenses.

- You maintain high-quality standards and ensure reliable product quality.

Modern manufacturing management systems also support sustainability and environmental goals. You can use lean manufacturing practices to reduce waste and optimize resource use. The system helps you track key sustainability metrics like energy consumption and waste generation. You can also integrate renewable energy sources and use simulation software to optimize your production process for lower environmental impact.

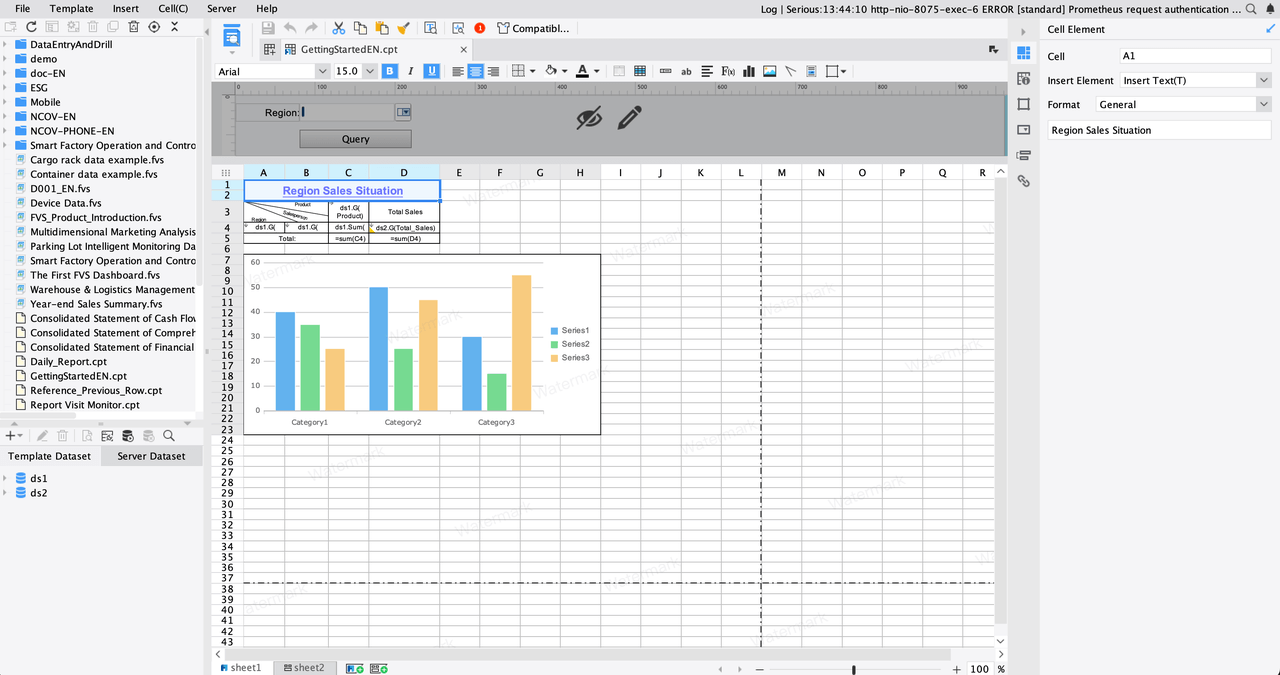

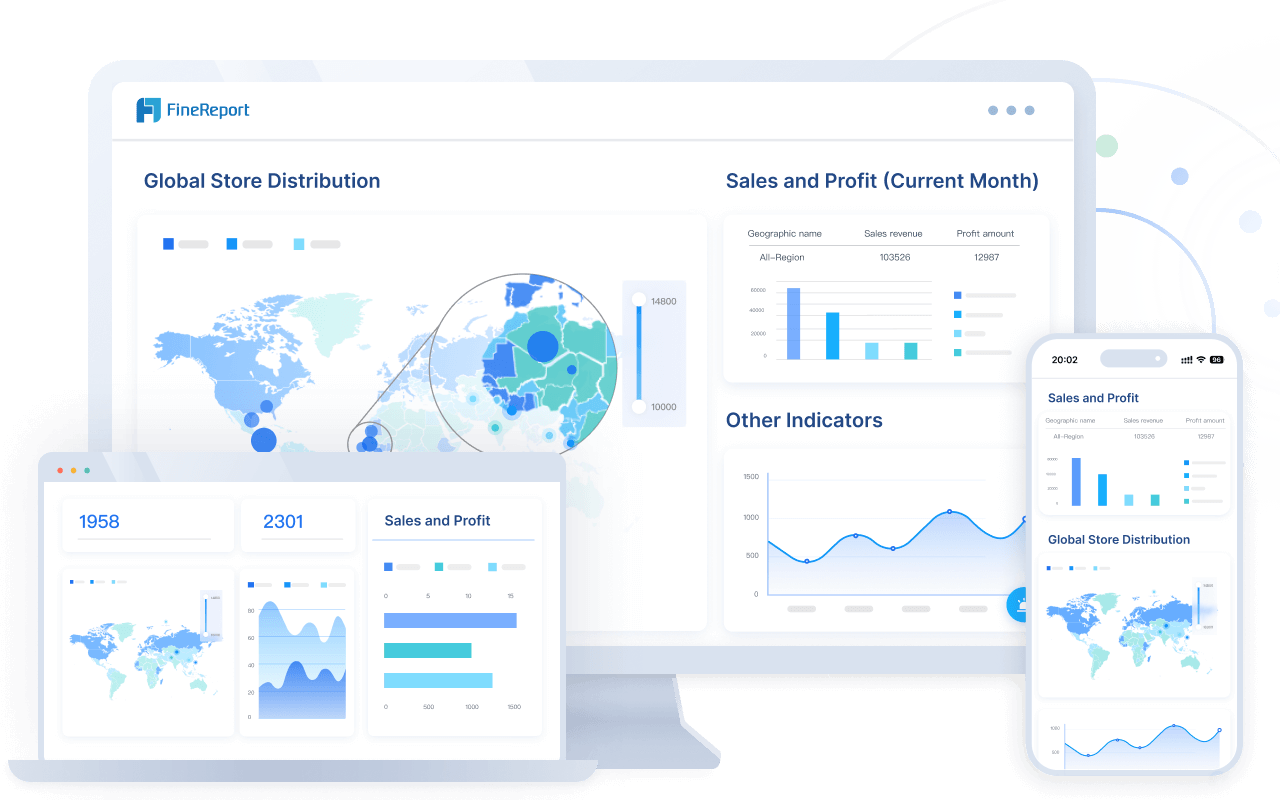

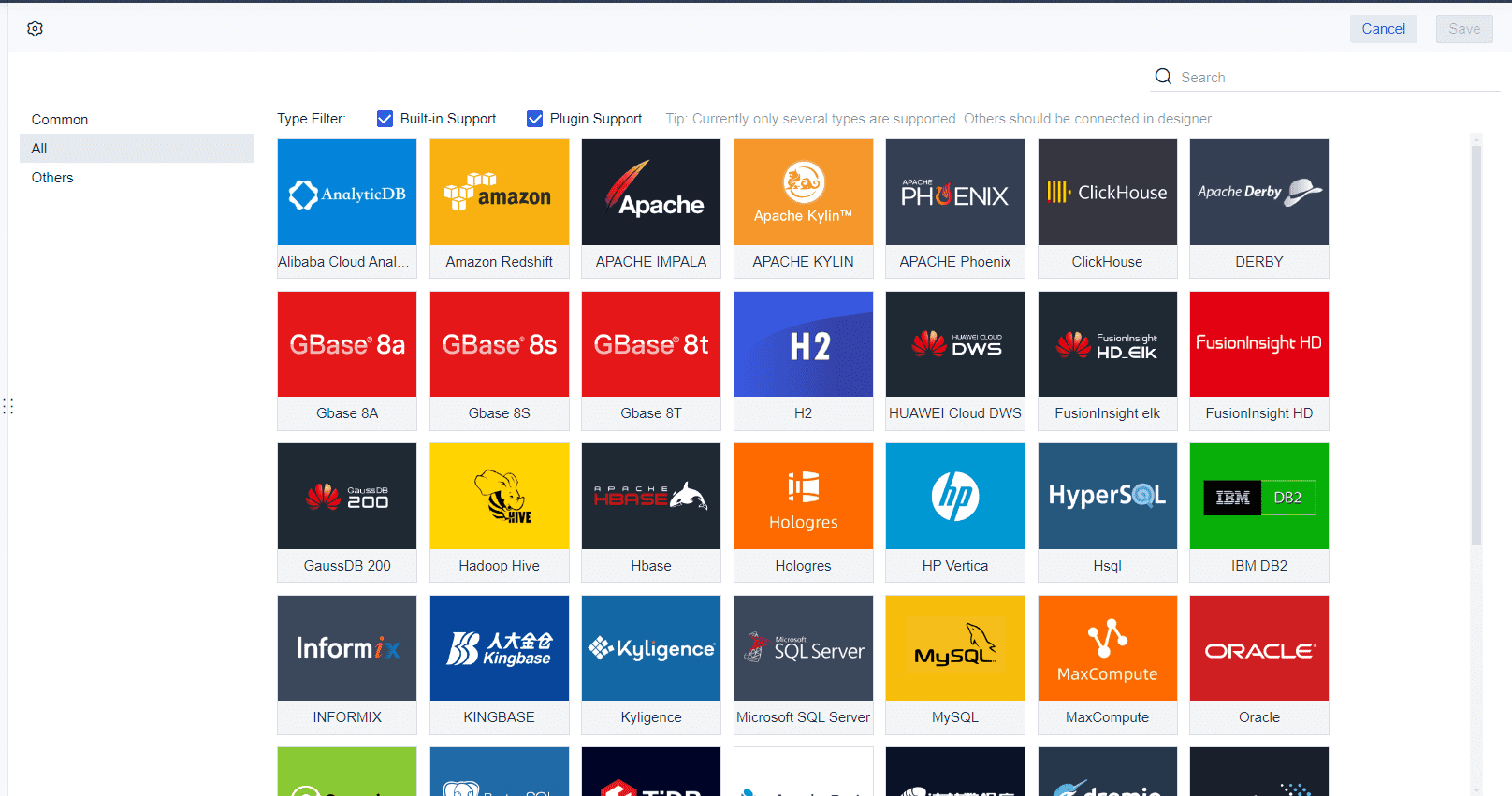

Digital platforms like FanRuan and FineReport play a key role in this ecosystem. You use FineReport to create dynamic reports and dashboards that visualize your real-time data. The platform connects to all your data sources, from production and supply to sales and finance. You can generate complex reports, set up scheduled tasks, and build management cockpits that give you a clear view of your entire operation. This level of integration and visualization supports better decision-making and helps you achieve lean, efficient, and intelligent manufacturing operations management.

Compared to traditional management approaches, a manufacturing management system gives you greater scalability and adaptability. You can scale up quickly by adding new modules or integrating new plants without major disruptions. Real-time monitoring and predictive analytics help you anticipate challenges and optimize your production process. You stay agile and competitive in a fast-changing market.

Tip: By using a manufacturing management system, you not only streamline your production management but also ensure compliance, support sustainability, and gain the flexibility to grow and adapt your business.

Key Components of Manufacturing Management System

Modern manufacturing relies on several core systems that work together to streamline your operations and drive efficiency. Understanding these components helps you see how each one supports your manufacturing processes and how you can use tools like FineReport to bring everything together for better decision-making.

Manufacturing Execution System (MES)

A manufacturing execution system sits at the heart of your shop floor. You use it to manage, monitor, and control your manufacturing processes in real time. MES bridges the gap between your business planning systems and the actual production line, ensuring that your operations run smoothly from top floor to shop floor.

| Key Features / Benefits of MES | Description |

|---|---|

| Visibility | Provides real-time, accurate, and accessible data from the shop floor to improve decision-making. |

| Error-proofing production | Helps prevent errors during manufacturing processes to ensure quality. |

| Agility | Enables quick response to changes in production or market demands. |

| Inventory accuracy | Improves tracking and management of inventory levels. |

| Enhanced traceability and compliance | Supports tracking of parts, materials, and processes to meet regulatory requirements. |

| Better communication throughout the business | Facilitates information flow between production and business systems like ERP. |

| Driving continuous improvement | Uses data analytics to identify inefficiencies and improve processes. |

| Faster new product introduction | Speeds up the launch of new products by streamlining production workflows. |

| Efficiencies and cost-savings | Reduces waste, downtime, and operational costs through optimized execution. |

| Top floor to shop floor integration | Bridges planning/logistics systems with plant floor operations for seamless coordination. |

You benefit from MES by establishing production plans, maintaining schedule adherence, and enforcing consistent processes. MES gives you real-time progress visibility, helps you meet quality control standards, and creates a rich data set for continuous improvement. When you use a cloud-based MES, you gain even more flexibility and scalability, allowing you to manage multiple sites and access data from anywhere.

FineReport supports MES by integrating data from your shop floor and visualizing it through dynamic dashboards. You can track production scheduling, monitor key metrics, and generate reports that help you identify bottlenecks and optimize your manufacturing execution systems.

Note: MES acts as a holistic solution, connecting your ERP and automation systems. With FineReport, you can easily bridge these systems and gain actionable insights for smarter manufacturing.

Material Requirements Planning (MRP)

Material Requirements Planning is your tool for inventory optimization. You use MRP to analyze sales forecasts, customer orders, inventory levels, and lead times. This analysis tells you exactly what materials you need, how much you need, and when you need them. MRP ensures that materials arrive just in time for production, which prevents both stockouts and excess inventory.

MRP integrates production scheduling with inventory management and supply chain processes. It automates procurement and scheduling, helping you keep inventory levels low while still meeting production demands. Companies that use MRP often see lower inventory costs, shorter lead times, and overall cost savings. Modern MRP systems use AI and cloud computing to give you real-time visibility and predictive analytics, making your inventory management systems even more effective.

FineReport connects with your MRP system to provide real-time reporting and analysis. You can visualize material flows, monitor inventory levels, and automate alerts for shortages or excesses. This integration helps you maintain efficient manufacturing processes and avoid costly disruptions.

Tip: By using FineReport with your MRP, you can automate material requirements updates and supply orders, keeping your production on track and your costs under control.

Enterprise Resource Planning (ERP)

Enterprise Resource Planning systems give you a 360-degree view of your entire manufacturing business. You use ERP to manage materials, resources, and systems, improving operational efficiency and supporting better decision-making. ERP streamlines core processes like inventory management, supply chain management, production planning, and financial management.

- Inventory management: Track raw materials to finished goods, optimize stock levels, and streamline warehouse operations.

- Production planning: Schedule production processes, manage resources, and align output with market demand.

- Quality control and compliance: Monitor quality metrics, manage defects, and ensure regulatory compliance.

- Financial management: Centralize financial data to track costs, manage cash flow, and support informed decisions.

- Supply chain management: Optimize the flow of goods and services, improve supplier relationships, and ensure timely deliveries.

- Human resources: Integrate employee data management, payroll, and recruitment.

- Customer relationship management: Track customer interactions to improve satisfaction and drive sales.

- Equipment performance tracking: Monitor machinery health to optimize maintenance and reduce downtime.

- Purchasing: Streamline procurement, supplier selection, and negotiation.

- Artificial intelligence integration: Enhance production optimization, demand prediction, and decision-making.

- Cloud connectivity: Access your ERP anytime, anywhere, with scalability and flexibility.

You rely on ERP to reduce inventory and labor costs, increase productivity, and ensure compliance with regulations. ERP systems also support better resource utilization and scheduling, enabling you to make data-driven decisions that boost performance and customer satisfaction.

FineReport enhances your ERP by integrating data from multiple sources and presenting it in clear, actionable dashboards. You can create custom reports, monitor KPIs, and automate scheduled reporting, making it easier to manage your manufacturing operations and respond quickly to changes.

Computerized Maintenance Management System (CMMS)

A Computerized Maintenance Management System helps you keep your equipment running reliably. You use CMMS to track assets, schedule maintenance, and manage work orders. Real-time asset tracking and monitoring give you detailed records of asset performance and maintenance history, allowing you to resolve issues proactively and improve equipment reliability.

- Real-time asset tracking and monitoring

- Automated maintenance schedules and reminders

- Inventory management for spare parts and materials

- Integration with IoT sensors for predictive maintenance

- Work order management for efficient task assignment and tracking

- Consolidation of maintenance data for better communication and workflow automation

CMMS enables you to shift from reactive to proactive maintenance strategies. Industry data shows that using CMMS can increase maintenance productivity by over 28% and reduce downtime by more than 20%. Technicians can report asset failures on-site using smartphones, which shortens equipment downtime and improves workflow continuity.

FineReport integrates with your CMMS to provide real-time dashboards and analytics. You can monitor maintenance schedules, track equipment health, and generate reports that help you optimize maintenance strategies and reduce unplanned downtime.

Note: By consolidating maintenance data into a single platform, you improve communication, automate workflows, and allocate resources more effectively.

How FineReport Brings It All Together

You can use FineReport as a central reporting and visualization platform across all these systems. FineReport connects to MES, MRP, ERP, and CMMS, allowing you to:

- Integrate data from different sources for a unified view of your manufacturing operations.

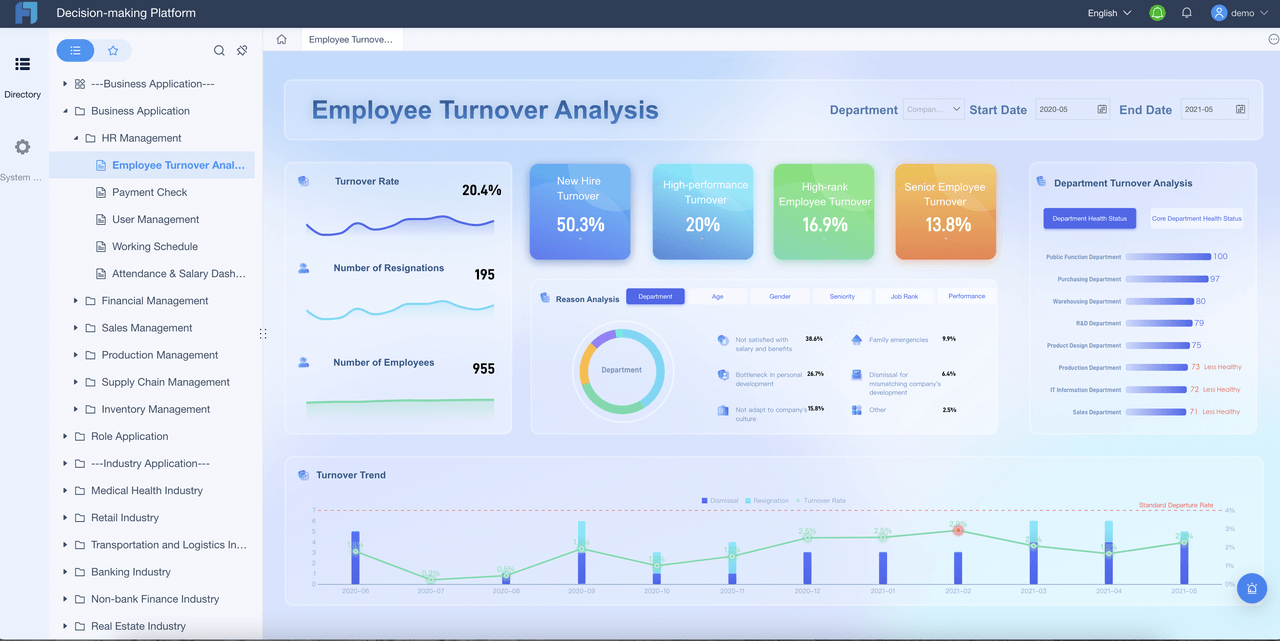

- Create dynamic dashboards that display real-time metrics from production scheduling to quality control.

- Automate reporting and alerts to keep your team informed and proactive.

- Support cloud-based MES and other cloud solutions for flexible, scalable manufacturing management.

With FineReport, you gain the power to turn complex manufacturing data into clear, actionable insights. This helps you optimize processes, improve quality, and drive continuous improvement across your entire manufacturing environment.

Integration in Manufacturing Management System

Data Flow and Connectivity

You need seamless data flow to monitor and control production processes across your entire manufacturing operation. Modern manufacturing management systems connect platforms like ERP, MES, QMS, and SCM. This integration lets you share real-time data between departments, giving you a complete view of your processes.

You often face challenges when you try to connect different systems. Some common issues include:

- Legacy systems make integration difficult because they do not work well with new applications.

- Data silos form when information is scattered across departments, making it hard to collaborate.

- Employees may resist changes, especially if they are used to old ways of sharing data.

- As your manufacturing grows, the amount and complexity of data increase, which can overwhelm older systems.

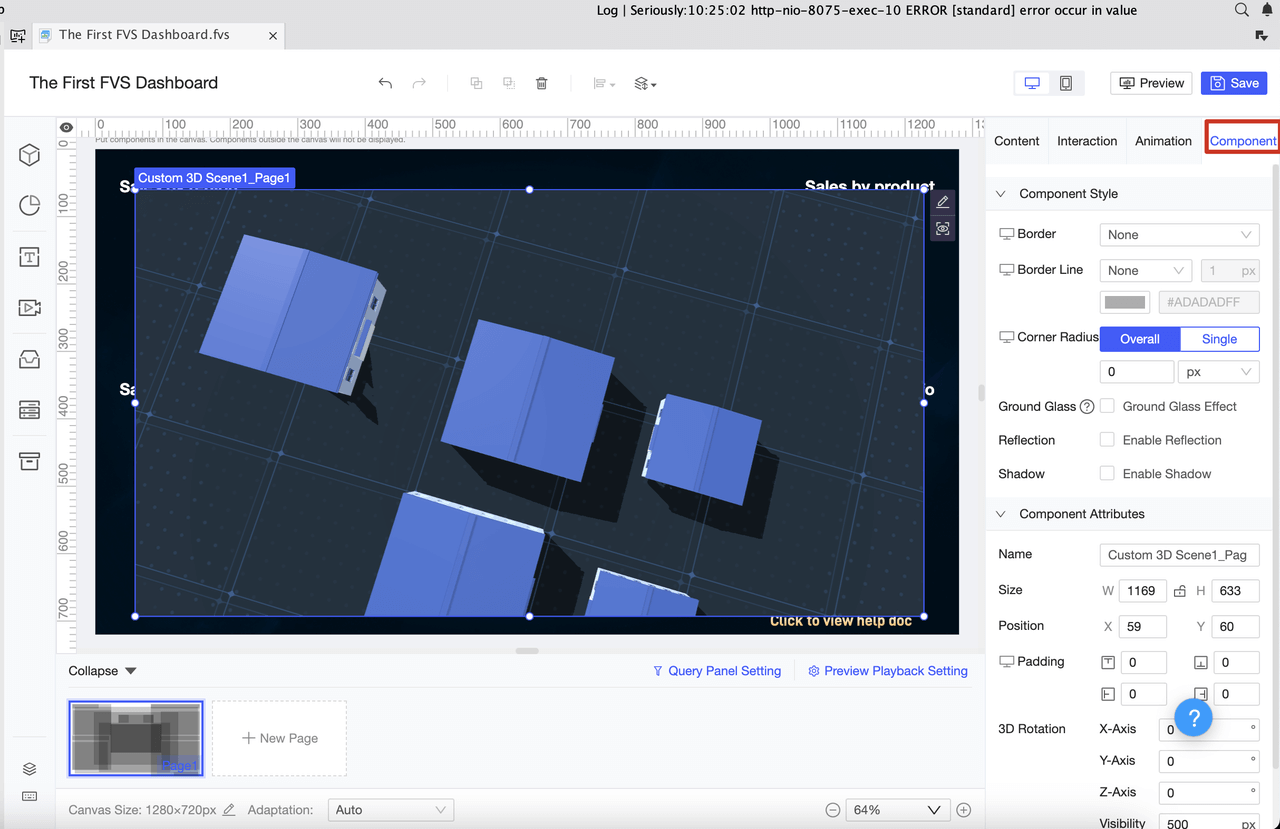

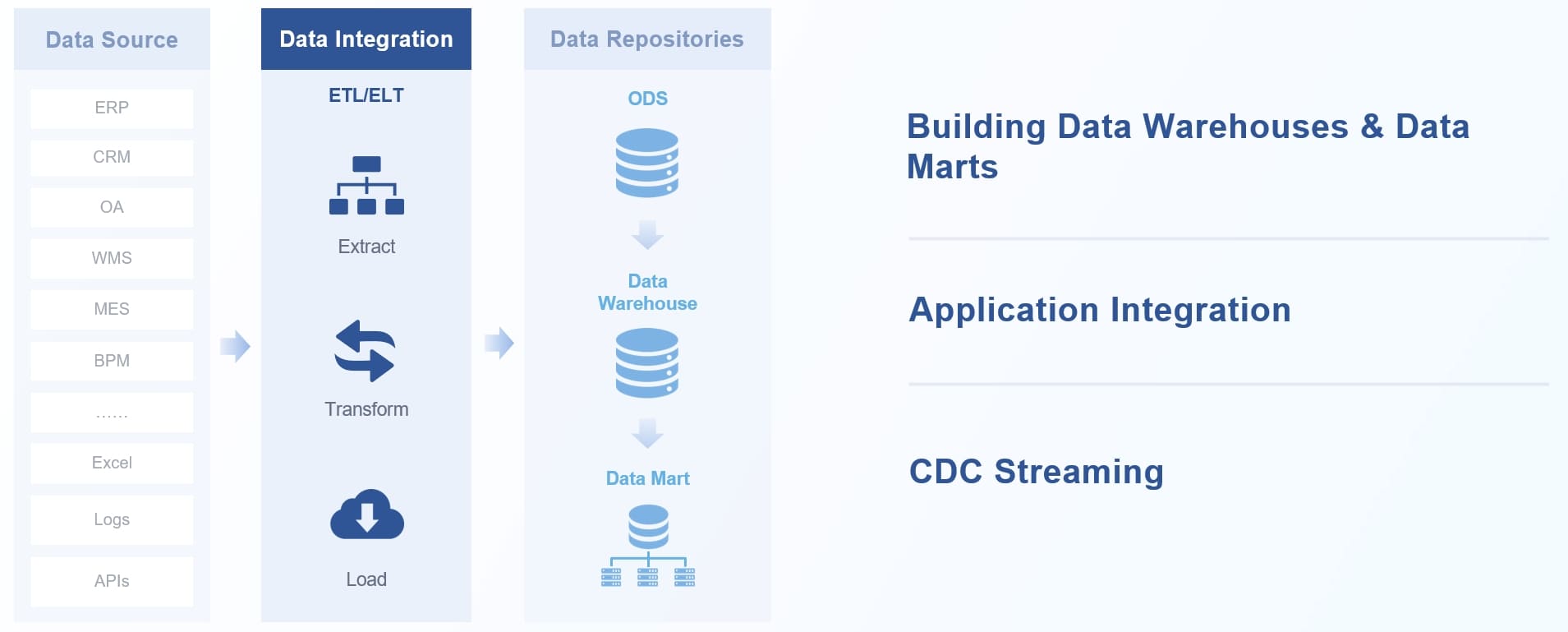

To solve these problems, you can use advanced data integration tools. FineReport and FanRuan's FineDataLink help you connect over 100 data sources. FineDataLink synchronizes production data collection in real time, supports ETL/ELT, and offers easy API development. These tools break down silos and automate data flow, so you can focus on supply chain optimization and better decision-making.

MES integration with ERP, QMS, and SCM creates seamless connections. This setup enables real-time data exchange, improves collaboration, and streamlines production scheduling, inventory tracking, and quality control. You gain real-time visibility and control over your manufacturing processes.

Real-Time Monitoring

Real-time monitoring is essential if you want to monitor and control production processes effectively. When you track data instantly, you spot problems, bottlenecks, or opportunities for improvement right away. Here is how real-time monitoring supports your manufacturing:

- You get up-to-date, accurate data for informed decisions.

- You can respond quickly to incidents, reducing downtime.

- You track KPIs and identify inefficiencies in your processes.

- You maintain high quality by detecting defects early.

- You schedule maintenance before breakdowns happen.

With FineReport dashboards, you visualize real-time data from all your systems. This helps you benchmark performance, optimize processes, and deliver high-quality products on time. Real-time monitoring also supports proactive maintenance and better workflow management, making your manufacturing more agile and competitive.

Benefits of Manufacturing Management System

Efficiency and Productivity

You gain significant efficiency and productivity improvements when you use a manufacturing management system. These systems automate routine tasks, streamline your production management, and help you monitor every step of the production process. Real-time data lets you spot issues quickly and adjust your operations for maximum output. The table below shows measurable improvements many manufacturers report after adopting these systems:

| Improvement Area | Measurable Improvement |

|---|---|

| Scrap Cost Reduction | 15-25% decrease |

| Rework Requirements | 20-35% decrease |

| Employee Absenteeism | 39% reduction |

| Production Efficiency | Increased through real-time monitoring and automated scheduling |

| Operational Costs | Reduced due to optimized resource usage and waste reduction |

| Quality Control | Enhanced, leading to less waste and defects |

| Key Performance Indicators | OEE, FPY, and manufacturing cost per unit quantify gains |

With FineReport, you can track production efficiency in real time. You see where delays happen and take action to keep your production process running smoothly. FanRuan solutions help you optimize manufacturing processes by connecting data from different departments, so you always have the information you need to make fast decisions.

Quality and Visibility

You improve quality control and gain better visibility into your operations with a manufacturing management system. Real-time monitoring lets you catch quality issues early in the production process, which reduces waste and boosts customer satisfaction. You can track supplier performance and spot bottlenecks before they slow down your production management.

Manufacturing Operations Management systems give you a single view of all your processes. You break down data silos and make decisions based on accurate, up-to-date information. FineReport dashboards let you visualize quality metrics and production efficiency, so you can focus on continuous improvement. When you use MES, you connect your ERP system with the shop floor, making it easier to manage resources and maintain high standards for quality control.

Cost Savings

You save money by reducing waste, lowering rework, and improving resource allocation. Automated scheduling and real-time data help you use materials and labor more efficiently. You cut operational costs and improve your bottom line. FineReport supports your cost-saving goals by providing detailed reports on inventory, production efficiency, and maintenance needs. You can quickly identify areas where you can reduce expenses and increase efficiency.

Tip: When you use a manufacturing management system, you not only increase efficiency but also ensure your production management supports long-term growth and profitability.

Implementation of Manufacturing Management System

Smart Factory Operation and Control Platform

When you start implementing a manufacturing management system, you face several challenges. You might need to set up new servers, networks, and devices. This technical work often requires experts. You also need to manage change among your team. Workers may resist new processes, and you must align everyone with the new direction. Costs can be high, covering software, hardware, and support. You must also follow industry regulations, which may require special solutions.

You often run into integration problems. Connecting your new system with existing ERP or legacy platforms can create data silos. Ensuring data quality and accuracy is another challenge. If you do not capture and validate data correctly, your decisions may suffer. You must also balance customization with standardization. Too much customization can make your system complex and expensive. Finally, user adoption is key. If your team finds the system hard to use, they may not engage fully.

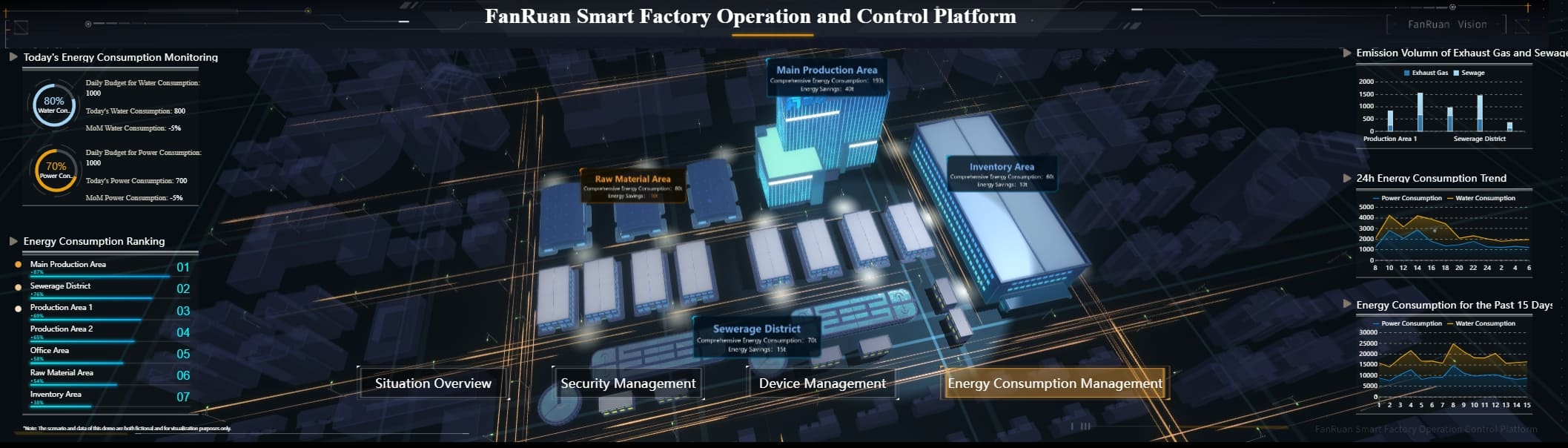

A smart factory operation and control platform helps you overcome these obstacles. It brings together data from connected machines and sensors, giving you real-time visibility into your manufacturing operations. Technologies like big data analytics, Industrial IoT, and AI support automation and better decision-making. You can monitor your plant in real time, track machine performance, and use predictive maintenance to reduce downtime. These platforms also help you optimize resource allocation and streamline your manufacturing operations management.

Tip: Smart factory platforms empower you to respond quickly to market changes, improve productivity, and drive innovation in your manufacturing operations.

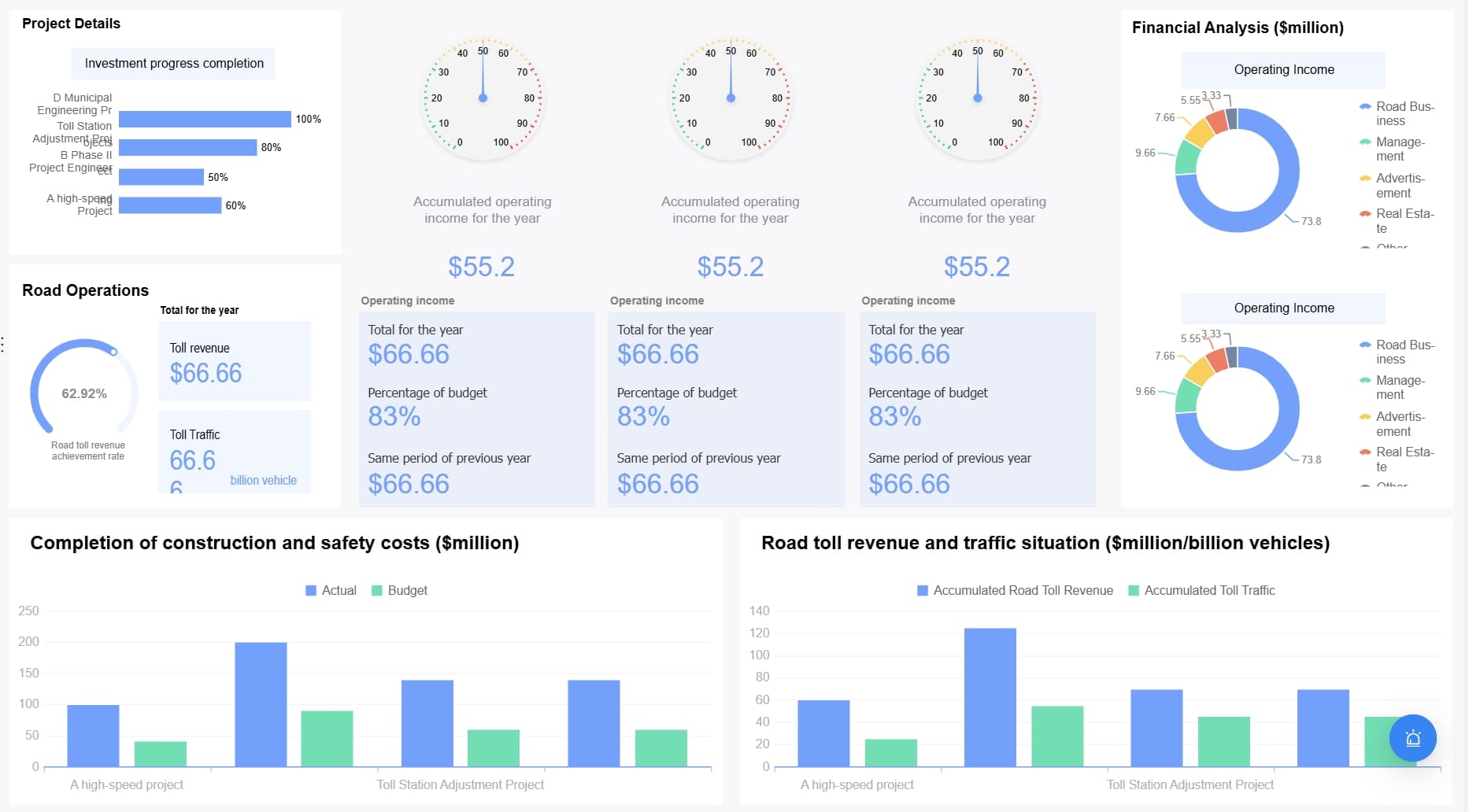

Project Details

To ensure a successful rollout, you should follow best practices:

- Plan beyond technical setup. Focus on how the system will affect daily operations and people. Communicate clearly with all stakeholders and provide tailored training.

- Test thoroughly before going live. Use a test environment that matches your real operations. Automated and stress testing help you find and fix issues early.

- Prioritize security. Conduct audits and use best practices like encryption and least privilege access.

- Stay flexible. Prepare rollback plans and use agile methods for incremental deployment. Design your system to scale as your manufacturing grows.

- Monitor and evaluate. Set clear KPIs for your manufacturing operations management, such as uptime and user satisfaction. Review progress regularly and seek continuous improvement.

FanRuan solutions support you at every step. The PDCA (Plan-Do-Check-Act) management system guides you through planning, execution, checking results, and acting on insights. FineReport consolidates data from all business modules into unified dashboards, making it easy to monitor your manufacturing operations. The FineOps platform ensures stable deployment by checking resources and reducing risks. These tools help you manage complex projects, assign tasks clearly, and drive continuous improvement in your manufacturing operations management.

Note: By following these strategies and using FanRuan solutions, you can overcome common challenges and achieve a smooth, successful implementation of your manufacturing management system.

Manufacturing management systems help you automate, monitor, and improve every part of your production process. You gain faster reporting, better quality, and real-time control. Digital solutions like FanRuan and FineReport give you powerful tools for data integration, visualization, and decision-making.

| Feature | Benefit for You |

|---|---|

| Real-Time Data | Quick, informed decisions |

| Custom Dashboards | Easy tracking of key metrics |

| Mobile Access | Manage operations anywhere |

- You can connect systems, avoid data silos, and scale as your business grows.

- Smart factories use AI and cloud platforms to boost efficiency and stay competitive.

- Adopting integrated, data-driven management prepares you for the future of manufacturing.

Click the banner below to try FineReport for free and empower your enterprise to transform data into productivity!

Continue Reading About Manufacturing Management System

What is Manufacturing Operations Management and Why It Matters

Best Manufacturing Management Software for Modern Factories

How to Create a Manufacturing Dashboard (Step-by-Step Guide)

FAQ

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

9 Best Supply Chain Tools for Smarter Management in 2026

Find the best supply chain tools for 2025 to boost efficiency, gain real-time insights, and achieve smarter management for your business.

Lewis

Dec 18, 2025

Top 10 Supply Chain Tracking Software for 2026

Compare the top supply chain tracking software for 2026 to boost visibility, automate workflows, and leverage AI analytics for smarter decisions.

Lewis

Dec 18, 2025

Top 10 Supply Chain Management Software for Small Businesses

See the top 10 supply chain management software comparison for small businesses in 2026. Compare features, pricing, and scalability to find your best fit.

Lewis

Dec 18, 2025