Production management helps you plan, direct, and control your manufacturing activities. You use production management to organize resources, schedule tasks, and track progress. This approach ensures you meet customer demand and deliver products on time.

Manufacturers face pressure to boost efficiency, maintain quality, and lower costs. Recent trends show that digital transformation, real-time monitoring, and AI integration drive better production tracking and reporting. The table below shows how companies benefit from strong production management:

| Company | Efficiency Improvement | Reporting Time Reduction | Cost Reduction |

|---|---|---|---|

| Trident Services | 70% faster report generation | 90% automation | N/A |

| Crescent Foundry | N/A | N/A | 40% cut in reporting costs |

| Alaric Enterprises | N/A | 60% reduction forecasting time | N/A |

Production management gives you the tools to respond quickly and stay competitive.

Production management in manufacturing refers to how you plan, coordinate, and control the processes that turn raw materials into finished products. You use production management to make sure every step, from sourcing materials to delivering the final product, runs smoothly and efficiently. This approach helps you meet customer demand, keep costs under control, and maintain high quality.

You might wonder how production management differs from related concepts. The table below shows the distinctions:

| Concept | Definition | Key Differences |

|---|---|---|

| Production | All processes from raw materials to finished products. | Includes both tangible and intangible inputs, such as financial aspects. |

| Manufacturing | The process of turning raw materials into finished products. | Focuses only on physical transformation, not on intangible aspects. |

Production management covers more than just making products. It involves production planning, production scheduling, and production control. These activities help you allocate resources, set targets, and monitor progress. You focus on production optimization to reduce waste and improve productivity. The key areas of manufacturing production management include resource allocation, workflow design, and quality assurance.

You rely on several core functions of production management to achieve success in manufacturing. The table below highlights these functions and their purposes:

| Function | Description | Purpose |

|---|---|---|

| Production Planning | Decides what, how much, and when to produce. | Forecast demand, set targets, and create schedules to meet customer needs and cut costs. |

| Quality Control and Assurance | Sets standards, inspects products, and takes corrective actions. | Ensure products meet quality standards and keep customers satisfied. |

| Continuous Improvement | Analyzes processes and makes changes to boost productivity and quality. | Remove inefficiencies, lower costs, and improve product quality. |

You use production management to address challenges like production bottlenecks, inefficient resource use, and quality control issues. Production scheduling and production control help you respond quickly to changes and avoid unplanned downtime. The functions of production management also support continuous improvement, which is vital for staying competitive.

Today, manufacturers like you face a shift from traditional methods to digital and data-driven production management. Digital tools now let you use predictive analytics, real-time decision-making, and process stability to improve outcomes. For example, data-driven production management can boost productivity by up to 20%. You can use predictive maintenance to reduce downtime and focus on prevention rather than inspection.

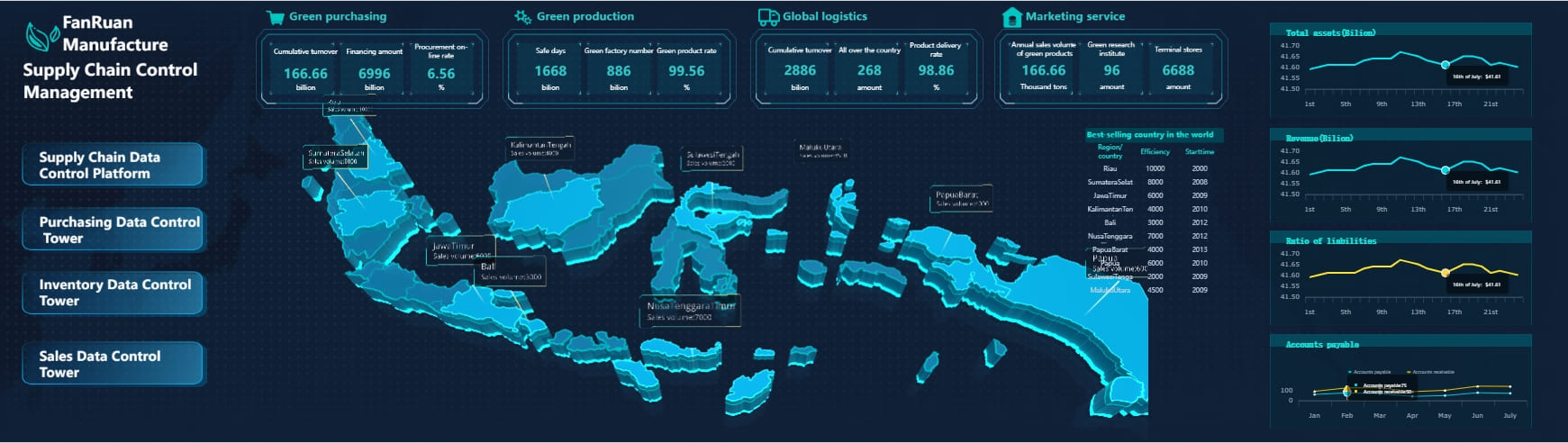

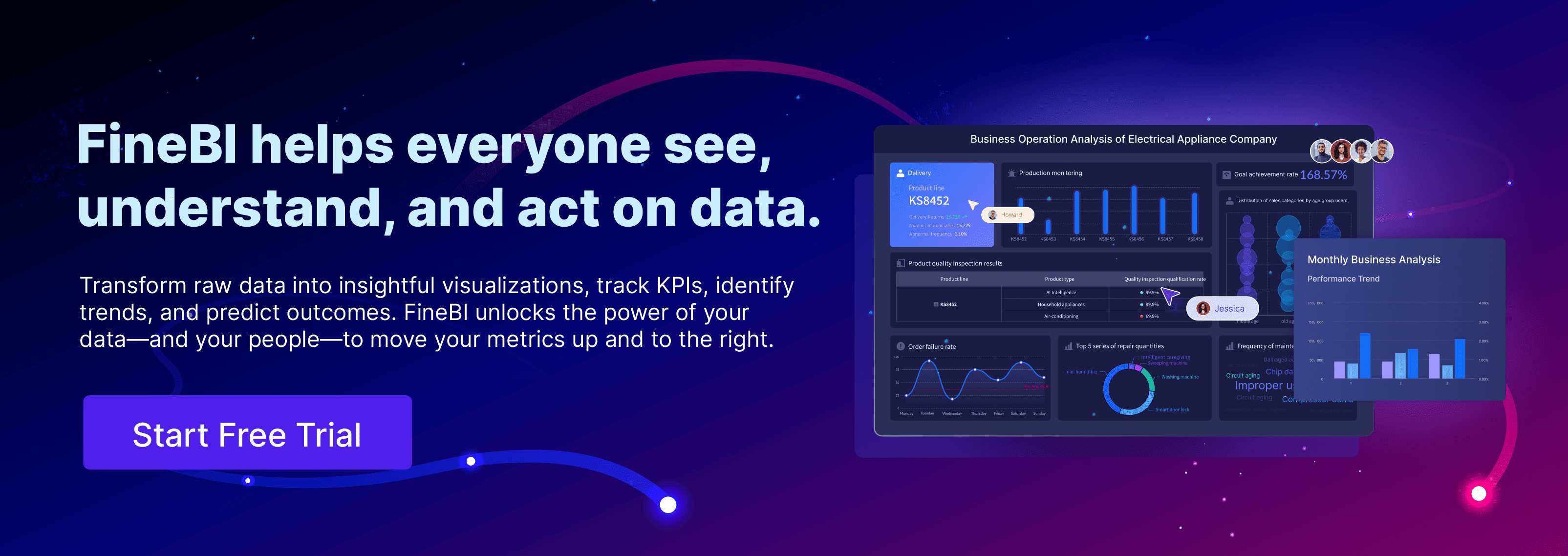

FineBI stands out as a modern tool that supports data-driven production management. With FineBI, you can integrate data from multiple sources, visualize key metrics, and make informed decisions faster. This approach helps you achieve production optimization and strengthens the importance of production management in your operations. By leveraging digital solutions, you gain better visibility into the key areas of manufacturing production management and drive continuous improvement.

You need production management to stay competitive and achieve long-term sustainability. When you use production management, you balance efficiency, quality, and cost control. This approach helps you respond to market changes and customer demands. The importance of production management becomes clear when you look at how it supports business growth.

Production management drives growth by improving planning, control, and process improvement. You identify the materials, labor, and equipment needed for production. You monitor each step to ensure quality and timely completion. You also focus on continuous improvement to boost productivity. The table below shows how production management supports business growth:

| Process | Description |

|---|---|

| Production Planning | Identifies materials, labor, machinery, and capital needed for production, ensuring optimal resource use. |

| Production Control | Monitors and manages the manufacturing process to ensure quality and timely completion of goods. |

| Process Improvement | Focuses on continuous improvement of efficiency and productivity through technology and workflow evaluation. |

| Maintenance of Equipment | Ensures regular checkups and preventive maintenance to avoid unplanned downtime and lost revenue. |

You benefit from production management because it ensures efficiency, maintains quality standards, and enhances responsiveness to market demands. These factors are crucial for business growth and help you build a strong market position.

Production management plays a key role in resource optimization. You use production management to analyze processes, identify bottlenecks, and improve resource use. By focusing on process visibility and waste reduction, you increase productivity and efficiency. Lean manufacturing principles help you maximize value and minimize waste. You also use real-time data analysis from IoT technology to understand system flow and enhance productivity.

Here are some ways production management leads to resource optimization:

Inventory management is another area where production management makes a difference. You track inventory levels, reduce excess stock, and avoid shortages. Effective inventory management helps you lower costs and improve cash flow.

Industry trends like agile manufacturing and digital transformation increase the importance of production management. Agile manufacturing allows you to adapt quickly to market changes. You prioritize speed, innovation, and responsiveness. Advanced systems like AI and IoT help you manage production in real time and improve supply chain efficiency.

The importance of production management extends to profitability and market share. Companies with strong production management often achieve higher market share and profitability. However, digital transformation changes how market share affects profitability. You need to focus on continuous improvement and technology integration to stay ahead.

Tip: Stakeholder engagement and sustainable practices enhance competitiveness in manufacturing. You should involve your team in lean and sustainable activities to drive value-added results.

Production management delivers measurable value across every stage of manufacturing. You can see the benefits of production management in cost savings, efficiency gains, quality assurance, and improved customer satisfaction. When you focus on production process improvement and use digital tools, you unlock even greater results. Let’s explore how you can achieve these outcomes in your operations.

You can achieve significant cost reduction through effective production management. By analyzing your production process, you identify areas where you can minimize waste, reduce downtime, and optimize resource allocation. For example, when you implement a tailored SMED (Single-Minute Exchange of Die) improvement program, you can reduce changeover time by 33%. In some cases, manufacturers have decreased bottleneck process changeover time by 30% within a year. These improvements lower labor costs, reduce material waste, and cut unnecessary movement.

You also benefit from quantitative modeling. This approach helps you balance workloads and minimize movement costs during the production process. When you use production management software, you gain real-time insights into your operations. You can track inventory, monitor equipment usage, and identify cost drivers. This data-driven approach supports production process improvement and helps you make informed decisions that lower your overall expenses.

The BOE customer story highlights the impact of digital production management. BOE used FineBI to integrate data, standardize metrics, and create a unified analysis framework. As a result, BOE reduced inventory costs by 5% and increased operational efficiency by 50%. These results show how you can achieve cost reduction by leveraging digital tools and focusing on continuous production process improvement.

Production management enables you to boost efficiency at every step of the production process. When you streamline workflows and eliminate bottlenecks, you produce more in less time. The table below summarizes common efficiency gains reported by manufacturers after implementing production management systems:

| Efficiency Gain | Description |

|---|---|

| Increased Productivity | You produce more units in less time. |

| Cost Reduction | You lower operational costs through efficient processes. |

| Improved Quality | You achieve higher product standards and fewer defects. |

| Shortened Lead Times | You deliver products to customers faster. |

| Enhanced Customer Service | You respond quickly to customer needs. |

| Increased Competitiveness | You compete more effectively in the market. |

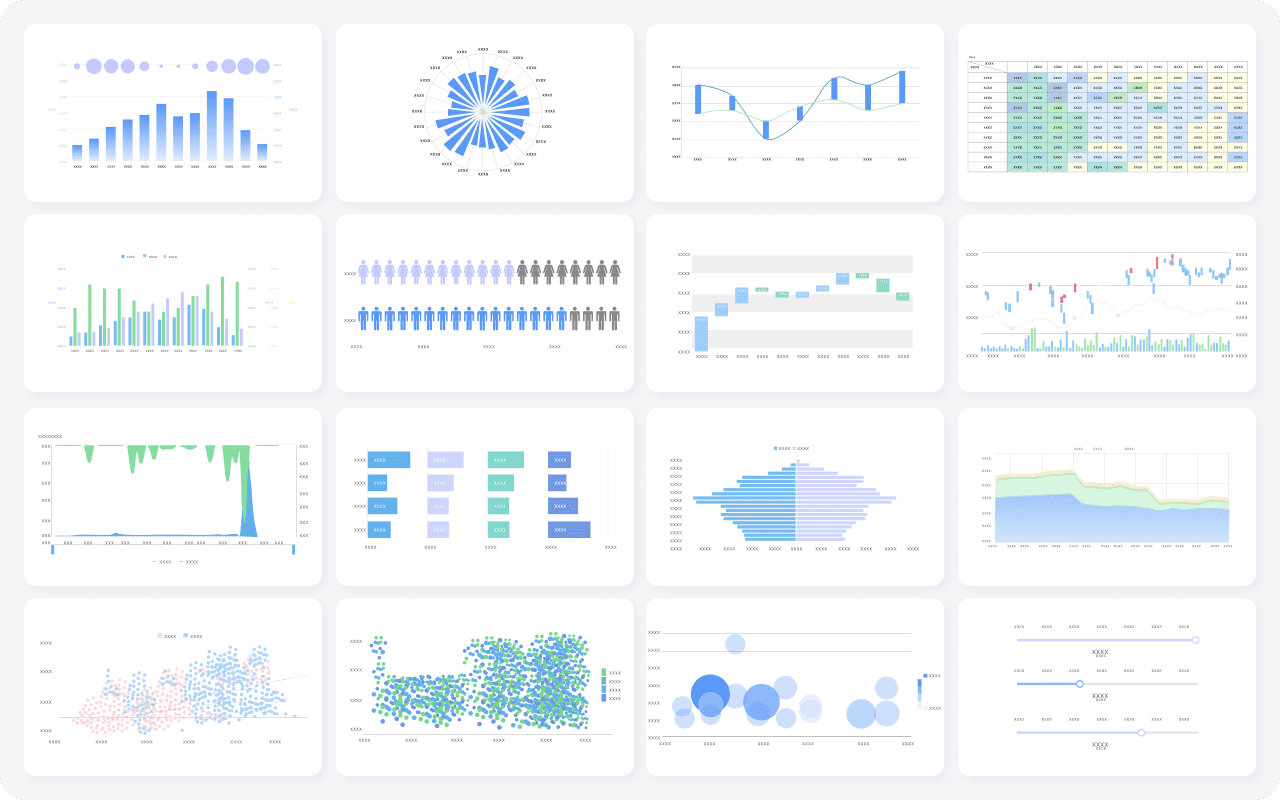

You can realize these efficiency gains by focusing on production process improvement. For example, you can automate routine tasks, use predictive maintenance, and monitor production lines in real time. These strategies help you reduce downtime and waste. When you use production management software like FineBI, you gain access to advanced analytics and real-time dashboards. This visibility allows you to make quick adjustments and keep your production process running smoothly.

BOE’s experience demonstrates the power of data-driven efficiency. By consolidating data and standardizing metrics, BOE improved cross-factory benchmarking and operational coordination. This led to a 50% increase in efficiency, showing how digital production management can transform your operations.

Quality assurance is a core benefit of production management. You set clear standards, inspect products, and take corrective actions to ensure every item meets your requirements. Production management helps you track key metrics that influence quality, such as cycle time, lead time, machine uptime, labor performance, and overall equipment effectiveness (OEE).

| Metric | Description |

|---|---|

| Cycle Time | Measures the total time from the beginning to the end of a process, impacting efficiency. |

| Lead Time | The time taken from the initiation of a process to its completion, crucial for timely delivery. |

| Machine Uptime | Indicates the operational time of machines, affecting production capacity and quality. |

| Labor Performance | Assesses the efficiency of labor, directly influencing productivity and quality outcomes. |

| Overall Equipment Effectiveness (OEE) | A comprehensive metric that evaluates the effectiveness of a manufacturing process. |

You can use production management software to monitor these metrics in real time. This approach supports production process improvement by identifying issues early and enabling quick corrective actions. Data-driven quality management allows you to spot potential defects before they reach the customer. As a result, you maintain high product standards and build a reputation for reliability.

Production management directly impacts customer satisfaction. When you deliver high-quality products on time, you build trust and loyalty with your customers. Companies that provide excellent service quality often outperform competitors in profitability and market share. Strong customer satisfaction links to higher ROI, better economic returns, and increased market value.

Data-driven quality management plays a key role here. You can identify defects early, take corrective action, and ensure products meet customer expectations. High-quality products improve customer satisfaction scores and net promoter scores. Proactive quality management also encourages customer loyalty and advocacy.

| Evidence Type | Description |

|---|---|

| Service Quality | Companies delivering high service quality outperform those with lower service quality in profitability and market share. |

| Customer Satisfaction | Strong positive relationships exist between customer satisfaction and ROI, economic returns, and market value. |

When you use production management to improve your supply chain management, you ensure timely delivery and consistent product quality. This reliability strengthens your relationships with customers and helps you stand out in a competitive market.

You can maximize the benefits of production management by adopting digital solutions. Here are some practical strategies:

FineBI provides a comprehensive platform for these strategies. You can connect data from multiple sources, visualize key metrics, and share insights across your organization. This approach supports continuous production process improvement and strengthens your supply chain management.

When you measure the return on investment for your production management initiatives, focus on metrics like net profit, ROI calculation, and resource allocation. These indicators help you prioritize projects, assess risks, and ensure sustainable growth.

Note: You can use key performance indicators such as overall operations effectiveness, total effective equipment performance, defect density, and right first time to evaluate your production management effectiveness.

By focusing on production management, production process improvement, and digital transformation, you position your manufacturing business for long-term success. The benefits of production management extend beyond the factory floor, driving efficiency, quality, and customer satisfaction throughout your supply chain management.

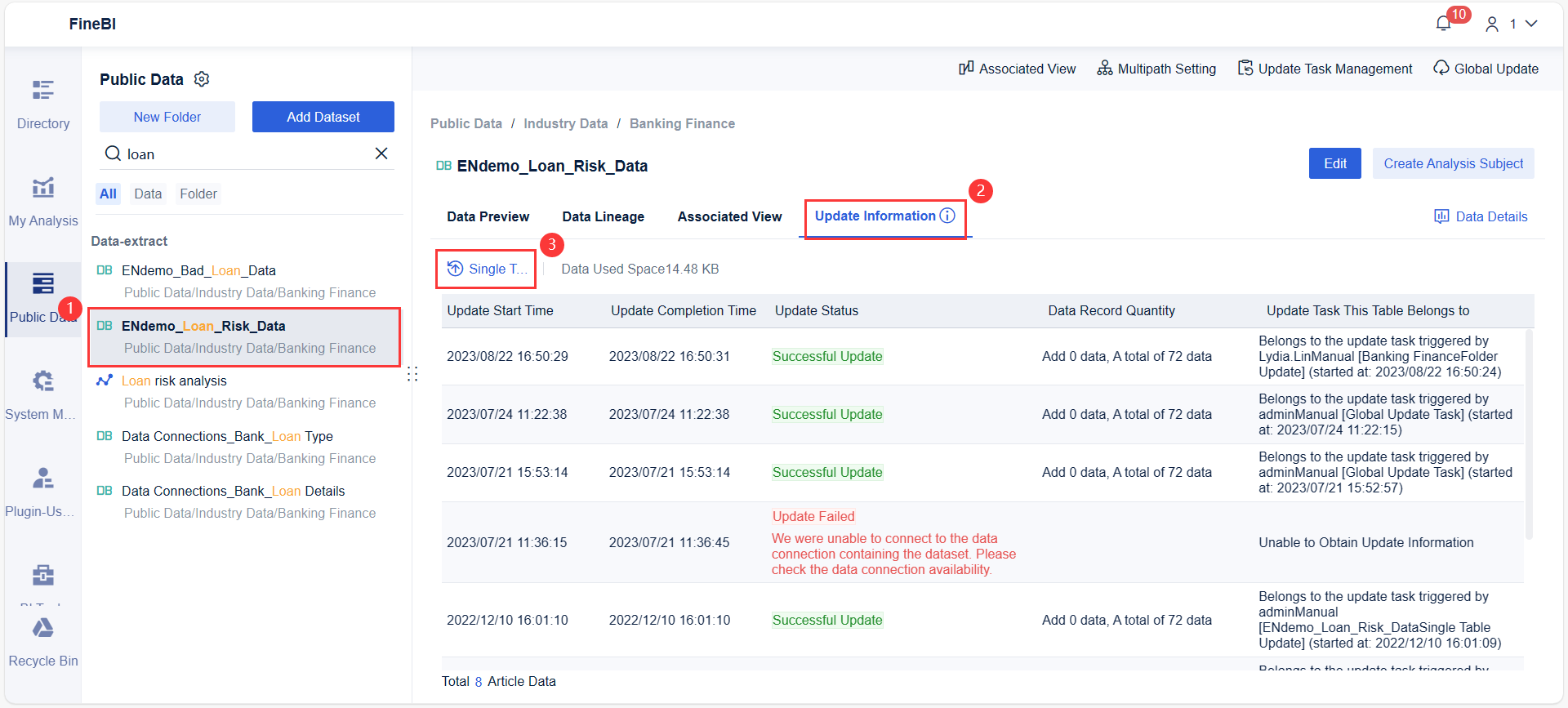

Modern production management relies on advanced technology to optimize every stage of manufacturing. You need strong data integration, real-time analytics, and collaborative tools to support capacity planning and continuous improvement. These technologies help you break down data silos and create a unified view of your operations.

Data integration is essential for effective production management. When you connect information from different departments, you streamline operations and reduce human error. This approach frees up time for high-value tasks like capacity planning and strategic decision-making. You also improve operational efficiency and cost savings. Automation enhances consistency and reduces mistakes, giving you a complete view of your customers and production lines. Data integration fosters better communication and collaboration across teams. Without it, data silos can slow down decision-making and create inconsistencies in your production management process.

Real-time analytics transform how you approach production management and capacity planning. You gain immediate insights into production metrics, which lets you make faster decisions. You can optimize resource allocation and use predictive maintenance to prevent equipment failures. Real-time analytics also improve quality control by detecting defects early. You can monitor current production rates, machine status, and labor efficiency as events happen. This level of visibility helps you streamline your supply chain and respond quickly to changes in demand. By analyzing data from every stage, you reduce downtime and improve both quality and cost control.

FineBI gives you a powerful platform for production management and capacity planning. With FineBI, you use self-service analytics to explore data without waiting for IT support. The tool connects to multiple data sources, making data integration simple and scalable. You can build real-time dashboards that display key metrics for your production management needs. FineBI supports collaborative decision-making, so your teams can share insights and work together on process improvements. The platform helps you implement lean and agile manufacturing practices by providing the data you need for continuous improvement. FineBI also offers strong data security features, including role-based access and data masking, to protect sensitive information. When you use FineBI, you ensure your production management system adapts to changing demands and supports sustainable growth.

Production management gives you clear advantages in manufacturing. You streamline processes, improve quality, and reduce costs. The table below highlights these benefits:

| Advantage | Description |

|---|---|

| Enhanced efficiency | Faster production cycles and lower operational costs. |

| Improved quality | Consistent standards through rigorous monitoring. |

| Cost reduction | Lower overall production costs by optimizing resources. |

| Timely delivery | Meet deadlines and customer demands efficiently. |

| Increased flexibility | Adapt quickly to market changes and customer needs. |

| Better decision-making | Use data for informed, proactive adjustments. |

| Employee productivity | Reduce downtime and improve workforce management. |

You should assess your current production management practices and consider digital tools like FineBI. Start by auditing your processes, setting clear goals, evaluating new technologies, and planning implementation. Real-time data and analytics help you optimize operations and support sustainable growth.

Production Dashboard: Optimize Your Production And Manufacturing

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

What is a data management platform in 2025

A data management platform in 2025 centralizes, organizes, and activates business data, enabling smarter decisions and real-time insights across industries.

Howard

Dec 22, 2025

Top 10 Database Management Tools for 2025

See the top 10 database management tools for 2025, comparing features, security, and scalability to help you choose the right solution for your business.

Howard

Dec 17, 2025

Best Data Lake Vendors For Enterprise Needs

Compare top data lake vendors for enterprise needs. See which platforms offer the best scalability, integration, and security for your business.

Howard

Dec 07, 2025