Manufacturing operations shape how you turn raw materials into finished products. These operations form the backbone of the global manufacturing sector, which is expected to reach $20.76 trillion by 2032. When you manage manufacturing operations well, you improve efficiency, reduce waste, and deliver quality products on time. Streamlined operations help you meet demand, avoid bottlenecks, and control costs, all of which support profitability. Many manufacturers now use digital platforms like FineReport to track operations, boost transparency, and stay competitive in a fast-changing market.

Manufacturing Operations Overview

What Are Manufacturing Operations

You encounter manufacturing operations every time you see a product move from raw material to finished item. These operations include a series of activities that help you manage, control, and improve how goods are made. Academic and industry sources describe manufacturing operations as a combination of production management, planning, scheduling, quality control, and maintenance. You use software systems like MES and SCADA to monitor and standardize these activities. The goal is to boost efficiency, maintain product quality, and reduce downtime.

Manufacturing operations focus on creating a smooth workflow. You optimize each step to avoid bottlenecks and ensure consistent results. When you follow industry standards, such as ISO 9001, you set up clear procedures and policies. This helps you meet regulations and deliver reliable products.

Here is a table showing the main components of manufacturing operations:

| Component | Description |

|---|---|

| Production Management | Oversee the entire manufacturing process, improve workflows, and reduce delays. |

| Production Planning & Scheduling | Align resources with demand and adjust schedules to keep production on track. |

| Quality Control | Monitor product quality, use data to prevent defects, and meet industry standards. |

| Maintenance | Manage equipment, prevent breakdowns, and use analytics for predictive maintenance. |

| Integration of Software Systems | Connect systems for real-time monitoring and process optimization. |

| Standardized Processes | Create uniform procedures to ensure consistency and continuous improvement. |

Key Processes in Manufacturing

You follow several key processes to keep manufacturing operations running smoothly. According to ISO standards, you start with preparation and planning. You train your team, analyze gaps, and set up a plan. Next, you document procedures and policies to make sure everyone knows what to do. You implement these steps, provide training, and focus on improving efficiency and quality.

You conduct internal audits to check compliance and fix any problems. Certification audits help you prove that your operations meet industry standards. Continuous improvement keeps your manufacturing processes up to date and competitive.

Digital manufacturing operations have changed how you work. You now use real-time data, AI, IoT, and automation to connect systems and make smarter decisions. This shift helps you respond faster to changes, reduce downtime, and customize products. Traditional manufacturing relied on manual processes and simple technology, which limited your ability to scale and innovate.

Tip: Embracing digital manufacturing operations lets you use platforms like FineReport to integrate data, monitor performance, and drive continuous improvement.

Components of Manufacturing Operations Management

Manufacturing operations management covers several core areas that help you run a successful factory. You need to focus on production management, quality control, and inventory and logistics. Each area plays a key role in making sure your manufacturing runs smoothly and meets customer needs.

Production Management

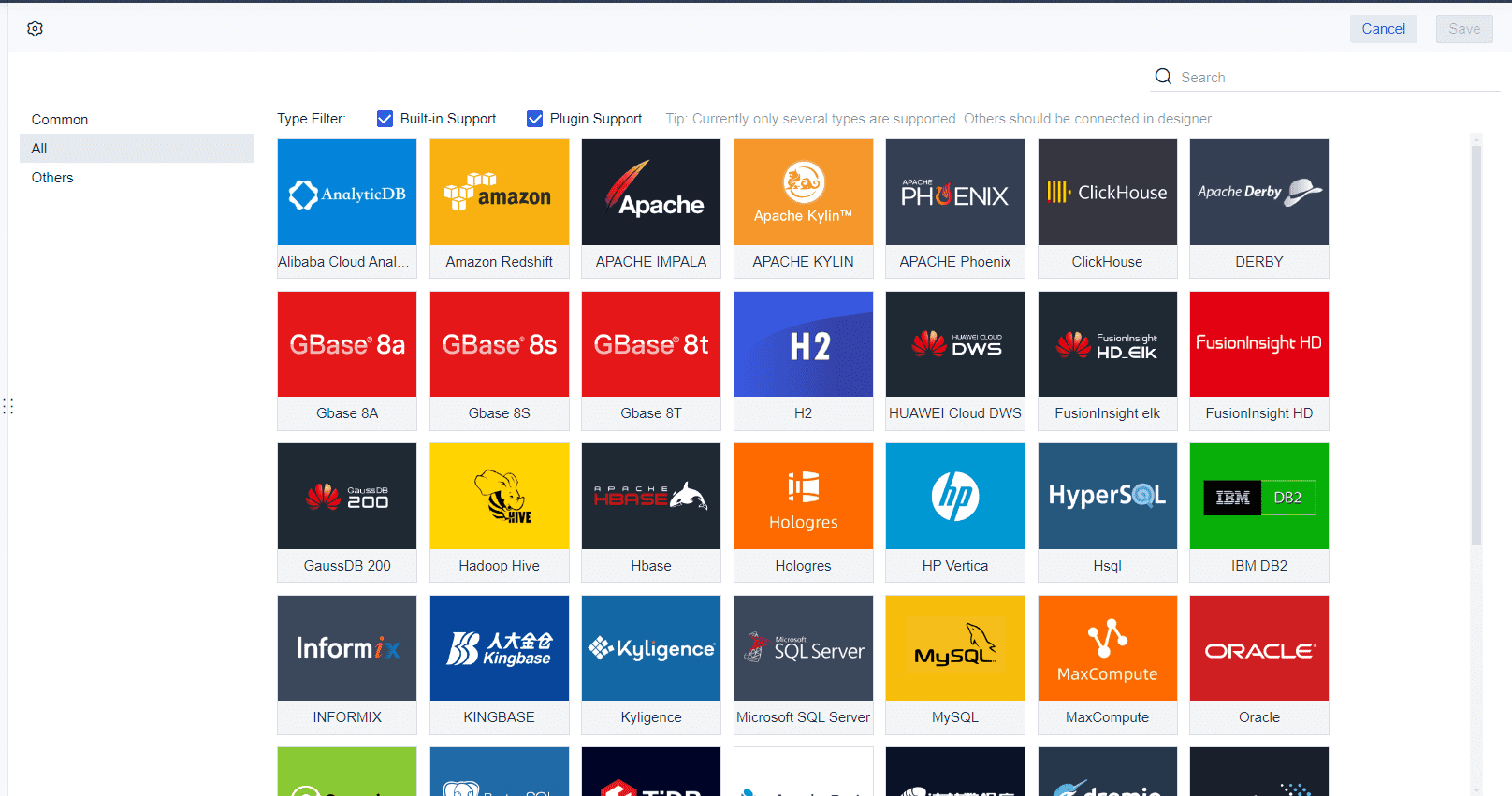

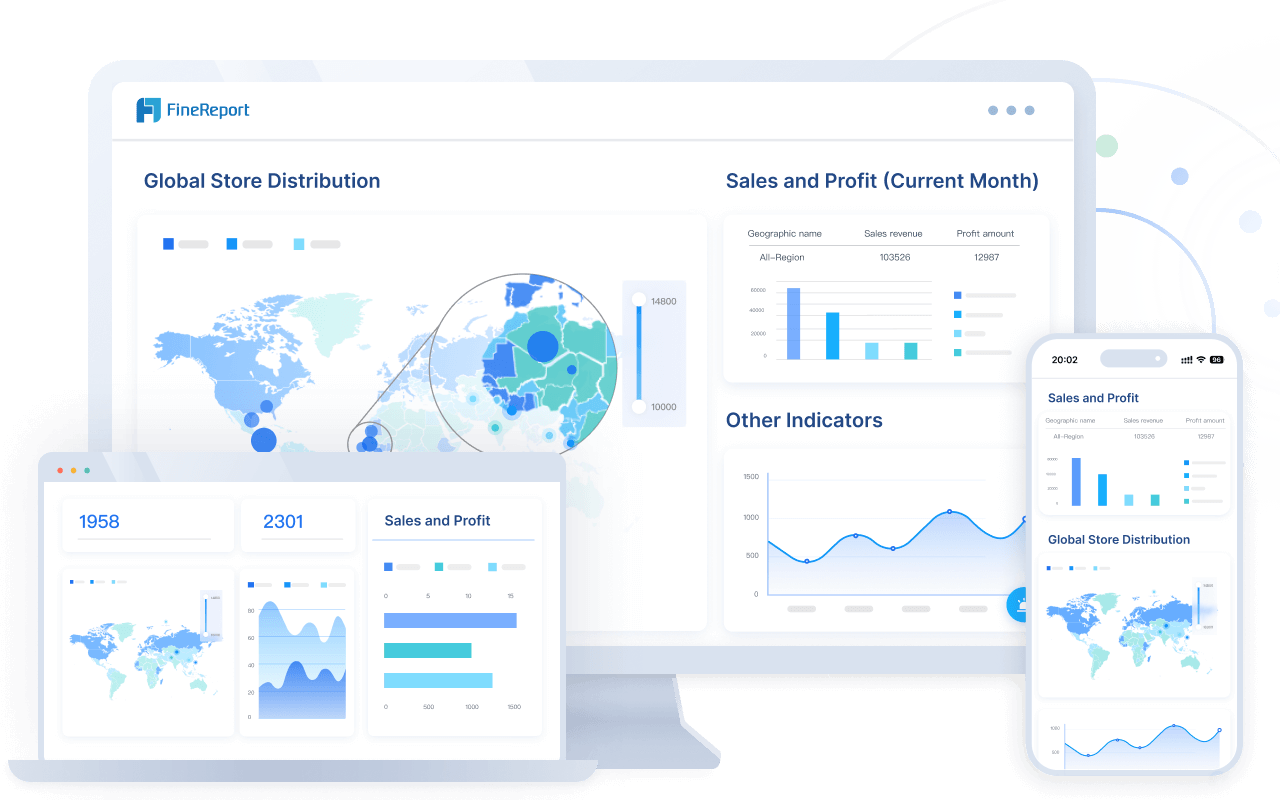

You start with production management, which guides how you plan, schedule, and control your manufacturing. This area includes production planning and control, resource allocation, and the use of manufacturing execution systems. You use forecasting to predict demand and set up schedules that match your resources with your goals. Top companies use lean manufacturing and just-in-time systems to reduce waste and improve flow. You can also use digital tools like FineReport to connect data from ERP and MES systems. These dashboards give you real-time updates, help you spot problems early, and support quick decisions.

Tip: When you use manufacturing execution systems, you track every step of production. This helps you find delays, fix issues fast, and keep your production on target.

Quality Control

Quality control ensures your products meet high standards. You use methods like ISO 9001, Six Sigma, and statistical process control to check for defects and improve processes. You train your team, set clear procedures, and use precise measuring tools. Many factories now use digital platforms to collect and analyze quality data in real time. FineReport lets you build dashboards that show quality trends, alert you to risks, and help you act quickly. This approach keeps your products reliable and your customers happy.

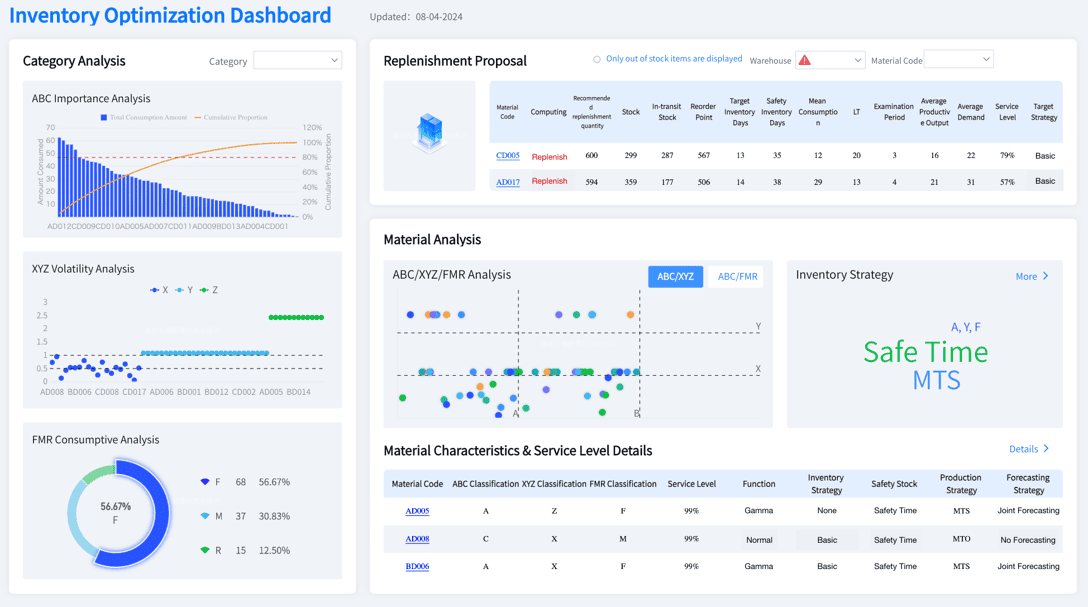

Inventory and Logistics

Managing inventory and logistics keeps your production running without delays. You forecast demand, track stock levels, and optimize warehouse space. You use automation, IoT, and cloud-based systems to monitor inventory and shipments. FineReport helps you see all your inventory data in one place, so you can avoid shortages or overstock. You also use analytics to improve delivery routes and reduce costs. By tracking key metrics, you make better decisions and keep your supply chain strong.

Note: When you use digital solutions for inventory and logistics, you gain real-time visibility and can respond faster to changes in demand or supply.

Importance of Manufacturing Operations

Manufacturing operations management plays a vital role in your business success. You rely on efficient operations to control costs, maintain high product quality, and keep customers satisfied. When you manage production performance well, you boost profitability and stay competitive in the global market.

Efficiency and Cost Control

You need efficient manufacturing operations to make the most of your resources. When you track production performance, you spot problems early and fix them before they grow. You use key metrics to measure how well your factory runs:

- Throughput: Number of quality products made in a set time.

- Overall Equipment Effectiveness (OEE): Combines machine availability, speed, and quality.

- Production Downtime: Time when machines are not working.

- Unit Costs: Cost to make each product.

- Asset Utilization: How well you use your equipment.

- Scrap Rate: Amount of wasted material.

Tip: FineReport helps you monitor these metrics in real time. You see dashboards that show production volume, downtime, and costs. This lets you make quick decisions and improve efficiency.

Many companies use data analytics to cut costs. For example, one manufacturer reduced inventory carrying costs by 15% each year by using analytics to optimize supply chain and inventory management. By renegotiating supplier contracts, the company increased operating margins by 12% in just two quarters. You can also save money by choosing better materials and redesigning products. For instance, changing the material and size of a truck fan cover led to a 25% reduction in material costs.

You can follow these steps to control costs:

- Use just-in-time inventory to avoid excess stock.

- Work with suppliers to get better prices.

- Track production costs and find ways to reduce waste.

FineReport supports these strategies by giving you clear reports and visualizations. You see where you spend the most and where you can save.

Product Quality and Compliance

You must deliver products that meet strict standards. Product quality affects your reputation and customer trust. You use several compliance standards to guide your manufacturing operations management:

- ISO 9001: Sets rules for quality management systems.

- Good Manufacturing Practices (GMP): Ensures safety and quality in regulated industries.

- HACCP: Focuses on product safety and risk control.

- Statistical Process Control (SPC): Uses data to monitor and improve quality.

You follow these steps to ensure quality and compliance:

- Identify the regulations for your products and industry.

- Develop a strategy to meet these rules.

- Set up a quality management system like ISO 9001.

- Run regular audits to check for problems.

- Train your team on procedures and standards.

- Use technology to track quality and compliance.

- Update your processes when regulations change.

Note: FineReport lets you build dashboards to track defect rates, audit results, and compliance status. You get alerts when something goes wrong, so you can act fast.

When you maintain high product quality, you avoid recalls, safety issues, and legal penalties. You also build trust with your customers and stand out from competitors.

Customer Satisfaction and Competitiveness

Your customers expect reliable products delivered on time. Manufacturing operations influence customer satisfaction through quality management, fast response to problems, and on-time delivery. You measure satisfaction using surveys, Net Promoter Score (NPS), and feedback. Key performance indicators include defect rates, delivery times, and response speed.

Recent surveys show that product recalls hurt customer satisfaction and brand reputation. Manufacturers now use AI and involve frontline workers to improve quality and responsiveness. For example, a semiconductor equipment maker uses annual customer surveys to guide improvements. The company resolves problems early, works with customers to plan new products, and provides strong technical support. These efforts lead to high satisfaction scores.

You can improve customer satisfaction by:

- Reducing defects and returns.

- Delivering products on schedule.

- Responding quickly to customer feedback.

FineReport helps you track these KPIs and analyze customer feedback. You see trends and act before issues affect your reputation.

Manufacturing operations also drive competitiveness. You use cost modeling to optimize resources and boost profitability. Investing in technologies like AI, robotics, and IoT increases efficiency and product quality. You can create new business models, strengthen your supply chain, and meet sustainability goals. Attracting skilled talent and balancing global reach with local needs helps you grow in new markets.

Tip: FineReport gives you the tools to monitor production performance, compare results, and make smart decisions. You stay ahead of competitors and adapt quickly to market changes.

Best Practices in Manufacturing Operations

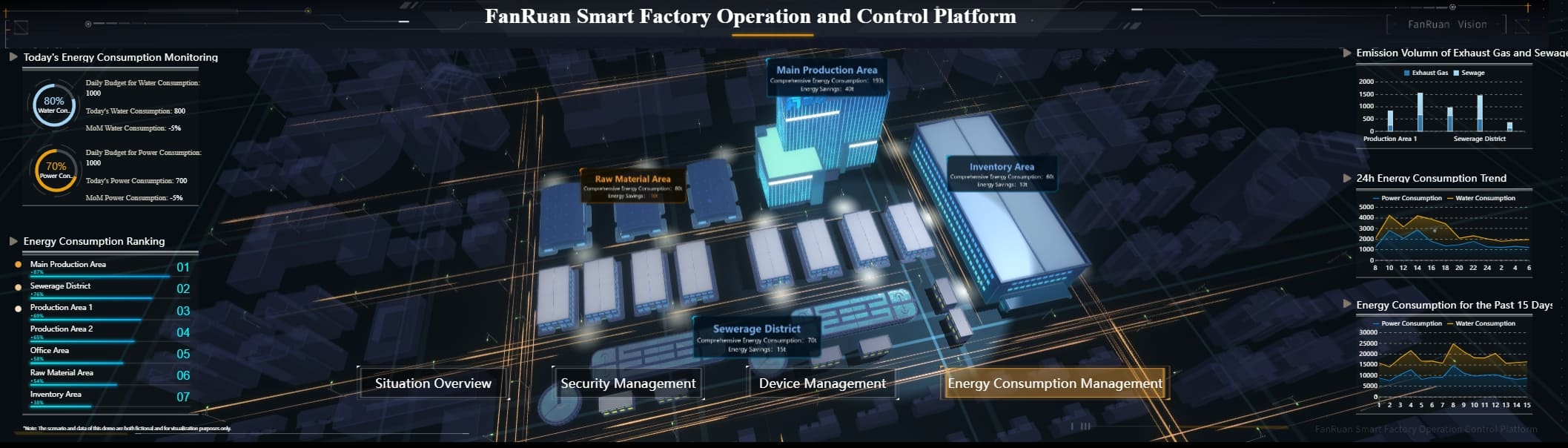

Smart Factory Operation and Control Platform

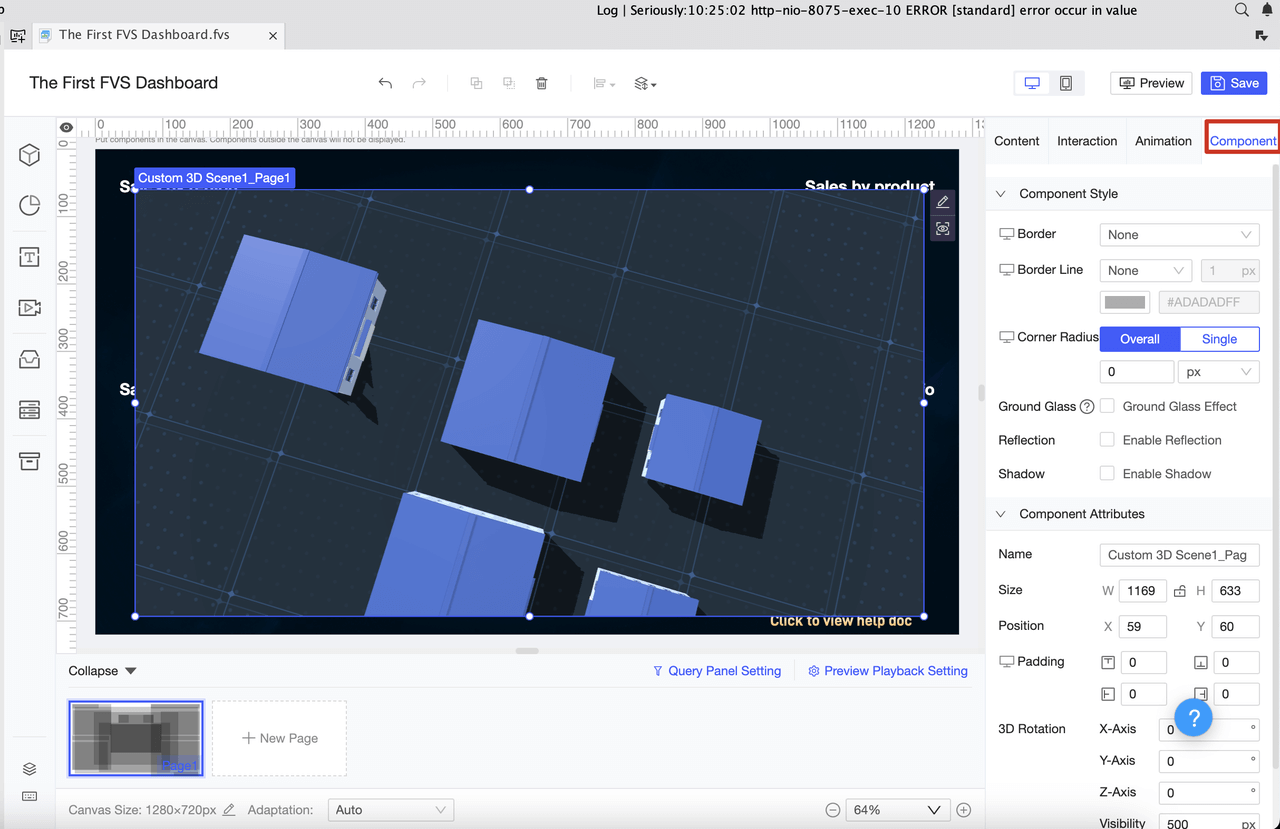

You can achieve world-class results in manufacturing by following proven best practices. Start by tracking and analyzing production data from interconnected equipment and sensors. This gives you real-time insights into every stage of your operations. When you identify bottlenecks and inefficiencies, you can target your efforts to optimise production and reduce downtime.

Smart factory platforms use technologies like AI, machine learning, and IoT to automate repetitive tasks and support your team. These systems collect data from workers, machines, and sensors, giving you a clear view of your factory floor. You can use this information to balance workloads, improve safety, and provide personalized training. Real-time dashboards help you monitor progress, spot issues, and make quick decisions.

Tip: FineReport lets you build custom dashboards and reports that connect to all your data sources. You can see trends, track KPIs, and get alerts when something needs attention. This helps you manage manufacturing operations efficiently and respond to changes right away.

Continuous improvement is key. Measure your progress over time, encourage feedback, and train your team to adapt to new technologies. When you foster a culture of innovation, you empower everyone to find better ways to work.

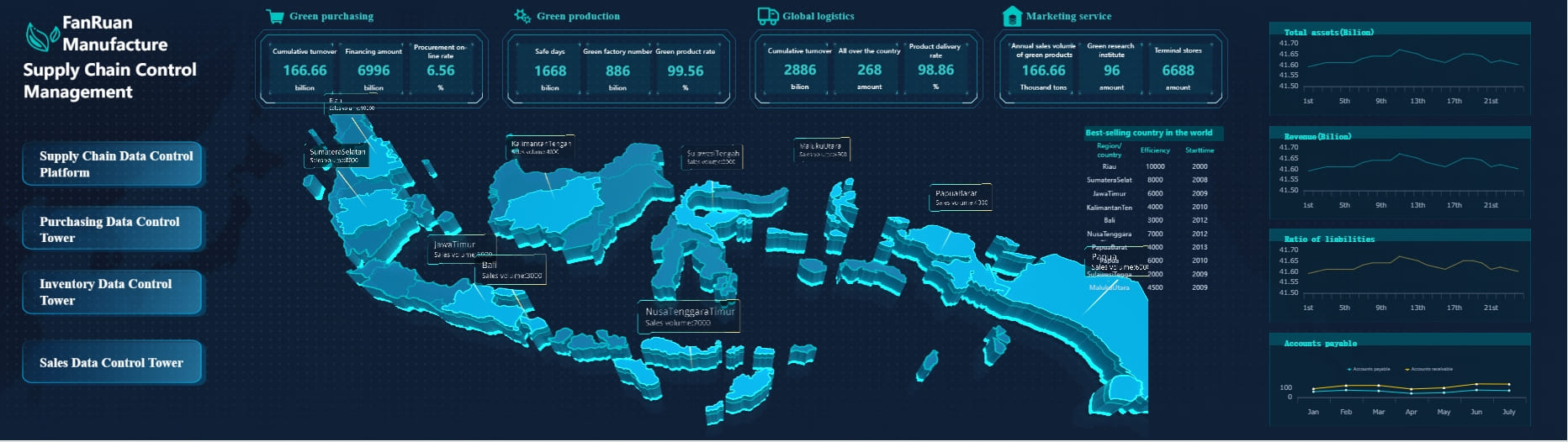

Supply Chain Management

Strong supply chain management keeps your manufacturing running smoothly. Use real-time analytics to monitor inventory, shipments, and supplier performance. Integrate data from ERP, WMS, and IoT devices to get a complete view of your supply chain. This helps you forecast demand, optimize inventory, and avoid shortages or excess stock.

You should also focus on risk management by planning for disruptions and building strong relationships with suppliers. Embrace green practices by reducing waste and choosing sustainable materials. Automation tools can track orders, manage inventory, and send alerts, reducing manual errors and improving efficiency.

Note: FineReport supports supply chain visibility by integrating data from multiple systems into one dashboard. You can track stock levels, shipments, and supplier performance in real time, making it easier to make informed decisions and keep your operations on track.

Manufacturing operations drive efficiency, product quality, and profitability in today’s industry. When you use data-driven insights and digital tools like FineReport, you gain real-time visibility, predict issues, and optimize workflows. Digital transformation with IoT and AI streamlines tasks, reduces downtime, and improves customer satisfaction. To measure progress, track metrics such as cycle time, machine uptime, and on-time shipments. Evaluate your current processes, integrate your data, and use analytics to guide improvements for long-term growth.

Regularly review your operations using dashboards and reports to stay agile and competitive.

Click the banner below to try FineReport for free and empower your enterprise to transform data into productivity!

Continue Reading About Manufacturing Operations

What Is a Manufacturing Management System and How It Works

What is Manufacturing Operations Management and Why It Matters

Best Manufacturing Management Software for Modern Factories

How to Create a Manufacturing Dashboard (Step-by-Step Guide)

FAQ

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

9 Best Supply Chain Tools for Smarter Management in 2026

Find the best supply chain tools for 2025 to boost efficiency, gain real-time insights, and achieve smarter management for your business.

Lewis

Dec 18, 2025

Top 10 Supply Chain Tracking Software for 2026

Compare the top supply chain tracking software for 2026 to boost visibility, automate workflows, and leverage AI analytics for smarter decisions.

Lewis

Dec 18, 2025

Top 10 Supply Chain Management Software for Small Businesses

See the top 10 supply chain management software comparison for small businesses in 2026. Compare features, pricing, and scalability to find your best fit.

Lewis

Dec 18, 2025