Manufacturing optimization means you improve production processes to boost efficiency and quality. You use real-time data, digital tools, and continuous improvement to spot problems and make production smoother. Most manufacturers now invest in smart manufacturing.

You can think of manufacturing optimization as a way to make your production run smoother, faster, and with fewer mistakes. In industrial engineering, experts define manufacturing optimization as the process of maximizing profit and minimizing costs by using mathematical models and digital tools. You use these methods to improve every part of your production, from planning to delivery. You look for ways to boost efficiency, cut waste, and raise quality. You also use software like ERP systems and advanced scheduling tools to help you make better decisions about production and resource allocation.

When you focus on production optimization, you aim to eliminate bottlenecks and reduce downtime. You want to make sure every step in your manufacturing processes adds value. You use real-time data to spot problems early and fix them before they grow. You also use simulation software to predict outcomes and find the best solutions for your production challenges. This approach helps you stay competitive, adapt to market changes, and meet customer expectations.

Tip: If you want to improve your production, start by collecting data from every part of your manufacturing. Use dashboards and automation tools to see where you can make changes. This will help you make faster decisions and keep your production running smoothly.

Manufacturing optimization relies on several key elements that work together to improve your production processes. You need to understand these elements to get the most out of your production optimization efforts.

Note: Digital tools play a big role in production optimization. You can use dashboards, custom workflows, and visual boards to track progress and measure performance. These tools help you prioritize changes and see results quickly.

You also need to focus on continuous improvement. You collect feedback from employees and use automation software to keep your production running even when key people are away. You measure process times to find bottlenecks and automate approvals to prevent delays. Methods like Catchball encourage collaboration and shared responsibility for production execution.

Production optimization is not a one-time project. You need to keep looking for ways to improve your manufacturing processes. You use data, digital tools, and teamwork to make your production more efficient, cost-effective, and adaptable. This helps you stay ahead in a competitive market and meet your customers’ needs.

When you focus on production optimization, you unlock real business value. You see measurable improvements in your daily operations and your bottom line. Companies that invest in manufacturing optimization report higher productivity, lower costs, and better use of resources. You can see these results in real-world examples:

| Company | Optimization Focus | Measurable Business Outcomes |

|---|---|---|

| Kraft LifeSavers (Grantek) | Manufacturing data capture, process documentation, automation, and standardization during plant migration | More efficient production, operational efficiencies, smoother plant relocation |

| Uber | Data-driven fulfillment and trip workflow optimization using advanced analytics and automation | Time and cost savings, improved service delivery, scalable operations |

| Accenture (One Washington) | Business process redesign with lean concepts and ERP automation in finance, procurement, and HR | Enhanced service delivery, process standardization, cross-process improvements |

You can achieve similar results by using production optimization to streamline your processes. When you reduce waste and automate repetitive tasks, you cut operational costs and boost profitability. Lean manufacturing and Six Sigma help you remove non-value-added activities and reduce variability. Automation and data analytics give you real-time insights, so you can spot bottlenecks and fix them quickly. This leads to less downtime and lower energy use.

Note: Cost optimization increases your profit margins by reducing production expenses without raising prices. It also enables you to offer competitive pricing, attract more customers, and maintain healthy margins.

Here are some ways production optimization impacts your business:

If you let operational costs rise, you risk shrinking your profit margins and losing your ability to invest in new products or technology. Eliminating non-value-added activities and investing in energy-efficient systems helps you stay competitive. You need disciplined cost management systems to align your strategy with execution, so you can adjust quickly and grow sustainably.

Production optimization gives you a strong edge in the global market. When you refine your manufacturing processes, you produce faster, lower your costs, and improve product quality. These improvements help you meet customer demands and comply with regulations.

Digital transformation plays a big role in boosting your competitiveness. Research shows that even a small increase in digital transformation leads to a measurable rise in competitiveness. You gain this advantage by improving productivity, investing in research and development, and building a skilled workforce. Digital tools like big data, AI, and IoT make your production smarter. You can forecast market demand better and deliver higher-quality products.

You need to respond quickly to market changes and customer demands. Here is how you can use production optimization to stay ahead:

Manufacturers who use these strategies reduce costs, improve lead times, and increase flexibility. You can maintain high service levels and adapt quickly to changing market conditions. For example, using AI-driven inventory control can cut carrying costs by up to 20%. Strong supplier relationships make your supply chain more agile, so you can respond faster to disruptions.

Production optimization also supports sustainability. You reduce carbon emissions and waste, which helps you meet environmental goals and appeal to eco-conscious customers. By optimizing your supply chain, you improve operational agility, supplier reliability, and product quality.

Tip: Continuous improvement is key. When you keep refining your production processes, you stay competitive and ready for whatever the market brings.

You can unlock the full potential of your production by using data analytics at every step. Data-driven strategies help you make smarter decisions and improve efficiency. Here are some of the most effective approaches:

You can also use advanced modeling techniques like probabilistic modeling and Monte Carlo simulations. These methods help you understand uncertainty and make your optimization efforts more reliable. Scenario analysis and ensemble modeling give you a clearer picture of how your production will perform under different conditions.

Manufacturers collect data from many sources, including IoT sensors, ERP systems, and quality management tools. By analyzing this data, you reduce downtime, improve product quality, and make better decisions. Data analytics supports continuous improvement by helping you track progress and adjust strategies quickly.

Tip: Start by collecting machine, process, and supply chain data. Use dashboards to visualize trends and identify areas for improvement.

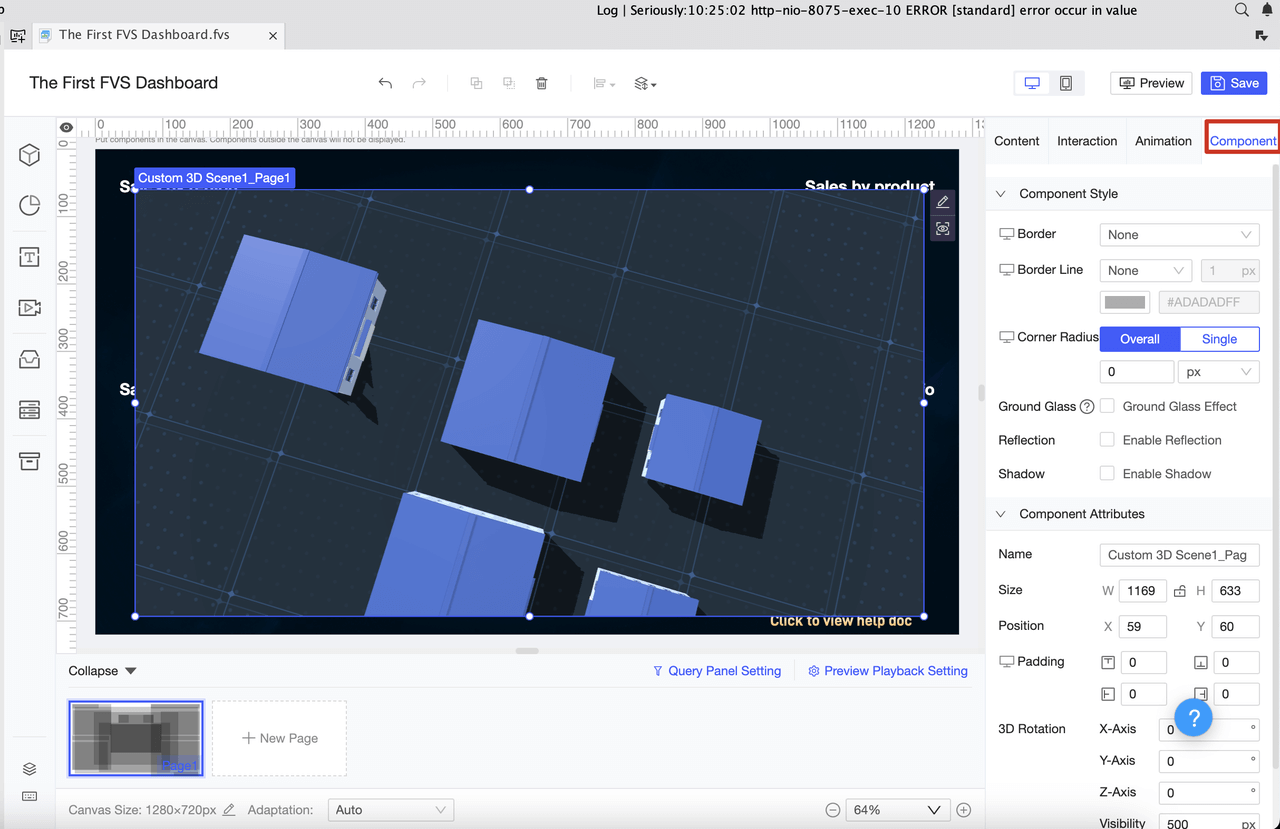

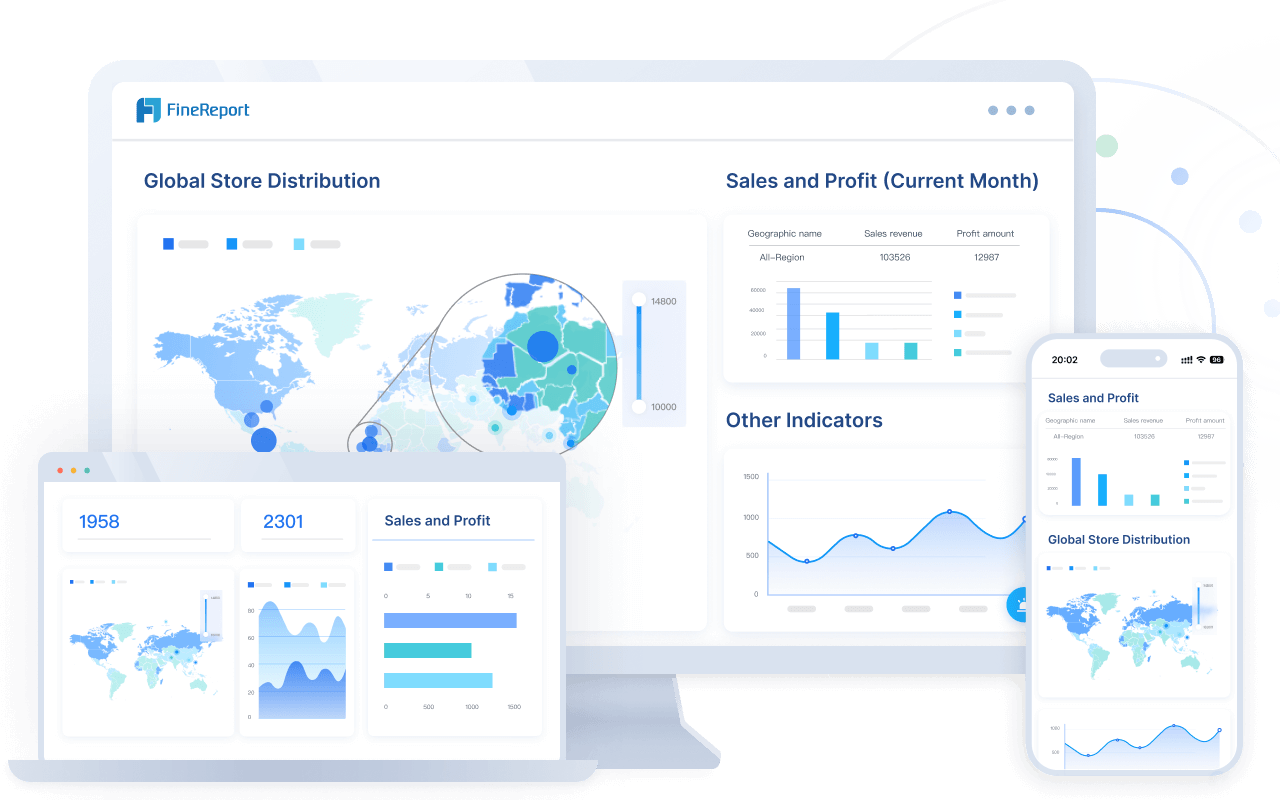

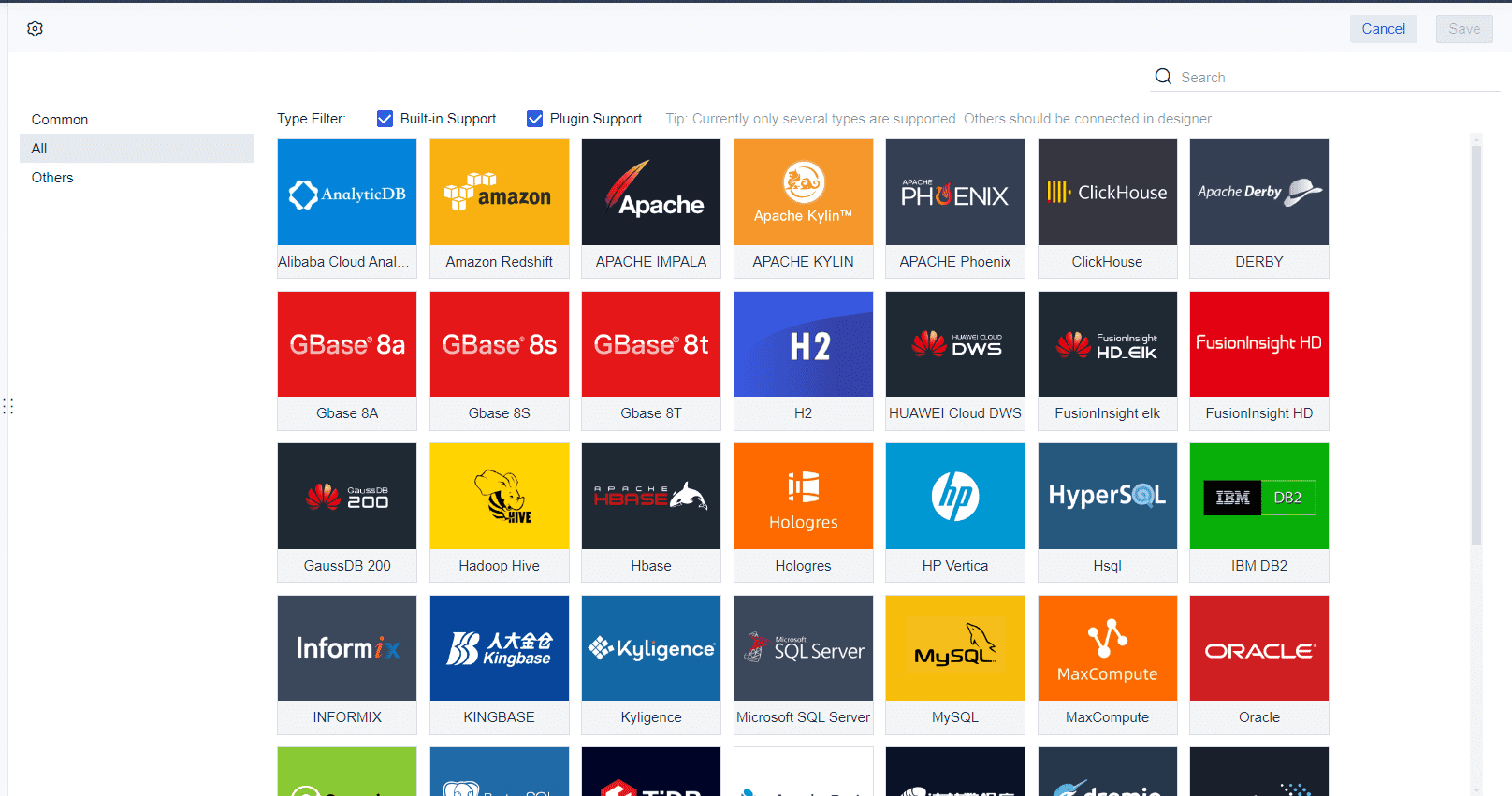

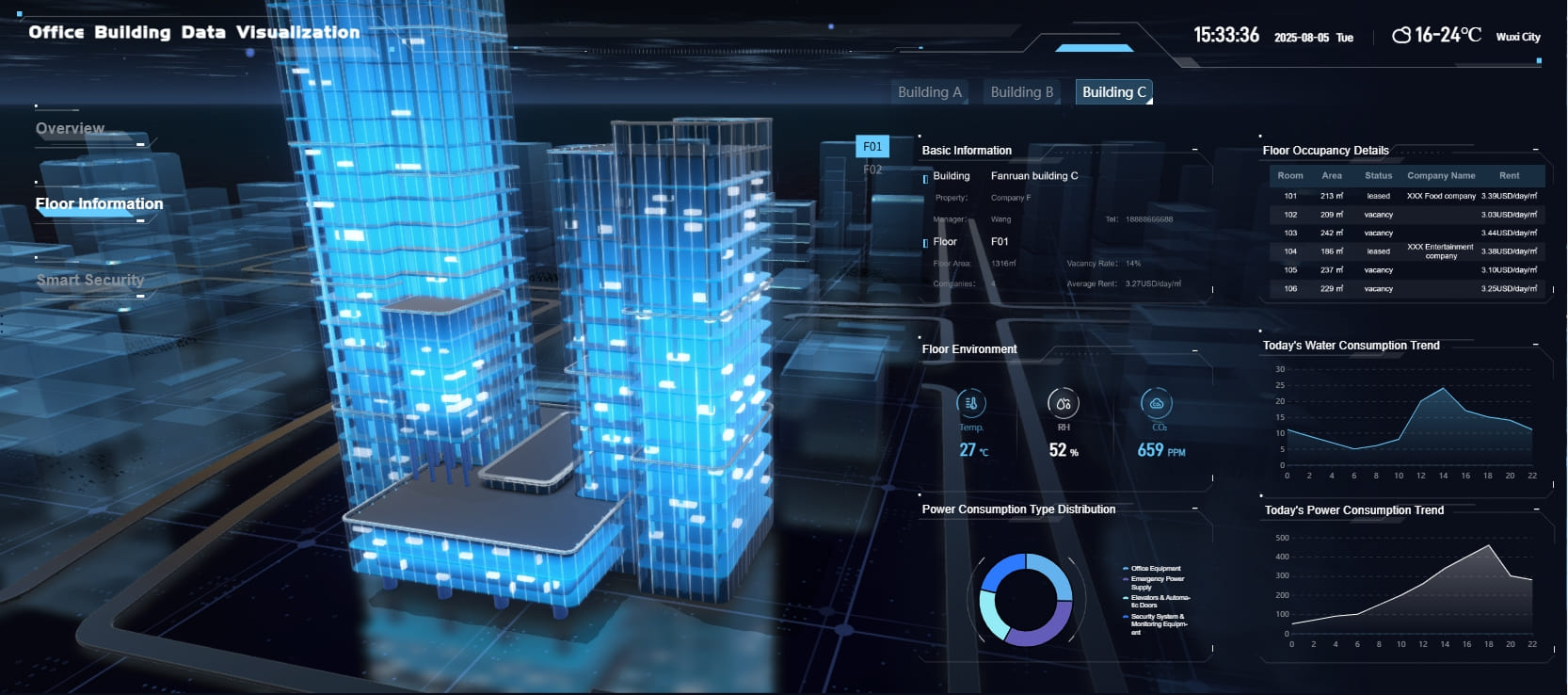

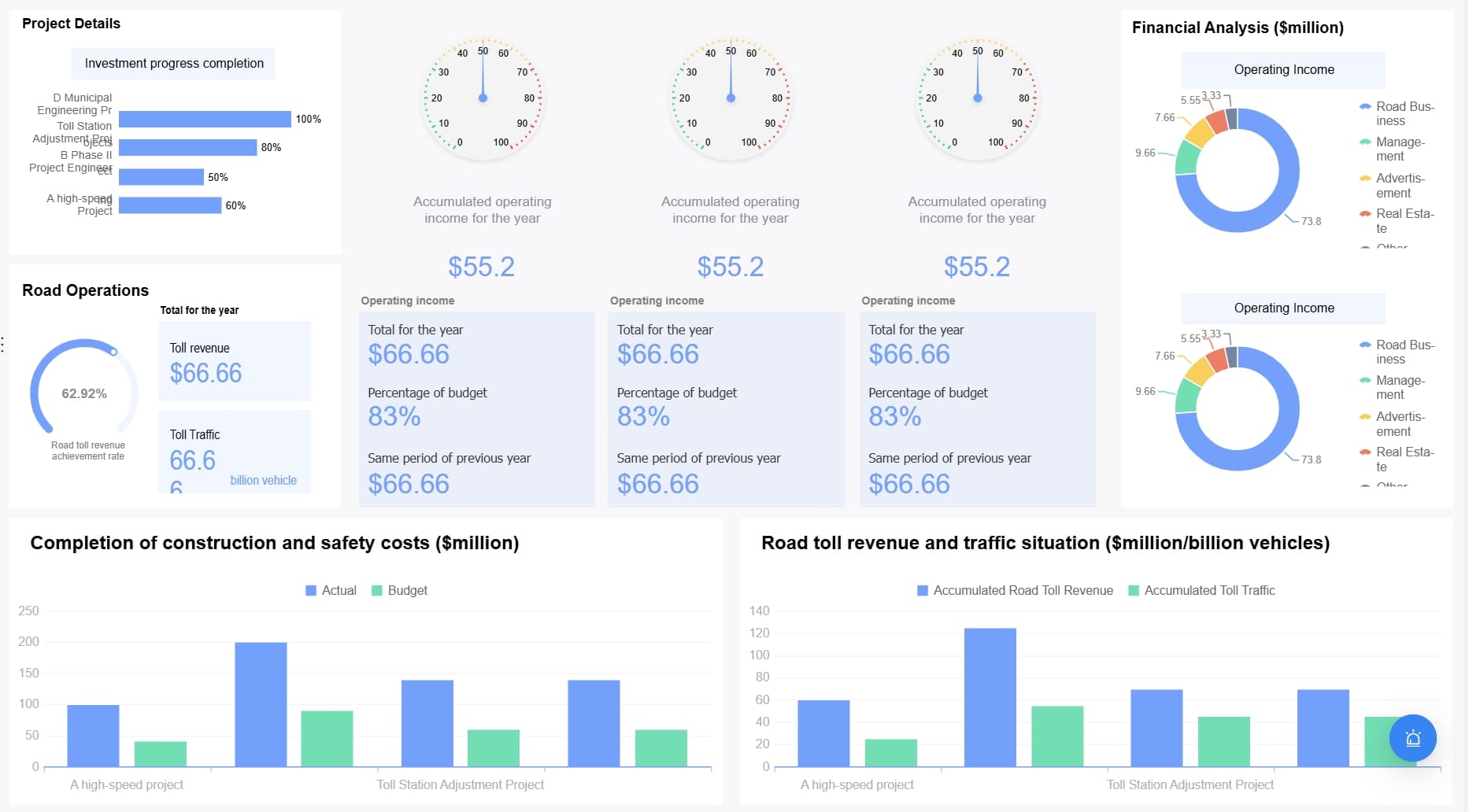

Digital tools play a key role in manufacturing optimization. FineReport by FanRuan stands out as a powerful solution for real-time data integration and visualization. You can monitor key metrics on advanced dashboards and spot trends instantly. The drag-and-drop interface lets you build custom reports, filter data, and drill down for detailed analysis.

FineReport connects with major business systems like SAP and Oracle ERP. This unifies your financial and operational data, making it easier to track KPIs. The software uses AI and machine learning to automate data preparation, detect anomalies, and generate predictive insights. You can access reports on any device, which supports fast decision-making on the shop floor or in the office.

With FineReport, you consolidate information from multiple sources. This ensures your reports always reflect the latest developments in your production. Real-time data analytics helps you respond quickly to challenges and drive continuous improvement across your manufacturing operations.

You can achieve significant efficiency gains by streamlining your manufacturing processes. When you use data-driven tools and continuous improvement methods, you maximize efficiency and boost productivity across your operations. For example, Ford used simulation and modeling to redesign its paint shop, which led to less waste and higher operational efficiency. Many manufacturers apply Lean and Six Sigma to eliminate waste, reduce defects, and improve consistency. You can track these improvements using real-time performance data and key metrics like Overall Equipment Effectiveness (OEE) and yield rate.

| Efficiency Metric | Improvement Percentage |

|---|---|

| Reduction in operational costs | 25-30% |

| Increase in productivity | Up to 35% |

| Reduction in defects/errors | 50% |

| Improvement in customer satisfaction | 30% |

| Increase in service delivery speed | 45-55% |

You measure increased productivity by collecting data from the production floor, focusing on cycle time, resource use, and yield. Automated data collection helps you respond quickly to issues, moving from reactive to proactive decision-making. This approach ensures you maximize efficiency and improve overall efficiency at every stage.

Manufacturing optimization helps you lower costs by streamlining workflows and using resources wisely. Companies like Nike have restructured their supply chains, partnering with efficient manufacturers to reduce overhead and improve supply chain efficiency. Walmart adopted RFID technology for real-time inventory tracking, which reduced manual errors and minimized holding costs. You can also cut costs by improving energy efficiency, reducing waste, and using automation to optimize labor and material use.

By focusing on these strategies, you not only reduce waste but also increase overall efficiency and profitability.

You can enhance product quality by streamlining processes and using advanced quality control measures. Lean manufacturing and Six Sigma help you minimize defects and maintain high-quality standards. Automation and robotics reduce human error, while predictive maintenance prevents equipment failures that could affect product quality. Real-time monitoring allows you to make quick adjustments, ensuring consistent results.

| Strategy/Technology | Contribution to Quality Improvement |

|---|---|

| Lean Manufacturing | Streamlines operations, improves productivity, and reduces defects. |

| Six Sigma | Reduces variability and defects, ensuring consistent high-quality output. |

| Automation and Robotics | Increases precision and enhances quality control. |

| Predictive Maintenance | Prevents downtime and defects caused by machine issues. |

| Industry 4.0 Technologies | Enables real-time monitoring and dynamic process adjustments for improved quality. |

Standardizing processes leads to consistent product quality and fewer returns. Continuous improvement ensures you keep refining your operations, embedding improved quality into your daily work. These practices help you meet customer expectations and strengthen your brand reputation by enhancing product quality and maximizing efficiency.

You may face several obstacles when trying to optimize your manufacturing operations. These barriers can slow progress and make it harder to achieve your goals:

Legacy systems also present a major challenge. Many factories rely on old technology that is hard to upgrade or connect with new digital tools. These systems often use outdated programming languages and can disrupt operations if replaced too quickly. Organizational culture can also resist change, especially when employees feel uncertain about new technologies or worry about job security. Without a shift toward adaptability, refining manufacturing processes becomes much harder.

You can overcome these challenges by using proven strategies and best practices. Start by adopting automation and digital tools. Robotics and automated systems increase speed and accuracy. Lean manufacturing helps you eliminate waste. Data analytics can identify bottlenecks, while predictive maintenance with IoT and AI reduces downtime.

Workforce productivity improves when you invest in training and use technologies like AR, VR, and IoT. Flexible work arrangements and career development programs also help keep employees engaged. Cybersecurity should be a priority as you adopt more digital tools. Regular assessments and employee training protect your systems and data.

Proactive equipment maintenance, using real-time sensor data, helps you schedule repairs before problems occur. Strategic planning and supply chain management also play a key role. Regular industry analysis, flexible business models, and supplier diversification reduce risk and improve resilience.

When you face resistance to change, prepare your team by raising awareness and involving them in planning. Communicate your vision clearly and celebrate short-term wins to keep motivation high. Embed changes into your company culture for lasting results. Structured change management models, like Kotter’s 8-step model, can guide you through the process.

Tip: Embrace Industry 4.0 technologies such as AI, 5G, and digital twins. These tools help you simulate and optimize your operations, making it easier to adapt and thrive in a competitive market.

You can start manufacturing optimization by setting up real-time monitoring and alert systems. These systems help you track every part of your production process. When you use real-time data analytics platforms, you see machine data and production status within seconds. You can set up alerts that notify you by email, SMS, or mobile app if something goes wrong. This lets you respond quickly and avoid bigger problems.

To make your monitoring effective, follow these steps:

You can use technologies like PLCs, DCS, and SCADA systems to support these efforts. Real-time monitoring helps you move from reactive to predictive maintenance. Predictive analytics can forecast equipment breakdowns, so you schedule repairs before failures happen. This approach keeps your equipment running longer and reduces costs.

You need clear and actionable data to make good decisions. Data visualization tools help you turn complex information into easy-to-understand charts and dashboards. When you use the right formats, you spot trends, track KPIs, and respond to issues faster.

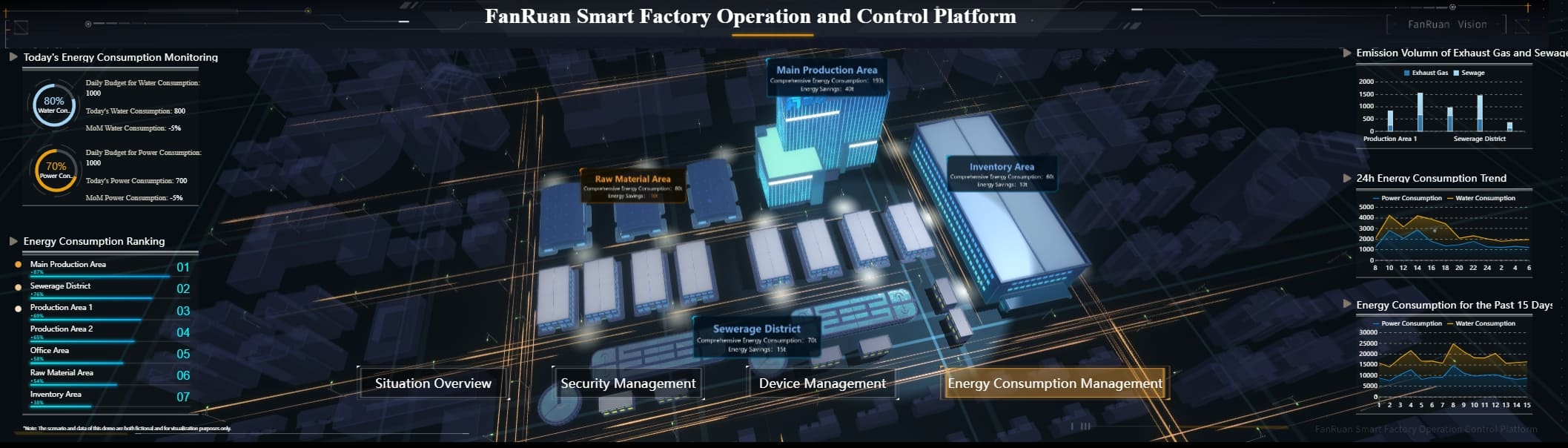

A 3D dashboard lets you explore data in three dimensions. You can see how different parts of your factory interact. This makes it easier to find bottlenecks and improve production planning. Augmented reality and virtual reality tools help you interact with data, making complex relationships more intuitive. Many manufacturers report less assembly time and fewer errors after using 3D dashboards.

A general dashboard gives you a real-time view of key metrics. You can customize it to show the most important KPIs for your team. Drill-down features let you investigate problems in detail. Consistent design and easy access mean everyone can use the dashboard, even without technical skills. Sharing visual data across teams helps everyone stay aligned and supports a data-driven culture.

When you focus on implementing new technologies and use diverse visualization formats, you improve decision-making, reduce downtime, and boost efficiency.

Manufacturing optimization helps you achieve sustainable growth and stay competitive. When you use data-driven processes, you improve efficiency, reduce waste, and make smarter decisions.

Click the banner below to try FineReport for free and empower your enterprise to transform data into productivity!

What is Manufacturing Operations Management and Why It Matters

Best Manufacturing Management Software for Modern Factories

How to Create a Manufacturing Dashboard (Step-by-Step Guide)

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

9 Best Supply Chain Tools for Smarter Management in 2026

Find the best supply chain tools for 2025 to boost efficiency, gain real-time insights, and achieve smarter management for your business.

Lewis

Dec 18, 2025

Top 10 Supply Chain Tracking Software for 2026

Compare the top supply chain tracking software for 2026 to boost visibility, automate workflows, and leverage AI analytics for smarter decisions.

Lewis

Dec 18, 2025

Top 10 Supply Chain Management Software for Small Businesses

See the top 10 supply chain management software comparison for small businesses in 2026. Compare features, pricing, and scalability to find your best fit.

Lewis

Dec 18, 2025