You face many challenges in today’s global marketplace. Almost 80% of organizations have experienced at least one major supply chain disruption in the past year. Over the past two years, 11% of companies reported incidents linked to supply chain risks. The supply chain risk management process helps you identify, assess, and address these threats. By using supply chain risk management, you can improve business continuity and build supply chain resilience. This structured approach gives you the confidence to handle disruptions and adapt to changing conditions.

The supply chain risk management process gives you a structured way to protect your business from disruptions. You can follow several key steps to identify, assess, and reduce risks. Many organizations use a risk assessment framework to guide their actions. These frameworks help you stay organized and focused as you manage threats to your supply chain.

You start the supply chain risk management process by identifying risks that could affect your operations. This step helps you build a clear risk profile for every part of your supply chain. You need to look at both internal and external factors. Common sources of risk include poor supplier performance, demand planning complexity, global labor shortages, inflation, and cyber threats.

Tip: Mapping out your supply chain and assessing supplier stability can help you spot hidden risks early.

You can use several methods to identify risks:

| Method of Risk Identification | Description |

|---|---|

| Financial Risks | Risks related to the financial stability of suppliers and market fluctuations. |

| Geopolitical Risks | Risks arising from political instability or changes in trade policies. |

| Environmental Risks | Risks associated with environmental regulations and natural disasters. |

| Operational Risks | Risks linked to internal processes and supply chain operations. |

You should also consider the most frequent sources of risk in global supply chains:

Several risk assessment frameworks can guide you during this stage. For example, the Acquisition Security Framework (ASF), ISO 31000, ISO 27001, and the NIST Cybersecurity Framework (CSF) all provide structured approaches for identifying and managing risks.

| Framework Name | Description |

|---|---|

| Acquisition Security Framework (ASF) | Emphasizes structured approaches to manage risks in supply chains, consistent with ISO, NIST, and DHS guidelines. |

| ISO 31000 | Flexible framework that encourages organizations to implement risk management processes tailored to their needs. |

| ISO 27001 | Focuses on managing supplier information security risks, assessing data access and incident history. |

| NIST Cybersecurity Framework (CSF) | Provides structured controls for evaluating a supplier’s cybersecurity preparedness across five key areas. |

Once you identify risks, you need to assess their potential impact and likelihood. This risk assessment process helps you decide which threats need the most attention. You can use a risk assessment framework to make this step more effective.

Many organizations use quantitative tools to measure risk. These tools help you understand how likely a risk is to happen and how much damage it could cause. Some of the most common tools include:

| Tool/Method | Description |

|---|---|

| Monte Carlo Simulation | Models various scenarios and shows the potential impact of different risk mitigation strategies. |

| Six Sigma Software Tools | Provides statistical analysis and risk modeling capabilities. |

| R and Python | Useful for custom simulations to evaluate complex supply chain risks. |

| Excel-based Tools | Helps create risk assessment dashboards and probability matrices. |

| Failure Mode and Effects Analysis (FMEA) | Quantifies severity, occurrence, and detection to assess risks effectively. |

You should involve stakeholders from different departments to get a complete view of each risk. After you collect data, use a risk prioritization matrix to rank risks by their likelihood and impact. This matrix helps you focus on the most serious threats first.

| Step | Description |

|---|---|

| 1 | Involve stakeholders to gather diverse expertise and perspectives for accurate risk assessments. |

| 2 | Use a risk prioritization matrix to evaluate risks based on likelihood and potential impact. |

| 3 | Map risks onto the matrix to categorize them into high, medium, or low priority. |

| 4 | Regularly update the matrix to reflect new or evolving risks, ensuring focused risk management efforts. |

After you assess and prioritize risks, you need to take action to reduce their impact. This step in the supply chain risk management process is called risk mitigation. You can use several strategies to protect your supply chain.

| Strategy | Description |

|---|---|

| Supply Chain Mapping | Visual representation of the supply chain to identify vulnerabilities and dependencies. |

| Weighted Ranking | Prioritizing risks based on their potential impact and likelihood. |

| Value at Risk (VaR) Assessment | Quantifying potential losses in the supply chain under different scenarios. |

| Supplier Segmentation | Categorizing suppliers based on risk levels to manage them effectively. |

| Diversification | Using multiple suppliers to reduce dependency on a single source. |

| Inventory Management Adjustments | Modifying inventory levels to buffer against supply disruptions. |

| Scenario Planning | Preparing for various potential future scenarios to enhance responsiveness. |

| Strong Supplier Relationships | Building partnerships with suppliers to improve communication and collaboration during crises. |

You can also diversify your supplier base to reduce the risk of regional disruptions. Adjusting inventory levels and building strong relationships with suppliers can help you respond quickly to unexpected events. Scenario planning prepares you for different types of disruptions, so you can act fast when problems arise.

To measure the success of your risk mitigation efforts, track key metrics such as key risk indicators (KRIs), risk control effectiveness, and incident frequency. These metrics show you how well your safeguards work and where you need to improve.

Note: Regularly review your risk management framework to keep up with new threats and changing business needs.

You need to monitor risks continuously to keep your supply chain resilient. Risk monitoring helps you detect threats early and respond quickly. You can track events and incidents that might disrupt your supply chain, such as natural disasters or geopolitical conflicts. Real-time monitoring gives you visibility into suppliers, manufacturers, and activities across your network.

You can use advanced technologies to improve your risk monitoring process. These tools help you collect and analyze data from different sources. The table below shows common technologies used for real-time risk monitoring in supply chains:

| Technology | Description |

|---|---|

| Data Analytics Tools | Predicts and prevents supply network interferences, alerts to possible machinery failures. |

| Internet of Things (IoT) | Uses smart devices for real-time monitoring, providing up-to-date information on goods' condition. |

| Artificial Intelligence | Analyzes large data sets to predict/manage risks, optimizes logistics routes, improves demand forecasts. |

| Blockchain | Records transactions on a secure ledger, verifies product authenticity, reduces fraud and errors. |

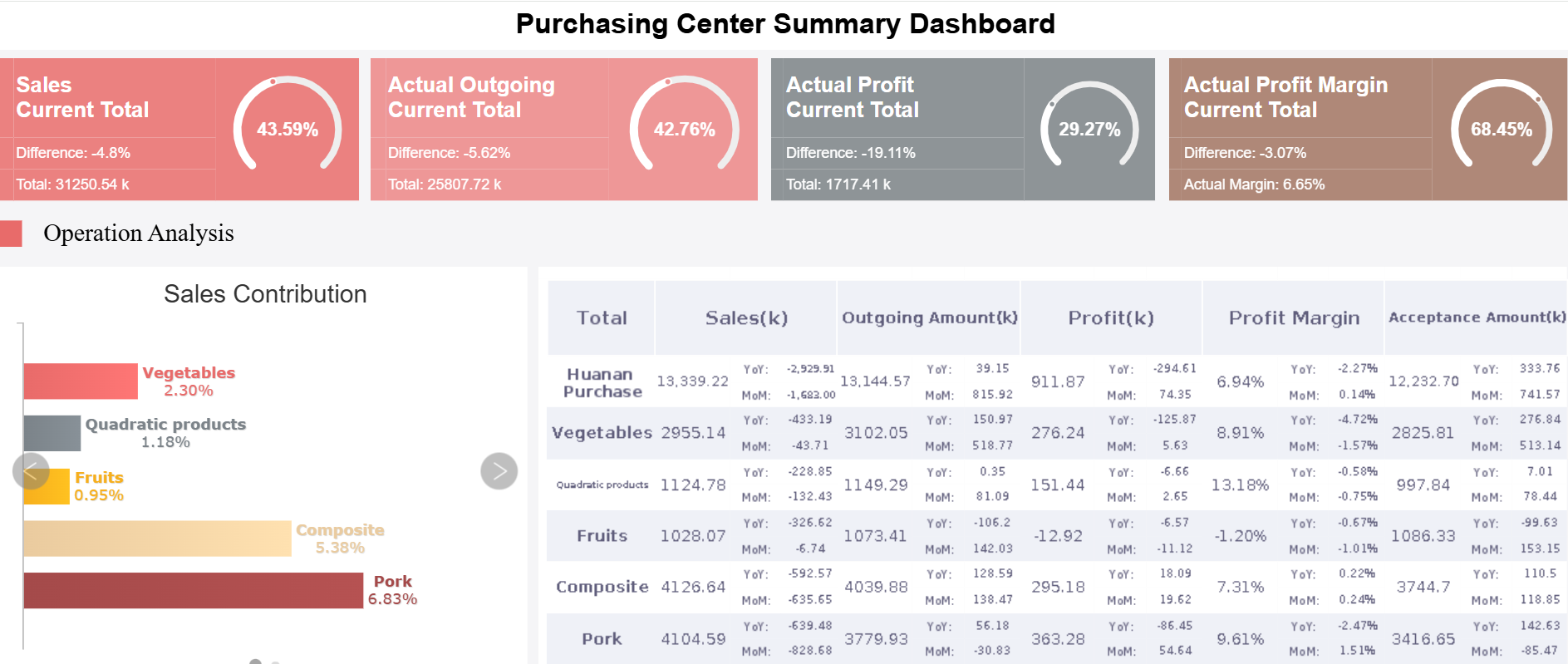

You can set up dashboards to visualize risk indicators and track changes in real time. These dashboards help you spot trends and patterns that might signal a problem. You can also use alerts to notify your team when a risk reaches a critical level. By monitoring risks closely, you can make better decisions and protect your supply chain from unexpected disruptions.

Tip: Use real-time monitoring tools to gain visibility into every part of your supply chain. This approach helps you respond faster to threats and maintain business continuity.

You need to review and improve your supply chain risk management process regularly. This step ensures your strategies stay effective as risks change over time. You should establish a policy that defines how often you review and update your risk management plan. Many organizations review their plans at least once a year, but you may need to do it more often if threats or business conditions change.

You should update your supply chain risk management plan when you see changes in threats, organizational structure, or environmental factors. Regular reviews help you identify gaps and weaknesses in your current process. You can then adjust your strategies to address new risks and improve your response.

You can involve stakeholders from different departments in the review process. This approach gives you a broader perspective and helps you find better solutions. You can also use feedback from past incidents to improve your risk management strategies. By making continuous improvements, you keep your supply chain strong and ready for future challenges.

Note: Regular reviews and updates help you stay ahead of risks and maintain a resilient supply chain.

You face many types of supply chain risks in your daily operations. Supply chain risk management helps you identify and address these threats before they disrupt your business. Understanding the main risks allows you to build operational resilience and protect your organization from costly interruptions.

Operational risks can stop your supply chain from running smoothly. You might see disruptions from raw material shortages, equipment failures, or labor shortages. For example, during the COVID-19 pandemic, meatpacking plants lost 25% of their production capacity because of worker absenteeism. If you cannot meet delivery targets, your company could lose millions in revenue and damage its reputation.

You need to watch for these common operational risks:

| Operational Risk | Impact on Supply Chain |

|---|---|

| Raw material shortages | Delays production, increases costs |

| Worker absenteeism | Reduces output, affects delivery |

| Equipment breakdowns | Stops production, causes delays |

| Poor supplier performance | Missed deadlines, quality issues |

Supply chain risk management helps you track these risks and respond quickly. You can use real-time monitoring tools to spot problems early and keep your supply chain moving.

Financial risks can have a huge impact on your bottom line. Natural disasters, trade disputes, and cyberattacks can lead to major losses. In 2019, 40 weather disasters each caused more than $1 billion in damage. Trade disputes can cost hundreds of billions. Cybersecurity breaches are common, with most supply chain experts reporting multiple incidents. The pandemic also caused revenue losses for two-thirds of companies, with some losing up to 20% of their income.

You should pay attention to these financial risks:

| Financial Risk | Estimated Cost Impact |

|---|---|

| Natural disasters | $1 billion+ per event |

| Trade disputes | Hundreds of billions |

| Cybersecurity breaches | Multiple incidents per company |

| Pandemic impacts | 6-20% revenue loss |

| Short disruptions | 3-5% of annual profits |

| Long-term disruptions | Up to 50% of annual profits |

Supply chain risk management gives you tools to measure and reduce these risks. You can use insurance, diversify suppliers, and invest in cybersecurity to protect your finances.

Environmental risks are becoming more serious for supply chains. Climate-related disasters, such as hurricanes and floods, can damage factories and delay shipments. In 2023, climate disasters caused over $250 billion in global economic losses. By 2026, environmental risks could cost supply chains $120 billion. If climate disruption continues, global supply chains could lose up to $25 trillion by mid-century.

You need to prepare for these environmental risks:

Supply chain risk management helps you build strategies to handle these risks. You can use data analytics to predict weather events and adjust your operations. By planning ahead, you keep your supply chain strong and ready for future challenges.

Tip: Addressing all types of supply chain risks helps you maintain operational resilience and stay competitive.

You face geopolitical risks every time you manage a global supply chain. These risks can disrupt your operations and force you to adapt quickly. You need to understand how different events and policies affect your supply chain. Geopolitical risks often arise from sudden changes in government, conflict, or international relations. You must stay alert to these risks because they can impact trade routes, supplier reliability, and market access.

Here are some of the most significant geopolitical risks affecting supply chains today:

You should monitor these risks closely. You can use supply chain risk management tools to track changes and respond quickly. By staying informed, you reduce the impact of geopolitical risks on your business.

Tip: Build flexibility into your supply chain to handle sudden changes caused by geopolitical risks.

You encounter cybersecurity risks every day in your supply chain network. These risks have grown rapidly as more companies rely on digital platforms and third-party vendors. Cybersecurity risks can lead to data breaches, loss of sensitive information, and disruption of operations. You need to protect your supply chain from these risks by using strong security measures.

Recent data shows how common cybersecurity risks have become:

| Statistic Description | Value |

|---|---|

| Third-party breaches increase | 30% of breaches involve third-party (up from 15%) |

| Malicious packages in open source software | 512,847 malicious packages logged (156% increase year over year) |

| Growth of malicious threats in repositories | 1,300% increase from 2020 to 2023 |

| Organizations experiencing supply chain attacks | More than 75% in the last year |

You must pay attention to these risks because attackers often target weak links in your supply chain. You can reduce risks by vetting suppliers, updating software, and training employees. You should also use monitoring tools to detect threats early.

FineReport helps you manage cybersecurity risks by providing secure data integration and real-time monitoring. You can use FineReport’s dashboards to track incidents and analyze risk indicators. This approach keeps your supply chain safe and resilient against digital threats.

You need to map and prioritize risks to strengthen your supply chain risk management process. Start by collecting data about your suppliers, part numbers, and spending. You should identify key supplier relationships, including Tier 2 and Tier 3 suppliers. Mapping out transportation routes helps you spot vulnerabilities. Create a supplier risk index by assigning weighted scores to each supplier based on specific concerns. Analyze these risks and develop recommendations to address them.

| Key Steps to Mapping a Supply Chain | Description |

|---|---|

| Gather data | Select key supply chains to map, collect supplier data, part numbers, and spend. |

| Identify key supplier relationships | Understand your suppliers’ suppliers (Tier 2 and 3 suppliers). |

| Map | Identify routings and transportation modes to reveal risks. |

| Create supplier risk index | Develop a weighted risk score for each supplier based on specific concerns. |

| Analyze and act | Brainstorm potential risks and develop recommendations to mitigate them. |

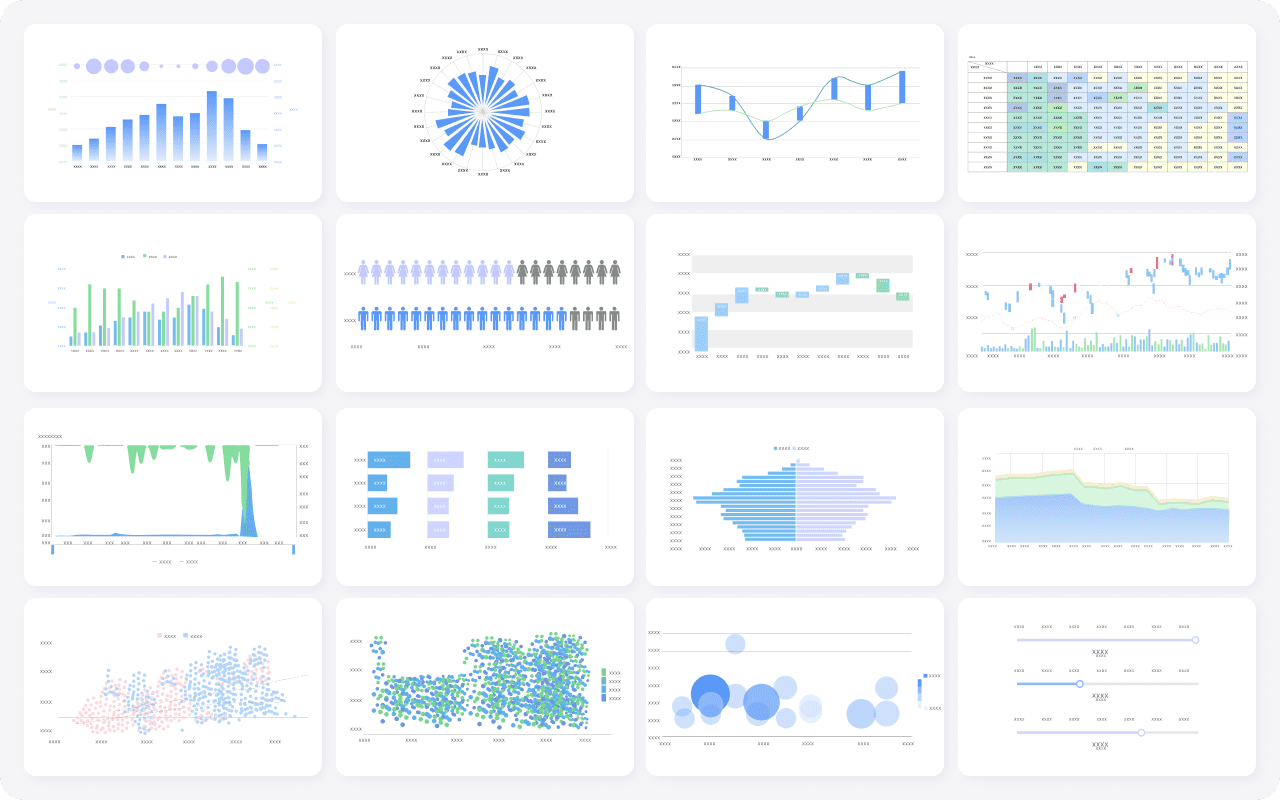

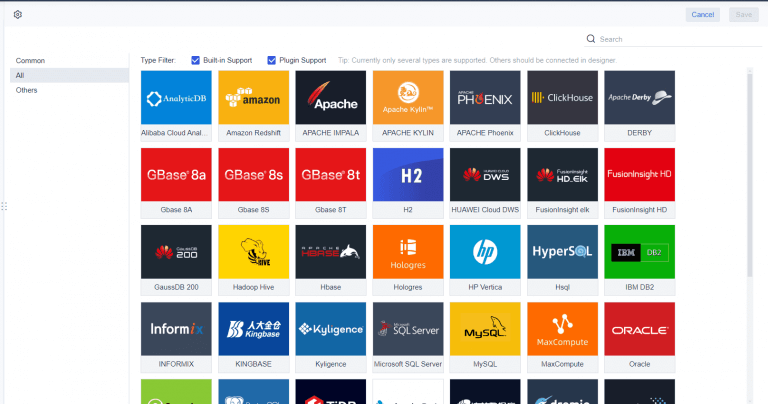

Supply chain risk management software makes this process easier. You can use these tools to accelerate risk identification, improve mitigation, and simplify monitoring. The best software integrates data from different sources, provides real-time analytics, and visualizes complex information through interactive dashboards.

Supplier diversification reduces your exposure to disruptions. You should work with multiple suppliers in different regions. This strategy protects you from geopolitical instability and natural disasters. A recent study found that 81% of manufacturers plan to use geographically diverse suppliers. Companies with regional diversification experience fewer supply chain disruptions than those relying on a single region.

Supply chain risk management software helps you segment suppliers and identify over-reliance on any single source. Many organizations now use dual-sourcing strategies, with 73% reporting progress in this area. You can track supplier performance and adjust your sourcing plans quickly using these digital tools.

Scenario planning prepares you for unexpected events. You need to identify potential scenarios that could impact your supply chain. Assess the possible effects on inventory, delivery, customer satisfaction, and costs. Develop strategies such as alternative suppliers and inventory adjustments. Regularly review and update your plans to adapt to changing risks.

Supply chain risk management software supports scenario planning by modeling different outcomes and providing actionable insights. You can use these platforms to engage key resources, analyze impacts, and create mitigation strategies. FineReport offers advanced visualization and real-time analytics, helping you build robust scenario plans and respond quickly to disruptions.

You need advanced technology to strengthen your supply chain risk management process. Digital tools give you the power to track risks, analyze data, and make informed decisions quickly. FineReport stands out as a solution that brings clarity and control to your supply chain risk management efforts.

FineReport helps you visualize every stage of your supply chain. You can see real-time updates and track logistics from end to end. This visibility lets you spot risks early and respond before they disrupt your operations. FineReport’s dashboards consolidate data from multiple sources, making analysis easier and more accurate. You can use low-code features to integrate data across departments, breaking down silos and improving collaboration.

The table below shows how FineReport’s technology supports supply chain risk management:

| Feature | Benefit |

|---|---|

| End-to-end visibility | Allows tracking of every logistics stage visually, enhancing risk awareness. |

| Real-time insights | Provides immediate data updates, facilitating timely decision-making. |

| Comprehensive data visualization | Consolidates data from multiple sources into a single dashboard for easier analysis. |

| Low-code functionality | Simplifies data integration, reducing silos and improving collaboration across departments. |

| Risk alerts | Uses AI to forecast trends and provide actionable recommendations based on real-time data. |

You can set up risk alerts that use AI to forecast trends and recommend actions. This proactive approach helps you stay ahead of potential disruptions. FineReport’s low-code platform makes it easy for you to customize reports and dashboards, so you get the information you need without relying on IT specialists. By using FineReport, you improve your supply chain risk management and make smarter decisions faster.

You need strong collaboration and clear communication to manage supply chain risk effectively. Working with partners and suppliers helps you identify risks early and develop better solutions. Joint efforts allow you to assess risks in depth and create strategies tailored to your needs.

To build a successful supply chain risk management partnership, follow these steps:

You strengthen your supply chain risk management process when you collaborate and communicate effectively. This approach helps you build resilience and adapt to changing conditions.

A strong supply chain risk management policy gives you a clear framework for protecting your business. You need to set guidelines that help everyone understand how to identify, assess, and respond to risks. This policy supports your efforts to keep operations running smoothly, even when challenges arise.

You start by defining your risk tolerance. This means deciding how much risk you can accept without harming your business, finances, or reputation. You do not need to eliminate every risk. Instead, you focus on keeping risks at levels that allow you to operate safely. You should identify both internal and external risks, then assess how likely they are to disrupt your supply chain. Your supply chain risk management policy should include objectives that improve resilience, ensure business continuity, and give you a competitive advantage. When you set clear goals, you help your team stay focused on what matters most.

Your supply chain risk management policy must outline who does what. Assign clear roles to team members so everyone knows their responsibilities. You need people to handle risk identification, assessment, mitigation, and monitoring. Compliance, ethical sourcing, and environmental considerations also require attention. When you define responsibilities, you make sure that each part of the policy gets the focus it needs. Use technology to support these roles. Real-time data and predictive analytics help your team respond quickly to new risks.

You need to communicate your supply chain risk management policy clearly to all stakeholders. Start by engaging stakeholders through meetings or surveys. Provide actionable plans with specific steps and timelines. Know your audience and tailor messages to different groups. Regular updates keep everyone informed about new risks and changes to mitigation strategies.

| Method | Description |

|---|---|

| Engage Stakeholders | Seek input and address concerns to foster collaboration. |

| Provide Actionable Plans | Outline steps, responsibilities, and timelines for managing risks. |

| Know Your Audience | Tailor messages for different stakeholder groups. |

| Regular Updates | Keep everyone informed about evolving risks and mitigation measures. |

FineReport supports your supply chain risk management policy by providing real-time data, interactive dashboards, and predictive analytics. You can use these tools to improve communication, monitor risks, and make informed decisions.

You need to make risk management part of your daily supply chain activities. Many organizations face challenges when they try to do this. You must deal with complex supplier relationships, changing regulations, and the need for ongoing risk monitoring. The table below shows common challenges you may encounter:

| Challenge | Description |

|---|---|

| Need for a formal supply chain risk management program | You require a structured approach to manage risks effectively. |

| Complexity of third-party relationships | Managing risks with many suppliers and partners adds layers of difficulty. |

| Compliance with evolving regulations | You must keep up with new rules to avoid penalties and stay compliant. |

| Continuous monitoring and assessment of risks | You need to evaluate risks regularly to adapt to new threats and maintain supply chain integrity. |

You should set up systems that allow you to monitor risks in real time. Regulations change often, so you must stay updated to avoid non-compliance issues. When you use dashboards and alerts, you can respond quickly to new risks and keep your supply chain running smoothly.

You build a strong supply chain by encouraging everyone to recognize and address risks. Training helps your team spot risks early and take action before problems grow. When you reward proactive behavior, you create a culture that values prevention over reaction. You should also recognize suppliers who share information and show resilience. This approach extends your risk-aware culture throughout your supply chain.

You can conduct joint risk assessments with key suppliers, set up standardized protocols, and share best practices across your industry. These steps help you respond to risks quickly and effectively.

You improve your supply chain risk management by using data to guide your decisions. You should assess performance trends and monitor key performance indicators for risks. Analyzing supplier performance helps you detect inconsistencies and forecast disruptions. You can anticipate demand changes and spot inventory risks before they affect your business.

FineReport supports your efforts by providing real-time dashboards, automated alerts, and advanced analytics. You can visualize risks, monitor supply chain performance, and make data-driven decisions that keep your operations resilient.

You need a robust supply chain risk management process to protect your business from disruptions and build long-term success. When you use a structured supply chain risk management process, you increase resilience at every stage. This process helps you identify risks, assess threats, and act quickly. You gain supply chain resilience by making informed decisions and preparing for challenges. A strong supply chain risk management process gives you the ability to withstand and recover from disruptions. You minimize operational impacts and ensure continuity of supply. You also improve supply chain resilience by using real-time data and clear policies. When you focus on resilience, you support business continuity and gain a strategic advantage. FineReport helps you strengthen your supply chain risk management process and achieve greater supply chain resilience.

Supply Chain Risk Explained and Why it Matters Now

What is Supply Chain Visibility and Why Does It Matter

Supply Chain Analytics Explained and Its Importance

What is Predictive Analytics in Supply Chain Management

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

9 Best Supply Chain Tools for Smarter Management in 2026

Find the best supply chain tools for 2025 to boost efficiency, gain real-time insights, and achieve smarter management for your business.

Lewis

Dec 18, 2025

Top 10 Supply Chain Tracking Software for 2026

Compare the top supply chain tracking software for 2026 to boost visibility, automate workflows, and leverage AI analytics for smarter decisions.

Lewis

Dec 18, 2025

Top 10 Supply Chain Management Software for Small Businesses

See the top 10 supply chain management software comparison for small businesses in 2026. Compare features, pricing, and scalability to find your best fit.

Lewis

Dec 18, 2025