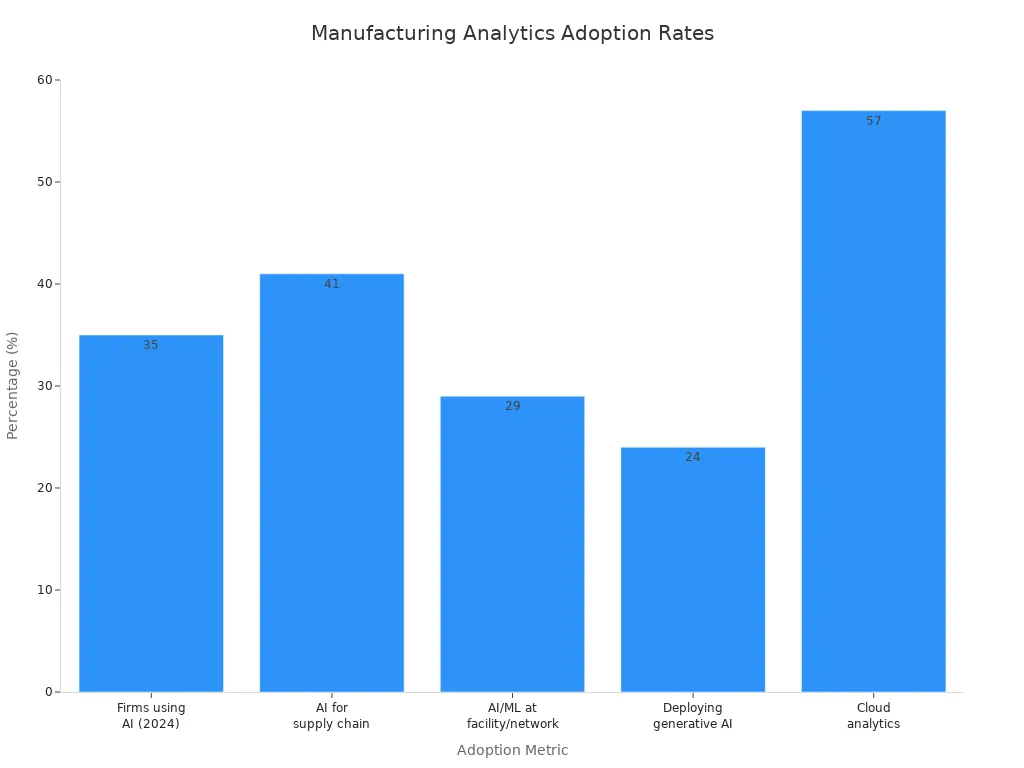

Manufacturing analytics is the use of operations and events data and technologies in the manufacturing industry to ensure quality, increase performance and yield, reduce costs, and optimize supply chains. Manufacturing analytics uses advanced tools to turn factory data into insights that drive better decisions. Many manufacturers now rely on analytics for competitive advantage. Across the globe, 57% of manufacturers use data analytics and cloud computing, while 29% have adopted AI and machine learning at the facility level.

Smart manufacturing and digital transformation continue to reshape the industry. Manufacturers who use analytics see real results. Siemens, for example, increased efficiency by 20% with production line analytics, while Ford saved over €1 million through predictive maintenance. FanRuan and its FineBI platform help manufacturers unlock the full value of data-driven operations.

Manufacturing analytics is the process of collecting, integrating, cleaning, and analyzing data from different sources in a factory. This includes machines, sensors, supply chains, and even customer feedback. Leading industry organizations describe manufacturing analytics as a journey that transforms raw data into actionable insights. These insights help manufacturers improve product quality, optimize production efficiency, reduce costs, and make better decisions.

Manufacturing analytics uses several types of analysis:

The process involves many technologies and steps:

Manufacturing analytics is not just about technology. It also involves best practices, such as starting with small pilot projects, scaling up with a clear plan, aligning analytics with business goals, ensuring data quality, and building a data-driven culture. These steps help manufacturers get the most value from their data and support continuous improvement.

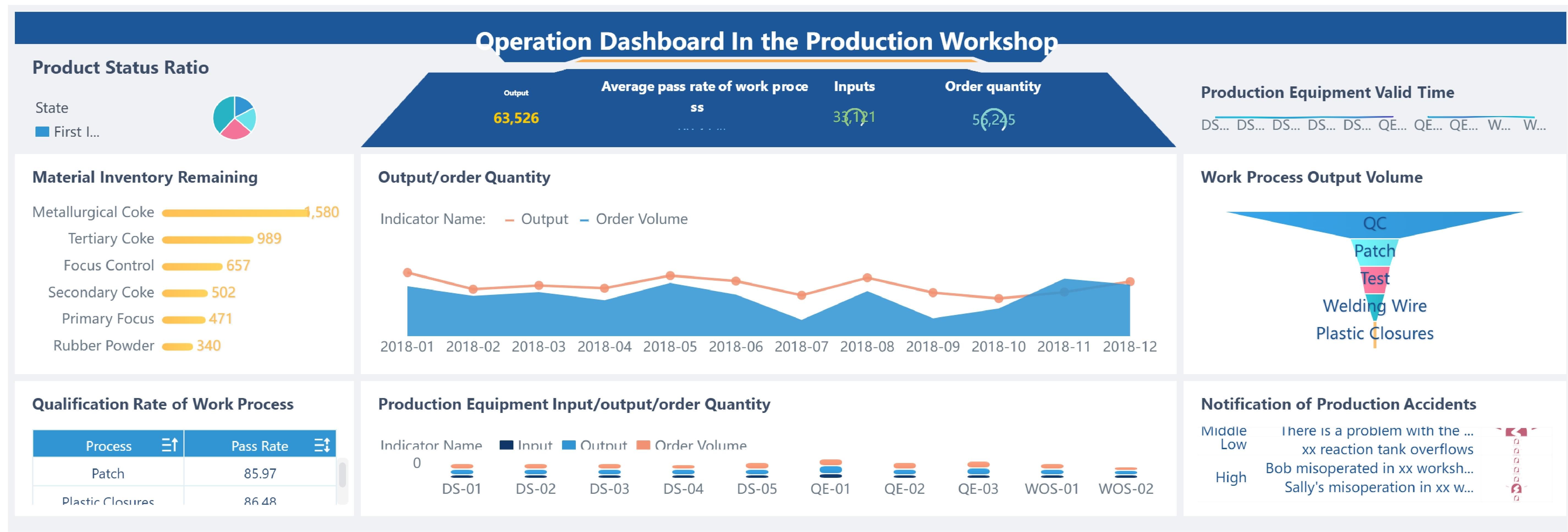

Below is a Manufacturing Management Dashboard by FineBI.

Manufacturing analytics plays a key role in modern manufacturing. It helps manufacturers solve real problems and stay competitive in a fast-changing market. By using analytics, manufacturers can:

Manufacturing analytics supports digital transformation in factories. It enables predictive analytics, quality tracking, and supply chain visibility. Analytics reduces errors and manual work, making operations more efficient. Studies show that data-driven decision-making can improve productivity by up to 20%. Predictive maintenance powered by AI can reduce downtime by 15–30% and extend asset life by 20%.

Many leading manufacturers have seen real benefits:

Rolls-Royce uses IoT-driven digital twins to predict component wear, extending service intervals by over 70%.

Schneider Electric reduces facility emissions by about one-third with energy-management analytics.

Ford cuts equipment downtime by 25% using IoT sensors and AI.

Siemens achieves a first-pass yield of 99.99885% with real-time quality analytics.

GE lowers unplanned downtime by up to 20% and reduces power use with plantwide data lakes.

Manufacturing analytics empowers manufacturers to make data-driven decisions at every level. It turns big data analytics into actionable insights, helping factories become smarter, more efficient, and more competitive. As smart manufacturing and Industry 4.0 continue to grow, manufacturing analytics stands as a foundation for innovation and success.

Manufacturing analytics transforms how factories operate by making processes more efficient and reducing costs. Factory teams use analytics to monitor key performance indicators such as machine utilization, production time, scrap rates, and costs. These metrics help identify bottlenecks and improve resource use. When teams see where delays or waste occur, they can act quickly to fix problems.

Factories that use manufacturing analytics often see measurable improvements. For example, a leading automotive manufacturer reduced unplanned downtime by 35%. A food processing plant improved its overall equipment effectiveness to 92%. Predictive analytics help factories schedule maintenance before equipment fails, which saves money and keeps production running smoothly. One chemical manufacturer saved $18 million in a year by using predictive maintenance.

| Metric Description | Value | Impact Description |

|---|---|---|

| Reduction in unplanned downtime | 35% | For a leading automotive manufacturer |

| Improvement in overall equipment effectiveness (OEE) | 92% | For a food processing plant |

| Annual cost savings | $18 million | For a chemical manufacturer via predictive maintenance |

| Procurement cost reduction | 15% | Achieved through advanced supply chain analytics |

| Resource waste reduction | 10-20% | Achieved through energy analytics |

Manufacturing analytics also helps with production optimization. Teams use real-time data to spot trends and adjust production schedules. This reduces overstocking and lowers inventory costs. Companies like Continental Tires use analytics to eliminate bottlenecks and optimize the use of materials, staff, and machines across multiple plants. FleetPride uses analytics to improve warehouse locations and delivery routes, which reduces labor costs and increases revenue.

Manufacturers gain cost savings by increasing visibility into production costs. Real-time data collection allows teams to make informed decisions about maintenance, production timing, and inventory control. Many CEOs now invest in AI and predictive analytics because these tools deliver a strong return on investment.

Tip: Real-time data capture enables teams to eliminate errors and minimize waste before they become costly problems.

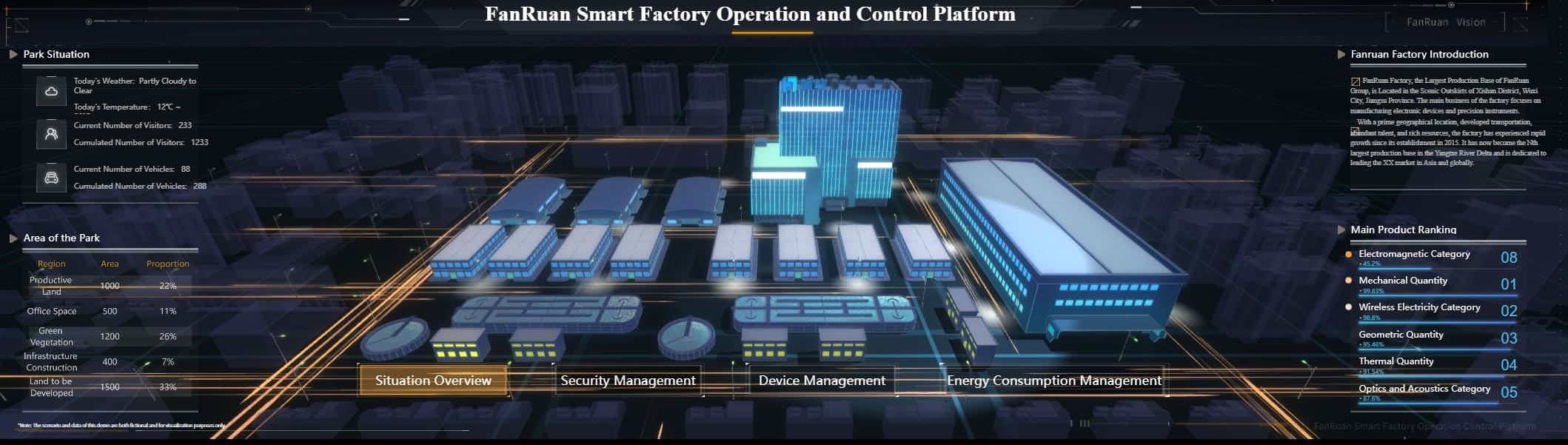

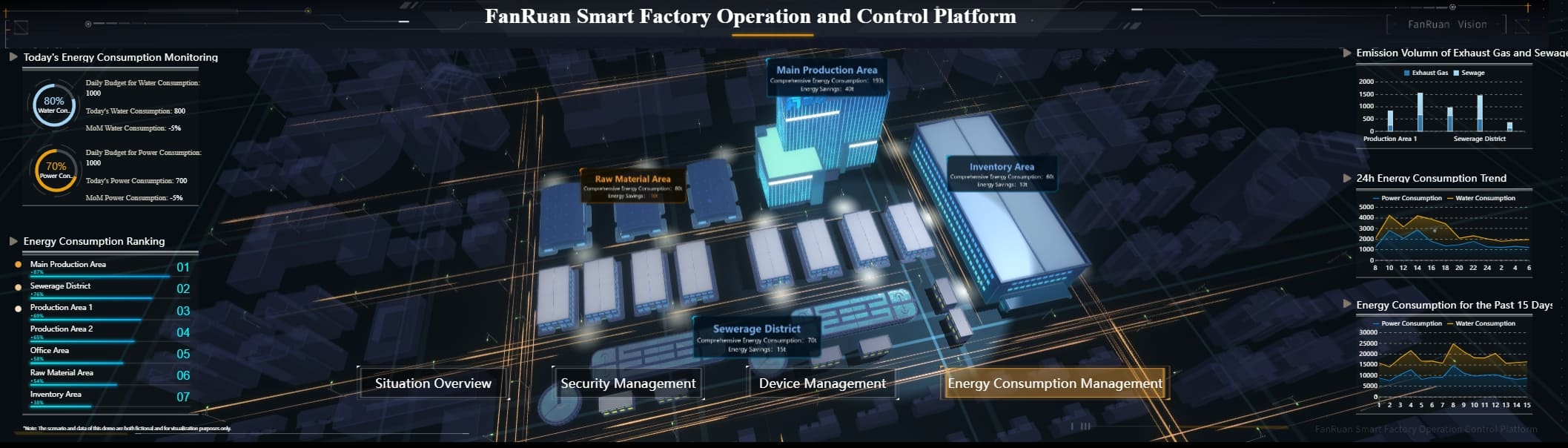

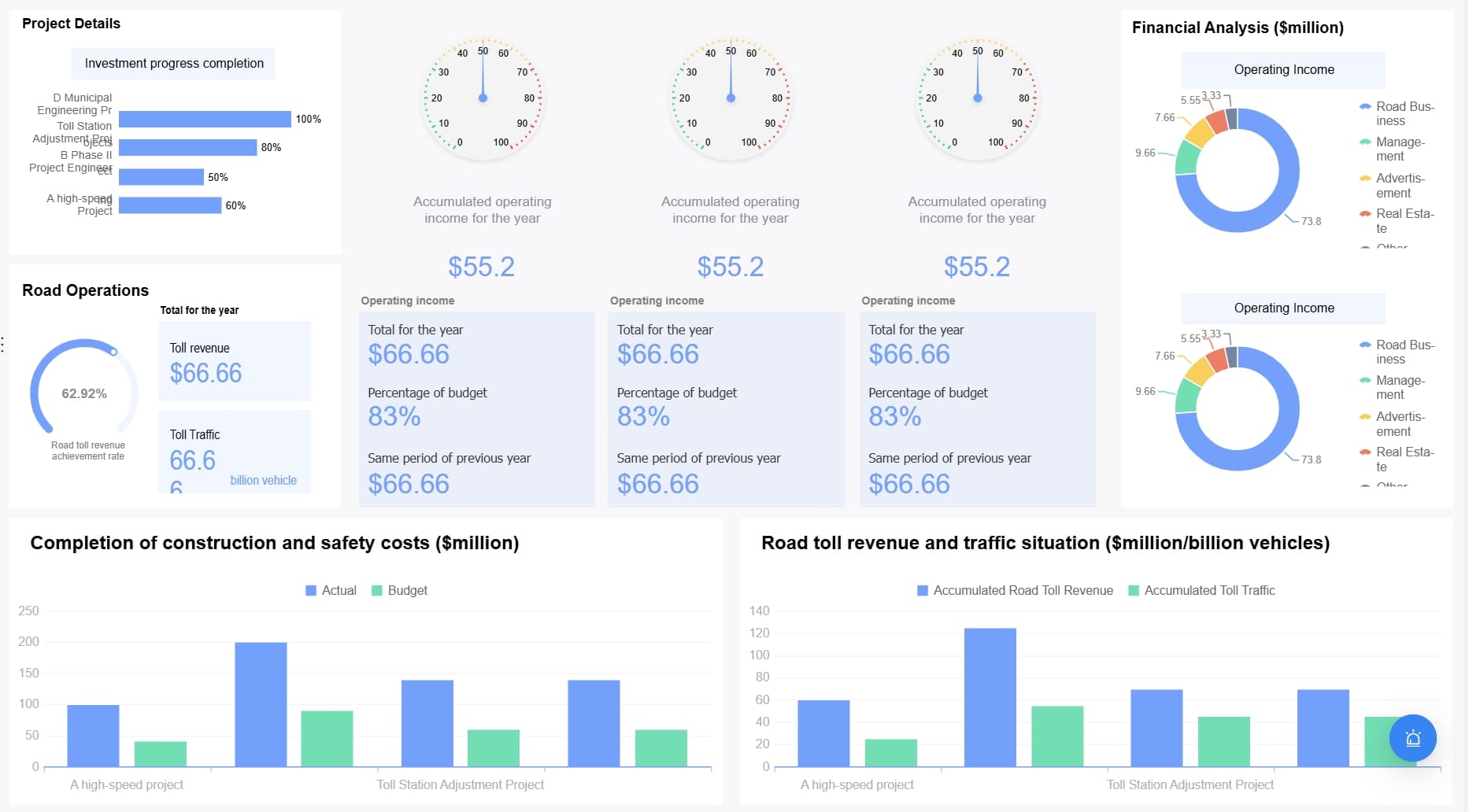

Below is a real-time factory facilities control dashboard by FineBI.

Manufacturing analytics plays a vital role in improving product quality. Factories use real-time quality monitoring to detect and predict defects as soon as they happen. Predictive algorithms analyze data from IoT sensors, ERP, and MES systems to find deviations in the production process. When a problem appears, analytics can trace it back to a specific machine or step, making it easier to fix.

This proactive approach reduces rework costs and ensures consistent product quality. Machine learning algorithms help teams perform root cause analysis and take targeted actions. By scheduling maintenance during non-peak hours, factories minimize disruptions and keep quality high. Customers receive better products, and factories build stronger reputations.

Factory managers rely on real-time insights to make fast, data-driven decisions. Live dashboards and alerts show the current status of production, quality, and equipment. Managers can respond quickly to downtime, adjust processes, and prevent defects. Real-time data visualization helps teams track KPIs and spot trends without using complex tools.

Some of the most valuable real-time insights for managers include:

Process optimization becomes easier when teams have access to real-time data. They can test changes, see results immediately, and learn what works best. This cycle of continuous improvement helps factories stay competitive in the world of smart manufacturing.

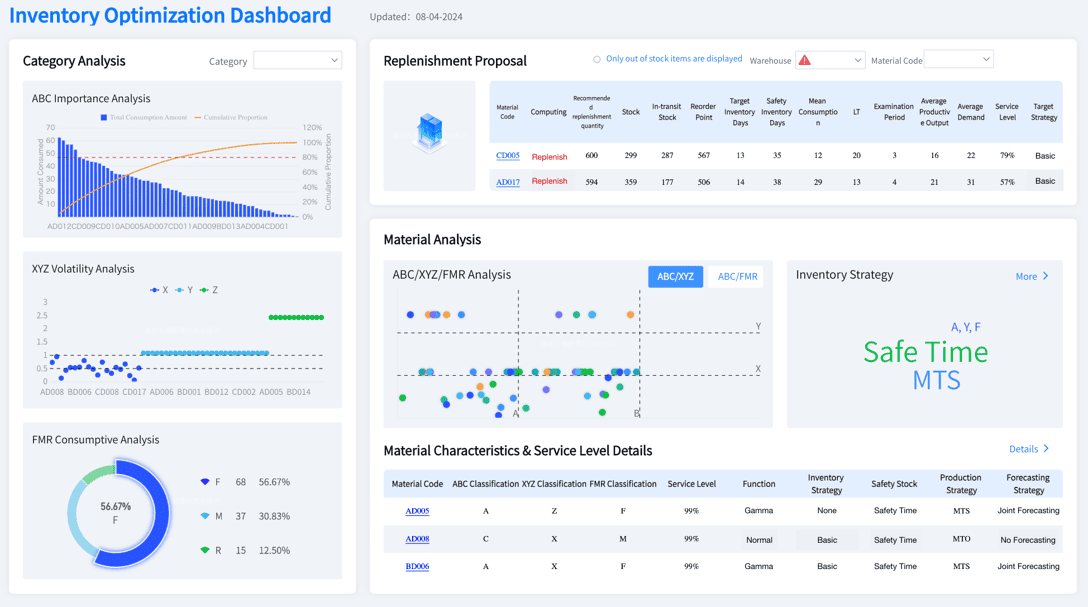

Below is a inventory optimization dashboard created by FineBI.

FanRuan and its FineBI platform offer unique advantages for manufacturing software solutions. FineBI provides self-service analytics, allowing users to explore and understand data without needing advanced technical skills. The platform connects to over 30 big data platforms, SQL sources, Excel, and multi-dimensional databases. This broad connectivity ensures that all relevant manufacturing data is available for analysis.

FineBI supports advanced data modeling, making it easy to manage complex data relationships. Users can clean and edit data visually with a low-code ETL module. Multi-dimensional analysis lets teams drill down into details, adjust levels, and use different calculation methods. The platform offers a wide range of visualization options, so users can create dashboards that fit their needs.

Manufacturing software like FineBI stands out with enterprise-level features. High concurrency and availability allow thousands of users to access data at the same time. The high-performance computing engine handles large datasets, which is essential for modern manufacturing. Role-based permission management keeps data secure, while adaptive dashboards work on any device, including mobile apps.

FineBI also supports data collaboration and sharing. Teams can work together on dashboards, share insights after admin review, and manage data in organized folders. Dual data storage modules improve reliability and reduce duplication. These features help manufacturing teams analyze, visualize, and share insights efficiently, supporting smart manufacturing and continuous improvement.

Manufacturing analytics begins with collecting data from many sources across the factory. These sources include manufacturing equipment, automation systems, and enterprise management systems like MES and ERP. External data, such as environmental conditions, customer feedback, and supply chain information, also play a role. Sensors, wireless devices, and software logs capture real-time data throughout the manufacturing process.

Data integration platforms, such as FineDataLink, help unify this information. They use methods like ETL and ELT to extract, transform, and load data from different systems. Data quality checks, cleansing, and validation ensure accuracy and consistency. This unified approach supports applications like predictive maintenance, yield management, and product re-engineering.

A strong data foundation allows manufacturing software to provide a complete view of operations. Real-time data integration enables teams to monitor production, track inventory, and respond quickly to changes.

Once data is integrated, analytics tools process and analyze it to generate actionable insights. Descriptive analytics summarize past operations, while predictive analytics use machine learning to forecast equipment failures or demand changes. Prescriptive analytics recommend the best actions to optimize the manufacturing process.

Real-time dashboards display key performance indicators, such as equipment efficiency and labor productivity. These dashboards centralize monitoring, making it easier for managers to spot issues and make informed decisions. Automation reduces manual errors and supports dynamic adjustments on the factory floor.

Choosing a technology partner with proven expertise, flexibility, and a commitment to quality—such as FanRuan and FineBI—ensures every investment in manufacturing analytics supports ongoing profitability and future growth. Businesses who act now secure the benefits of innovation, resilience, and market leadership.

Explore FineBI to build your digital factory!

Data Analytics Meaning Explained for Modern Businesses

What is Manufacturing Engineering and Why is it Essential in Malaysia

Use Diagnostic Analytics for Smarter Business Decisions in Malaysia

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

9 Best Supply Chain Tools for Smarter Management in 2026

Find the best supply chain tools for 2025 to boost efficiency, gain real-time insights, and achieve smarter management for your business.

Lewis

Dec 18, 2025

Top 10 Supply Chain Tracking Software for 2026

Compare the top supply chain tracking software for 2026 to boost visibility, automate workflows, and leverage AI analytics for smarter decisions.

Lewis

Dec 18, 2025

Top 10 Supply Chain Management Software for Small Businesses

See the top 10 supply chain management software comparison for small businesses in 2026. Compare features, pricing, and scalability to find your best fit.

Lewis

Dec 18, 2025