Quality 4.0 brings digital transformation to quality management, helping you understand and improve quality with advanced technology. Today, only 16% of organizations have started integrating digital tools for quality 4.0, while most have yet to make plans. Companies that embrace digital scorecards and connected goal-setting see higher performance and better customer satisfaction. Leadership, people, and technology drive success in quality 4.0. FineBI supports your journey by making data analysis and visualization easier for effective quality management.

Quality 4.0 represents a major shift in how you approach quality management. This concept combines traditional quality principles with advanced digital technologies. You see the influence of Industry 4.0, which brings automation, connectivity, and data-driven decision-making into every aspect of quality. Quality 4.0 programs help you move beyond manual processes and reactive controls. You gain the ability to predict and prevent quality issues before they impact your business.

Quality 4.0 introduces several key features that set it apart from earlier quality management approaches. You benefit from system integration, decentralization, interoperability, virtualization, and real-time capacity. These features allow you to connect machines, people, and processes seamlessly. You can access data from multiple sources and analyze it instantly. Quality 4.0 leaders focus on integrating advanced digital technologies such as the Internet of Things (IoT), Cyber-Physical Systems, and Big Data with Total Quality Management (TQM) principles. This integration drives business excellence and efficiency.

Quality 4.0 emphasizes:

You see the difference between quality 4.0 and previous paradigms in both process and outcomes. The table below highlights these distinctions:

| Aspect | Quality 4.0 | Previous Paradigms |

|---|---|---|

| Technology Integration | Utilizes IoT, AI, big data, and cloud computing | Relied on manual processes |

| Approach | Data-driven and automated | Reactive quality control methods |

| Focus | Predicting and preventing quality issues | Addressing issues post-factum |

| Outcomes | Improved operational efficiency and data usage | Limited efficiency and data utilization |

You notice that quality 4.0 relies on data and automation, while older systems depend on manual intervention. This shift leads to better efficiency and proactive quality management.

The digital transformation process in quality 4.0 changes how you manage quality across your organization. You use technologies like AI, machine learning, IIoT, robotics, blockchain, big data analytics, and cloud computing. These tools help you automate tasks, manage data, and optimize manufacturing. You also see the rise of digital threads, computer-aided manufacturing, manufacturing execution systems, and digital twins. These innovations support model-based work instructions and real-time monitoring.

You benefit from AI and automation, which recognize patterns and optimize processes. Quality 4.0 programs give you access to real-time data and system integration. You use AI and automation to improve process optimization, while human expertise remains essential for strategic decisions.

You see how the combination of AI and IoT allows for real-time data collection. This capability enhances decision-making in quality management. AI algorithms analyze data from IoT devices, identify patterns, and predict outcomes. You shift from reactive to proactive quality management. IoT enables predictive maintenance by monitoring equipment in real time and predicting failures before they occur. This reduces downtime and improves productivity, ensuring consistent product quality.

Quality 4.0 integrates AI, Big Data, IoT, and cloud computing to enhance traditional quality processes. You embed smart, real-time insights into every stage of production and service lifecycle. The digital transformation process in quality management leads to significant improvements in efficiency. Studies show that digital transformation reduces future external transaction costs, enhances market position, and improves financial performance. Companies report increased supply chain efficiency, especially those with lower environmental performance, smaller size, and lower quality of information disclosure.

| Evidence Type | Description |

|---|---|

| Study Period | 2007 to 2022 |

| Sample Size | A-share listed companies in China |

| Key Findings | Significant positive impact of digital transformation on supply chain efficiency, especially in companies with lower environmental performance, smaller size, and lower quality of information disclosure. |

| Economic Impact | Reduces future external transaction costs, enhancing market position and financial performance. |

Surveys show that organizations adopting quality 4.0 experience many benefits. You see increased efficiency (60%), improved quality and compliance (56.5%), time savings (>50%), cost savings (>50%), productivity increases (38.5%), complexity reduction (29.7%), risk mitigation (>20%), business transformation (>20%), and sustainability improvements (>14%).

| Benefit | Percentage of Respondents |

|---|---|

| Increased Efficiency | 60% |

| Quality and Compliance | 56.5% |

| Time Savings | >50% |

| Cost Savings | >50% |

| Productivity Increase | 38.5% |

| Complexity Reduction | 29.7% |

| Risk Mitigation | >20% |

| Business Transformation | >20% |

| Sustainability | >14% |

Quality 4.0 gives you the tools to transform your quality management approach. You move from manual, reactive methods to automated, predictive, and data-driven processes. You achieve higher efficiency, better compliance, and greater business value.

Quality 4.0 builds on foundational principles that drive excellence in modern organizations. You see how leadership, people, data, and technology interact to shape quality outcomes. These elements work together to create a strong framework for quality 4.0 programs. When you understand these core concepts, you can lead successful digital transformation and achieve higher standards in quality management systems.

You play a vital role in guiding your organization through quality 4.0 transformation. Leadership sets the vision and roadmap for quality 4.0 programs. You align quality objectives with corporate strategy and foster a culture of accountability. Top management support encourages positive attitudes toward new systems and practices. When you commit to quality 4.0, you drive adoption and success.

You see a strong link between leadership commitment and successful outcomes. Studies show that top management commitment has a significant relationship with lean practices (correlation coefficient of 0.82) and the adoption of Industry 4.0 technologies (correlation coefficient of 0.78). The strategic direction of your organization depends on the values and commitments of top management.

| Aspect | Description |

|---|---|

| Executive Buy-in | Essential for the success of quality 4.0 initiatives; leaders must align quality objectives with corporate strategy. |

| Culture of Quality | A strong quality culture empowers employees and enhances overall quality through modern tools and practices. |

| Technology Integration | Aligning quality 4.0 initiatives with digital transformation strategies enhances connectivity and collaboration across the organization. |

You drive quality 4.0 by empowering people and building a culture of quality. Quality professionals help navigate digital transformation and maintain excellence. You encourage collaboration and knowledge sharing, which supports continuous improvement. When you align your vision and goals with technological change, you make adoption easier.

| Aspect | Description |

|---|---|

| Vision and Goals | Aligning organizational vision and goals with technological change is crucial for adoption. |

| Organizational Structure | An organic structure fosters innovation and employee engagement, enhancing technology adoption. |

| Knowledge Sharing | Implementing norms of collaboration and knowledge sharing supports continuous technology use. |

You engage employees in the change management process. When teams participate from the beginning, they identify inefficiencies and suggest improvements. This involvement increases productivity and builds commitment. You use effective communication strategies to address concerns and empower employees. Continuous learning becomes part of daily operations.

You monitor productivity metrics to give employees a clear view of their performance. You use these metrics for feedback and action plans. Gamification creates scoring systems and rewards, motivating teams to improve quality.

You build a culture that supports continuous improvement. This culture integrates quality management throughout the product lifecycle, from design to post-market support. Quality lifecycle management helps you evolve with feedback and learning, making your supply chain more agile and responsive.

You rely on data and technology to support quality 4.0 initiatives. Machine learning, artificial intelligence, mobile technology, augmented reality, virtual reality, cloud technologies, connected devices, big data, data lakes, social media, and blockchain all play important roles. You use these tools to enhance operational efficiency and quality control.

You see how integrating these technologies boosts automation and improves quality control. Industry 4.0 technologies, such as robotics and IoT, increase economic competitiveness and help you achieve higher standards in quality management systems.

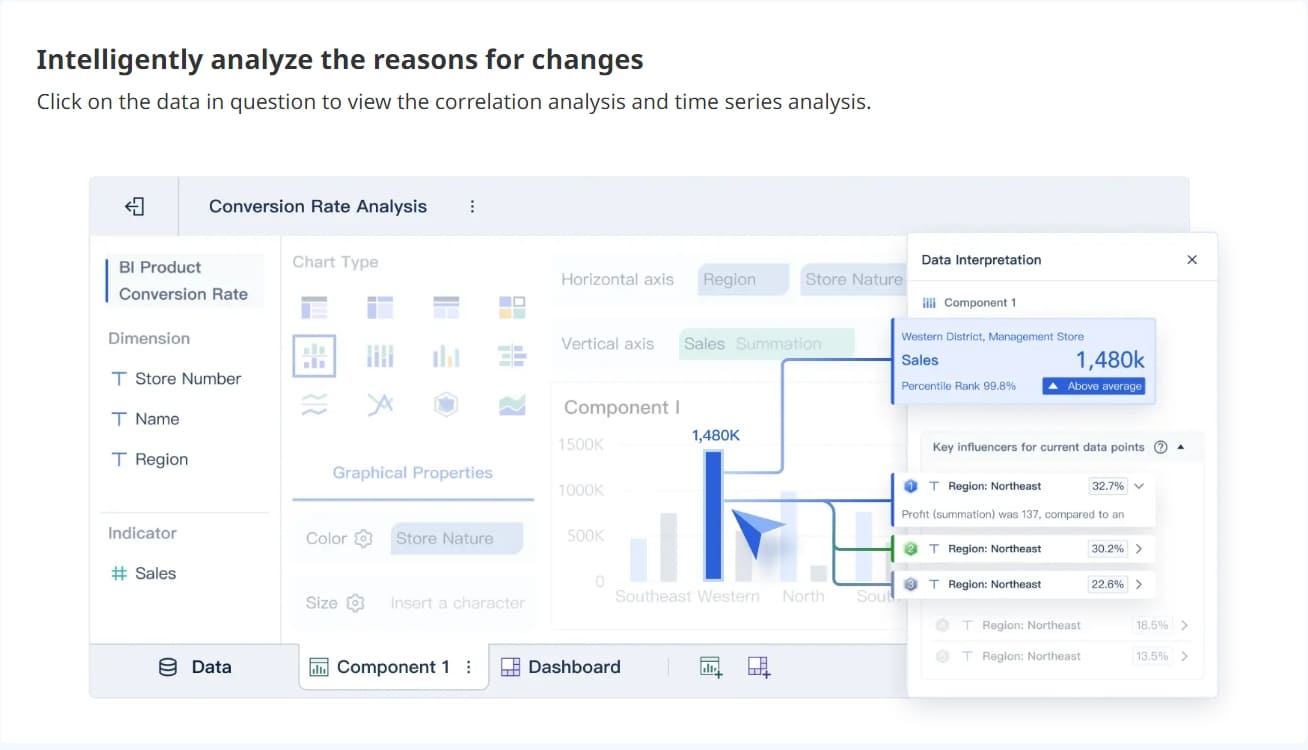

FineBI supports your quality 4.0 journey by providing a comprehensive data analytics platform. You connect to various data sources and integrate information for unified analysis. FineBI enhances data analysis efficiency by over 50%. You perform real-time data analysis without delays after updates, which boosts efficiency by 19%. FineBI empowers you to understand and use your data effectively, leading to better decision-making and improved business performance.

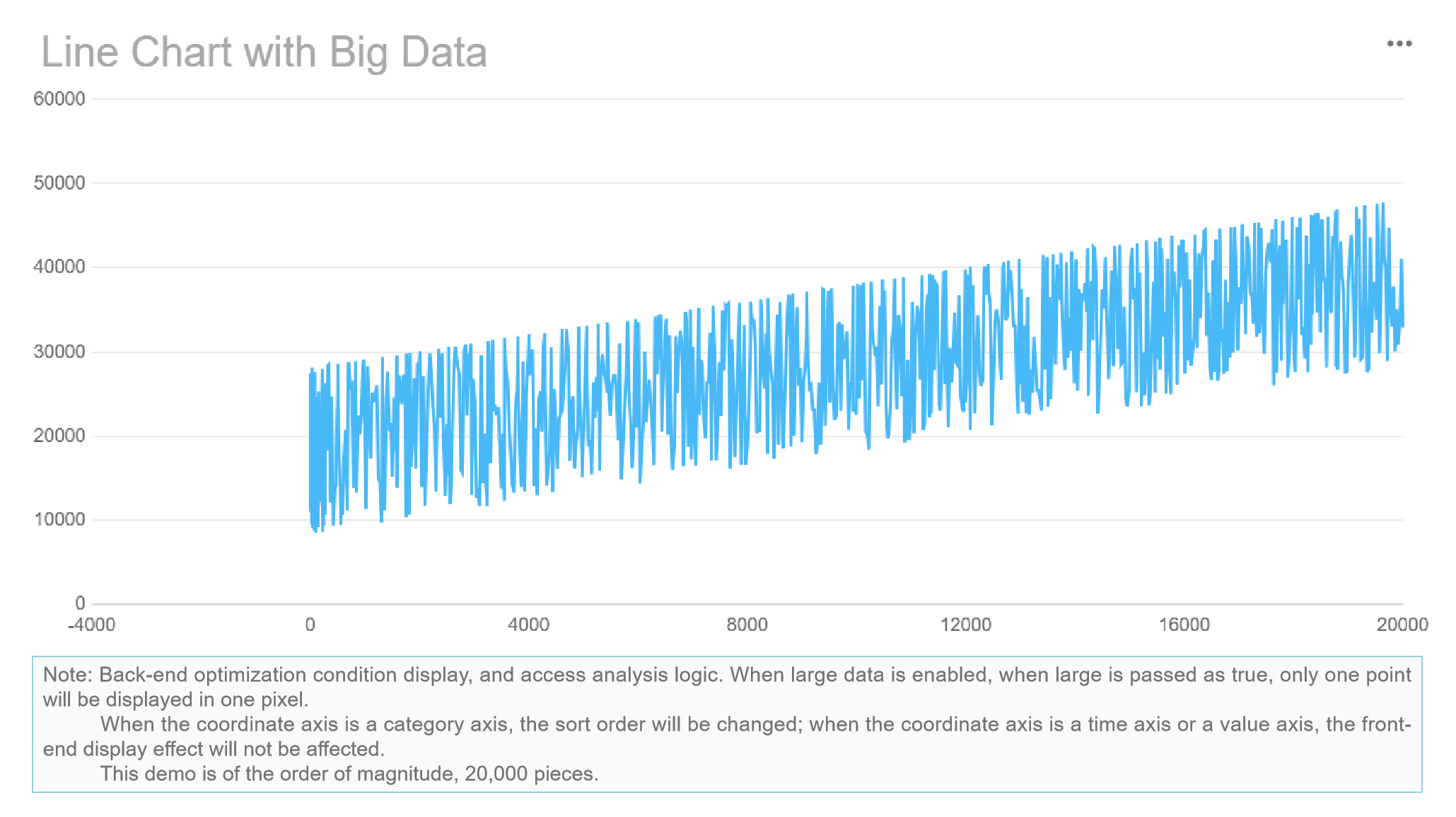

FineBI stands out among business intelligence tools. Its robust analytics and visualization capabilities make it a strong choice for quality 4.0 strategies. You use self-service features and real-time data processing to make quick, data-driven decisions. FineBI’s drag-and-drop interface is easy to use, even for those with minimal technical skills. You access real-time data and respond instantly to changing conditions. FineBI’s high-performance computing engine processes large datasets efficiently, keeping your analytics current and supporting your quality 4.0 goals.

You see how data and technology, combined with leadership and culture, create a powerful foundation for quality 4.0. When you use tools like FineBI, you gain real-time insights, improve collaboration, and drive continuous improvement across your organization.

You can start your quality 4.0 journey by following a clear set of steps. These steps help you integrate digital technologies into your quality management systems and drive continuous improvement. Here is a recommended approach:

You should align these steps with your organization's goals. This approach ensures that quality 4.0 becomes a core part of your continuous improvement programs.

FineBI supports you at every stage. You connect to multiple data sources, schedule updates, and unify your data. You process and clean your data, build datasets, and apply formulas. You visualize your results with drag-and-drop dashboards and share insights securely. FineBI’s governance features help you audit user activity and maintain data quality.

You may face several challenges when adopting quality 4.0. Common issues include workforce skill gaps, cybersecurity concerns, and the integration of legacy systems. High initial costs can also be a barrier, especially for smaller businesses. Cultural resistance and lack of leadership support may slow down your progress.

To overcome these challenges, you need strong change management and leadership support. Training and reskilling help your team adapt to new technologies. Upgrading legacy systems and adopting modern quality management systems make integration easier. Real-time monitoring and analysis tools, like FineBI, allow you to track processes, use predictive analytics, and prevent defects. These tools help you reduce variability and support continuous improvement.

You measure the success of quality 4.0 initiatives using clear metrics. The table below shows common key performance indicators (KPIs):

| KPI | Description |

|---|---|

| First pass yield | Percentage of products made correctly without rework |

| Availability | Proportion of time a system is operational |

| Throughput rate | Rate at which products are produced |

| Downtime | Time a system is not operational |

| OEE (Overall Equipment Effectiveness) | How well a manufacturing operation is utilized |

| Scrap ratio | Ratio of scrap produced to total production |

| Count | Total number of items produced |

| Goal | Target performance level |

| Takt time | Maximum allowable time to produce a product to meet demand |

You also track productivity impact and overhead reduction. Implementing digital quality management systems increases adoption rates and delivers a rapid return on investment. You identify opportunity zones, start with small solutions, and expand based on results. Real-time data helps you measure value and drive continuous improvement.

You gain a competitive edge when you understand and apply quality 4.0. This approach transforms quality management from reactive to predictive, using technologies like IoT and AI. Leadership, people, data, and technology work together to build a culture of continuous improvement. You can start by defining quality 4.0, developing a clear roadmap, and investing in talent and training. Connect your systems and align technology goals with your needs. FineBI helps you integrate data and visualize quality metrics, supporting your journey toward smarter quality management.

How to Do Retention Analysis for Business Success

What is Pareto Chart and How Does it Work

How DuPont Analysis Helps You Understand Your Business

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

9 Best Supply Chain Tools for Smarter Management in 2026

Find the best supply chain tools for 2025 to boost efficiency, gain real-time insights, and achieve smarter management for your business.

Lewis

Dec 18, 2025

Top 10 Supply Chain Tracking Software for 2026

Compare the top supply chain tracking software for 2026 to boost visibility, automate workflows, and leverage AI analytics for smarter decisions.

Lewis

Dec 18, 2025

Top 10 Supply Chain Management Software for Small Businesses

See the top 10 supply chain management software comparison for small businesses in 2026. Compare features, pricing, and scalability to find your best fit.

Lewis

Dec 18, 2025