Green manufacturing uses methods that minimize waste and pollution, slow the depletion of resources, and support eco-friendly manufacturing goals. You see this approach growing fast, with the sustainable manufacturing market expected to double by 2030. Companies now face global competition, customer demands for speed and quality, and stricter regulations. These drivers push a green manufacturing transition, supported by digital tools like FineReport. Such tools streamline data collection, automate reporting, and help you make smarter, more sustainable decisions.

Green manufacturing means you use processes and materials that reduce harm to the environment. Over the past decade, you see a shift toward sustainable practices that focus on minimizing environmental impact and improving resource efficiency. You now find companies adopting eco-friendly materials, such as bamboo, recycled steel, and reclaimed wood. You also notice a growing emphasis on the circular economy, where products are designed for reuse, repair, and recycling.

Green manufacturing is primarily about changing business and manufacturing practices, as well as the mindset of stakeholders, to mitigate the industrial impact on climate change and other environmental concerns.

You integrate new technologies like IoT and AI to streamline resource use and enhance sustainability. You see factories upgrading to high-efficiency machinery and smart energy systems that monitor and optimize energy use. These changes help you lower operational costs and reduce your carbon footprint.

Green manufacturing matters for both your business and the environment. You face increasing scrutiny and penalties for environmental violations, so compliance with regulations is essential. Consumers now prefer products made with sustainable materials and eco-friendly methods. You also benefit from tax incentives and financial assistance when you adopt green manufacturing methods.

| Benefit | Description |

|---|---|

| Employee Motivation | A positive image from green practices can enhance employee morale, making them feel valued. |

| Consumer Demand | Increasingly, consumers prefer products made with sustainable materials and eco-friendly methods. |

| Profitability | Implementing sustainable practices can lead to significant profit increases, estimated at 51%-81%. |

| Tax Benefits | Many governments provide financial assistance for companies adopting green manufacturing methods. |

You help the environment by reducing waste, recycling materials, and using resources more efficiently. You expand the traditional "reduce, reuse, recycle" approach to include repair, refurbish, and rebuild, which leads to longer product lifespans and less hazardous emissions. You also improve efficiency and profitability by adopting sustainable practices.

A lifecycle assessment shows that most opportunities for reducing environmental impacts happen during the product design phase. You can influence sustainability early, which affects both costs and environmental outcomes.

You play a vital role in improving energy efficiency when you adopt green manufacturing practices. Energy efficiency means you use less energy to produce the same amount of goods. This principle helps you lower costs and reduce your environmental impact. You can achieve energy efficiency by investing in energy-efficient equipment, implementing smart manufacturing systems, and optimizing production processes. For example, replacing outdated machinery with modern, energy-saving alternatives can cut your energy costs. Colgate-Palmolive reduced energy usage by 15% on its packaging lines by using innovative sensors and automation.

| Method | Description | Impact |

|---|---|---|

| Energy-efficient equipment | Replace old machinery with efficient models | 10% reduction in global electricity consumption |

| Smart manufacturing | Use automation and data analytics to optimize energy use | 15% reduction in energy usage in specific applications |

| Process optimization | Streamline production and eliminate unnecessary steps | Lower energy consumption and improved productivity |

| Renewable energy | Integrate solar or wind power | Long-term savings and stable energy costs |

| Continuous improvement | Encourage energy-saving ideas and monitor progress | Ongoing improvements in energy efficiency |

You see measurable results when you focus on energy efficiency. Green manufacturing technology innovation decreases energy intensity in both the short and long term. Developed economies experience significant benefits quickly, while developing economies see more impact over time. When you reduce energy use, you support sustainability and improve your bottom line.

Tip: Foster a culture of continuous improvement by encouraging everyone in your organization to share energy-saving ideas and track progress using key performance indicators.

Waste reduction stands as a core principle of green manufacturing. You minimize waste by performing audits, identifying major waste sources, and revamping production processes. You can reduce physical waste volume through lightweighting and process improvements. Many companies use waste exchanges to sell reusable or recyclable materials, turning waste into value. Outsourcing waste management and reusing materials in closed-loop systems also help you achieve waste reduction goals.

| Company Name | Waste Reduction Achieved | Cost Savings |

|---|---|---|

| Canyon Creek Cabinet Company | Reduced hazardous and solid wastes, wastewater discharges, and energy consumption. | $1,189,550/year |

| Custom Print | Reduced chemical inventory by 70% and wasted ink. | $5,000/year and $2,000/month in electricity costs |

| Guardian Automotive | Recycled over 13,000 tons of waste. | $360,000 |

You see that waste reduction not only benefits the environment but also leads to significant cost savings. Green manufacturing encourages you to reuse materials and recycle waste, which supports a circular economy and reduces landfill impact.

Note: Regular audits and process improvements help you identify new opportunities for waste reduction and keep your operations efficient.

Choosing green materials is essential for sustainable manufacturing. You select materials that are recycled, recyclable, or bio-sourced, such as bamboo, cork, or hemp. Eco-friendly insulation, smart materials, and low-carbon emission options also support your green manufacturing goals. You can use materials with low emissions of volatile organic compounds (VOCs) and those that reduce water waste. Self-healing and self-cleaning materials, carbon capture materials, and ecological façade coatings further enhance sustainability.

Green materials help you conserve natural resources and promote a cycle of reuse and recycling. You support biodiversity by choosing sustainable timber from responsibly managed forests. These materials improve energy efficiency, have longer lifespans, and contribute to healthier indoor environments.

Tip: When you choose green materials, you reduce your environmental footprint and create healthier spaces for workers and customers.

Water conservation is a key principle in green manufacturing. You save water by performing routine maintenance, upgrading equipment, and reusing water in your processes. Pretreating and recycling water allows you to use it for different applications, lowering sourcing and treatment costs. Auditing water use and educating employees help you identify and reduce waste.

| Industry Type | Water Reduction Achieved |

|---|---|

| Paper Manufacturing | 5 million gallons per year |

| Food Processing | 40% reduction in water consumption |

| Aerospace Manufacturing | 50% reduction in water usage |

You see significant water savings when you implement these strategies. Installing high-efficiency fixtures, such as low-flow faucets and dual-flush toilets, further reduces water consumption. Green manufacturing encourages you to monitor water use and invest in technologies that support long-term sustainability.

Note: Regular leak detection and equipment upgrades can save thousands of gallons of water each year, supporting both environmental and financial goals.

You build a sustainable supply chain by aligning your company’s goals with eco-friendly practices. You start by establishing clear communication across all levels, making sure everyone understands the sustainability objectives. You conduct ongoing evaluations to adapt to changing risks and priorities. You use planning software to create what-if scenarios, which helps you minimize waste and optimize inventory levels.

Companies like Unilever and Patagonia show that sustainable supply chains strengthen brand reputation and lead to cost savings. These practices also enhance resilience against market fluctuations. You improve operational efficiency and create new revenue opportunities. Over time, you reduce operating costs and remain competitive in challenging markets.

You drive sustainability by adopting digital transformation in your manufacturing operations. You use energy management systems to lower power consumption and carbon emissions. Smart meters and IoT sensors track energy use and automate power management. AI-driven load balancing optimizes energy usage. Cloud-based inventory management reduces excess stock and waste. AI-driven dynamic routing improves transport efficiency. 3D printing minimizes material waste and enables on-demand production. AI-powered sorting systems enhance recycling. Industry 4.0 technologies reduce resource waste and improve efficiency.

| Technology/Strategy | Contribution to Sustainability |

|---|---|

| Energy Management Systems | Lower power consumption and carbon emissions |

| Smart Meters and IoT Sensors | Track energy use and automate management |

| AI-driven Load Balancing | Optimize energy usage dynamically |

| Cloud-based Inventory | Reduce excess stock and waste |

| AI-driven Dynamic Routing | Optimize transport routes, reduce fuel use |

| 3D Printing | Minimize material waste, create on-demand |

| AI-powered Sorting Systems | Improve recycling efficiency |

| Industry 4.0 Technologies | Reduce resource waste, improve efficiency |

You see real-world results. A packaging manufacturer installed IoT sensors and reduced energy costs by 15%. An automotive supplier’s AI system cut unplanned downtime by 20%. An electronics manufacturer used digital twins to optimize energy consumption by 12%. An aerospace manufacturer reduced material usage by 40% with 3D printing.

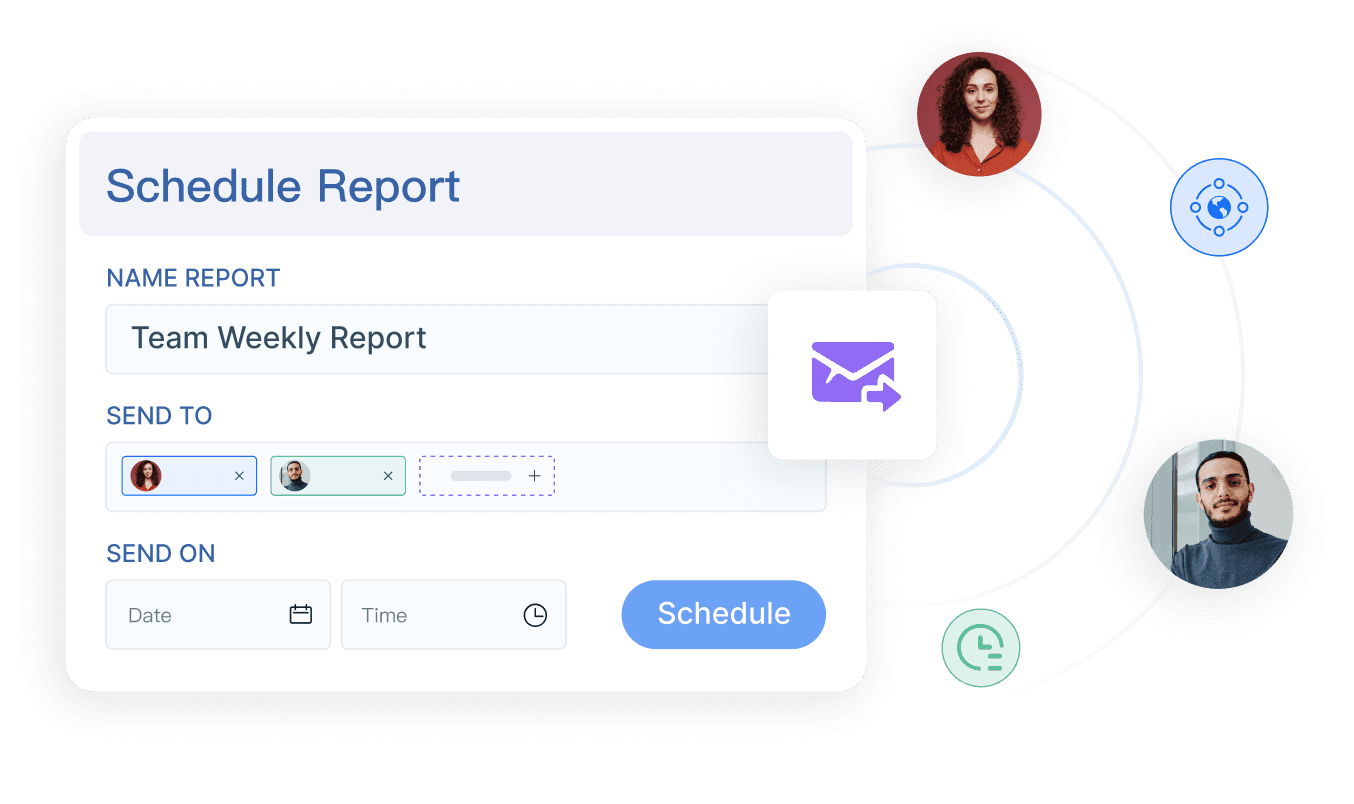

You enhance green manufacturing strategies by implementing intelligent inspection solutions. FineReport supports sustainable processes by enabling paperless inspections and real-time data collection. You use NFC technology to verify the presence of inspection personnel, ensuring data accuracy and reliability. FineReport’s analytics help you identify trends and anomalies in quality data, allowing prompt corrective actions. You configure the system to fit your manufacturing environment, supporting different NFC card formats.

You streamline quality management, reduce environmental impact, and improve operational efficiency. FineReport’s digital platform empowers you to make data-driven decisions, automate reporting, and monitor sustainability metrics. You achieve compliance, reduce waste, and support long-term green manufacturing goals.

Green manufacturing delivers significant environmental benefits when you adopt sustainable practices. You optimize resource efficiency by using raw materials, energy, and water more effectively. You reduce emissions and pollution, which is especially important for industries with high historical emissions. You see advances in energy-efficient machinery and renewable energy sources that help lower your carbon footprint. You also notice a growing demand for skilled professionals who can operate and maintain new sustainable technologies.

You may observe a short-term increase in greenhouse gas emissions and air pollutants when you transition to smart factories. Over time, these changes lead to a reduction in overall environmental impact as you refine your practices and invest in better technology.

Note: The shift toward green manufacturing is essential for minimizing your environmental footprint and meeting regulatory demands.

You gain substantial business value by adopting green manufacturing practices. Companies report enhanced brand image and customer loyalty when they align with environmental values. You lower operational costs by optimizing resource use and improving energy efficiency. You also comply with regulations, which helps you avoid penalties and mitigate risks related to pollution and waste management.

| Benefit | Description |

|---|---|

| Enhanced Brand Image and Customer Loyalty | You improve your brand image and gain a competitive edge as consumers prefer brands that support sustainability. |

| Cost Reduction and Efficiency | You lower operational costs through optimized resource use, energy efficiency, and waste minimization. |

| Regulatory Compliance and Risk Mitigation | You comply with environmental regulations, avoiding penalties and reducing risks associated with pollution and waste. |

| Long-term Viability and Market Opportunities | You position your company to adapt to market changes and consumer preferences, ensuring longevity and relevance in a changing business landscape. |

Green manufacturing practices within a sustainable supply chain reduce your environmental footprint by minimizing waste, maintaining resources, and curbing pollution throughout the manufacturing cycle.

You maximize business value by integrating sustainable practices at every production stage. You conduct thorough sustainability assessments to identify areas for improvement. You modify processes to boost efficiency and lower costs. You adopt energy-efficient technologies and effective waste management strategies. You also source raw materials sustainably.

You see that the core principles of green manufacturing—energy efficiency, waste reduction, and optimized raw material usage—help you achieve both environmental and business goals.

You see green manufacturing as a way to conserve energy, reduce pollutants, and use non-toxic materials. The strategies you learned—energy efficiency, waste reduction, and sustainable supply chains—help you save costs and optimize resources. FineReport supports your efforts by enabling data-driven management and paperless inspections.

| Key Aspect | Description |

|---|---|

| Conservation of energy and alternative energy use | Focuses on reducing energy consumption and encourages renewable energy sources. |

| Reduction of environmental pollutants | Aims to minimize pollutants released into the environment through eco-friendly methods. |

| Incorporation of non-toxic materials | Emphasizes the use of safe, sustainable, and recyclable materials. |

| Recycling and waste reduction | Promotes recycling and waste management to conserve materials and reduce waste. |

You can increase profitability, gain tax incentives, and support your local economy by adopting these practices. Start your journey toward a more sustainable and efficient manufacturing future.

How to Do Retention Analysis for Business Success

What is Pareto Chart and How Does it Work

How DuPont Analysis Helps You Understand Your Business

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

9 Best Supply Chain Tools for Smarter Management in 2026

Find the best supply chain tools for 2025 to boost efficiency, gain real-time insights, and achieve smarter management for your business.

Lewis

Dec 18, 2025

Top 10 Supply Chain Tracking Software for 2026

Compare the top supply chain tracking software for 2026 to boost visibility, automate workflows, and leverage AI analytics for smarter decisions.

Lewis

Dec 18, 2025

Top 10 Supply Chain Management Software for Small Businesses

See the top 10 supply chain management software comparison for small businesses in 2026. Compare features, pricing, and scalability to find your best fit.

Lewis

Dec 18, 2025